Anti-vibration butterfly valve

An anti-vibration, butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

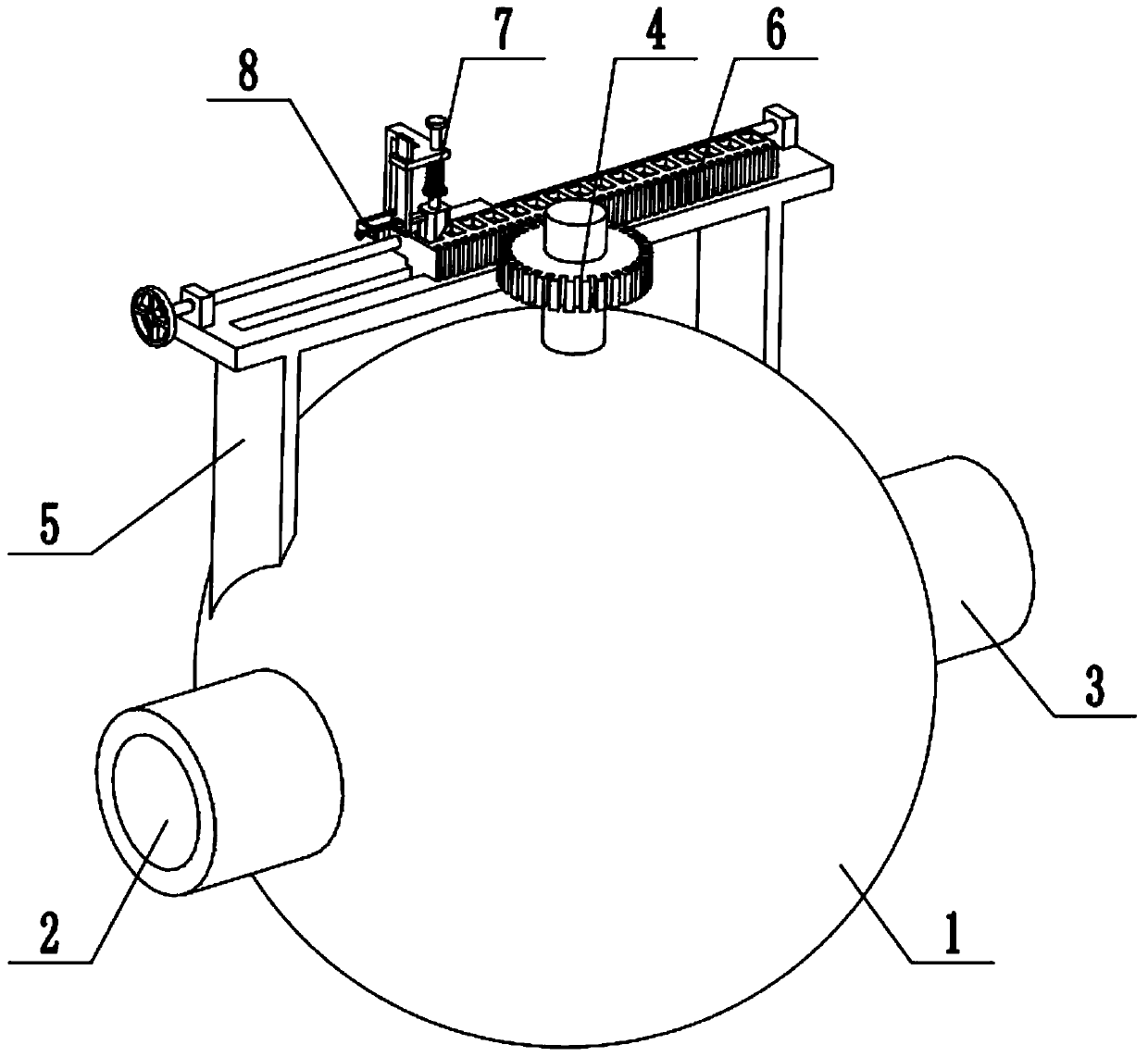

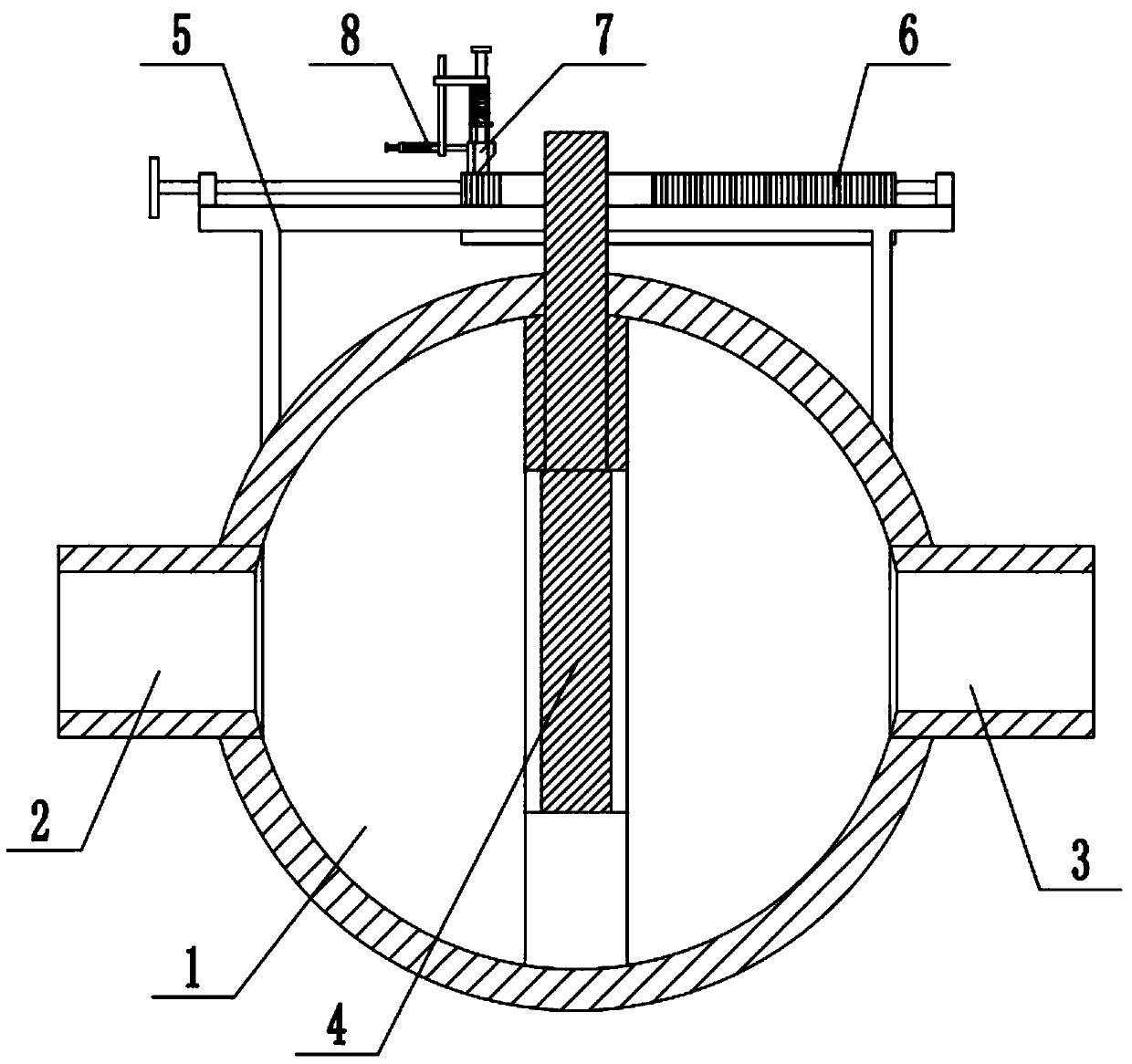

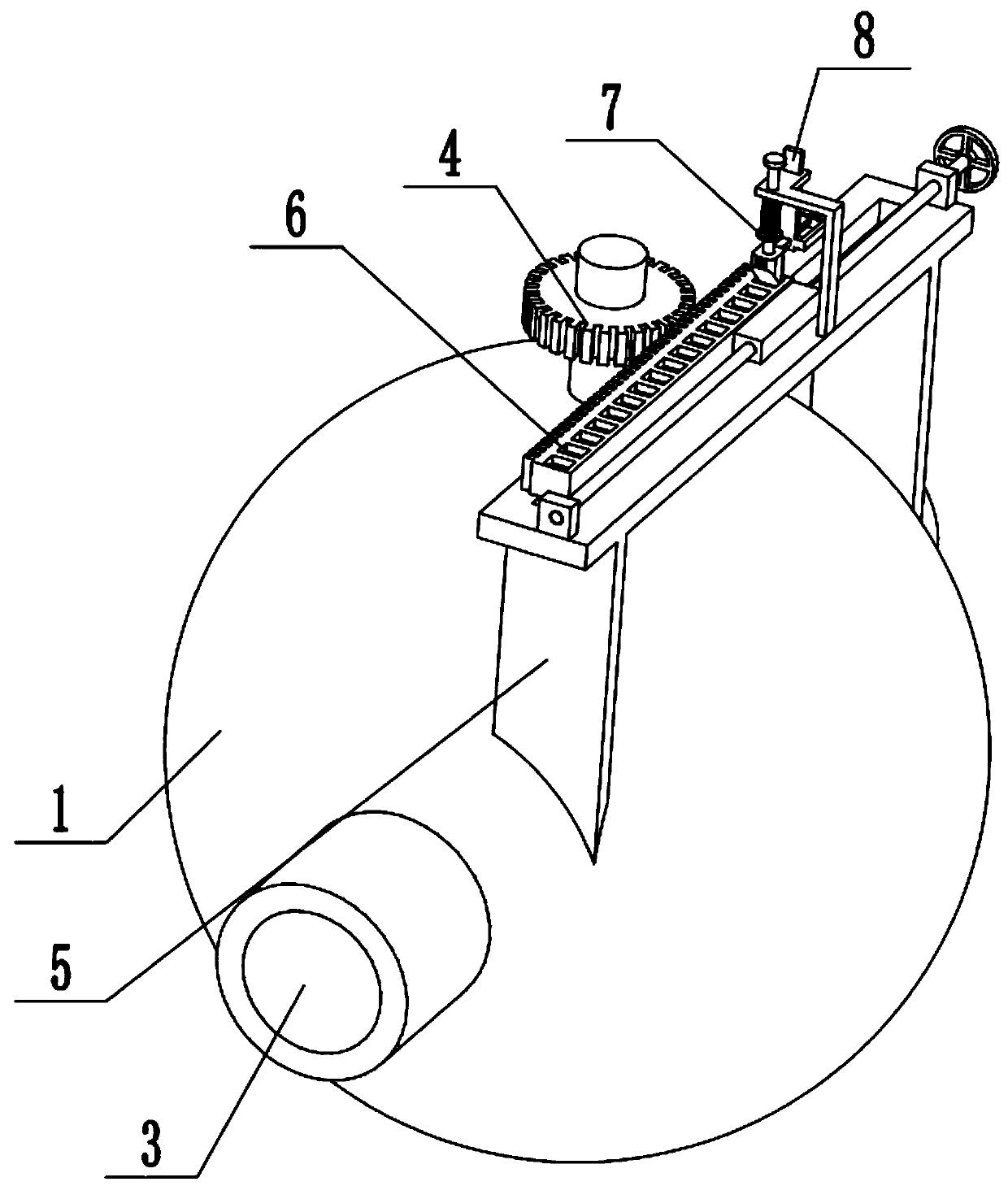

[0028] Combine below Figure 1-11 Describe this embodiment, an anti-vibration butterfly valve, including a valve body 1, a water inlet pipe 2, a drain pipe 3, a butterfly plate assembly 4, a frame body 5, a rack 6, a clip 7 and a limit mechanism 8, the valve The left end of the body 1 is fixedly connected to and connected to the water inlet pipe 2, the right end of the valve body 1 is fixedly connected to and connected to the drain pipe 3, the butterfly plate assembly 4 is arranged in the middle of the valve body 1, the frame body 5 is fixedly connected to the upper end of the valve body 1, and the teeth The bar 6 is arranged on the frame body 5, the butterfly plate assembly 4 is connected to the rack body 6 in transmission, the clip 7 is fixedly connected to the frame body 5, the clip 7 is blocked on the rack body 6, and the limit mechanism 8 is slidably connected to the frame body 5. On the clip 7 , the limit mechanism 8 is connected with the clip 7 . When the present inven...

specific Embodiment approach 2

[0030] Combine below Figure 1-11 To illustrate this embodiment, the middle part of the inner side of the valve body 1 is fixedly connected to the butterfly plate seat 1-1, the center of the butterfly plate seat 1-1 is provided with a liquid hole 1-2, and the shaft slide groove 1-3 is provided through the valve body. The upper end of the body 1 and the upper end of the disc seat 1-1, the rotating shaft chute 1-3 communicate with the liquid hole 1-2.

specific Embodiment approach 3

[0032] Combine below Figure 1-11 To illustrate this embodiment, the butterfly plate assembly 4 includes a butterfly plate 4-1, a rotating shaft 4-2 and a gear 4-3; the upper end of the butterfly plate 4-1 is fixedly connected to the rotating shaft 4-2, and the rotating shaft 4-2 is fixedly connected to the The gear 4-3 and the butterfly plate 4-1 are located in the liquid hole 1-2, the circular end surface of the butterfly plate 4-1 is provided with a sealing rubber pad, and the rotating shaft 4-2 is sealed and slidably connected to the rotating shaft chute 1-3 Inside, the gear 4-3 is connected with the gear rack 6 in meshing transmission. The butterfly plate 4-1 is located in the liquid hole 1-2, and the liquid hole 1-2 is blocked to be in a closed state. When the rack 6 moves left and right, it drives the gear 4-3 to rotate, and the gear 4-3 drives the rotating shaft 4-2 to rotate. , the rotating shaft 4-2 drives the butterfly plate 4-1 to rotate, thereby realizing the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com