Novel GaN heterojunction field effect transistor

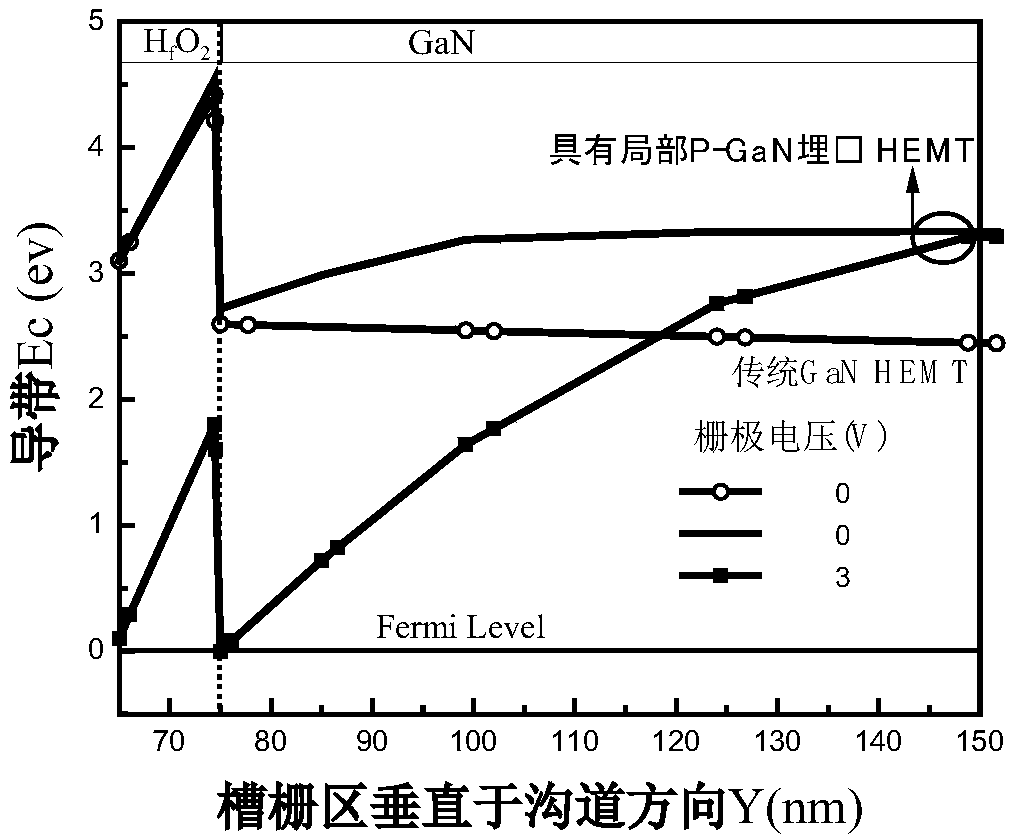

A heterojunction field effect, transistor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of threshold voltage hysteresis, weakened control, increased on-resistance, etc., to reduce the maximum peak electric field, reduce Leakage current, the effect of improving breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] The present invention has been described in detail in the part of the summary of the invention, and will not be repeated here. In order to further illustrate the feasibility of the scheme of the present invention in practical application, the manufacturing process that can prepare the structure of the present invention is proposed below:

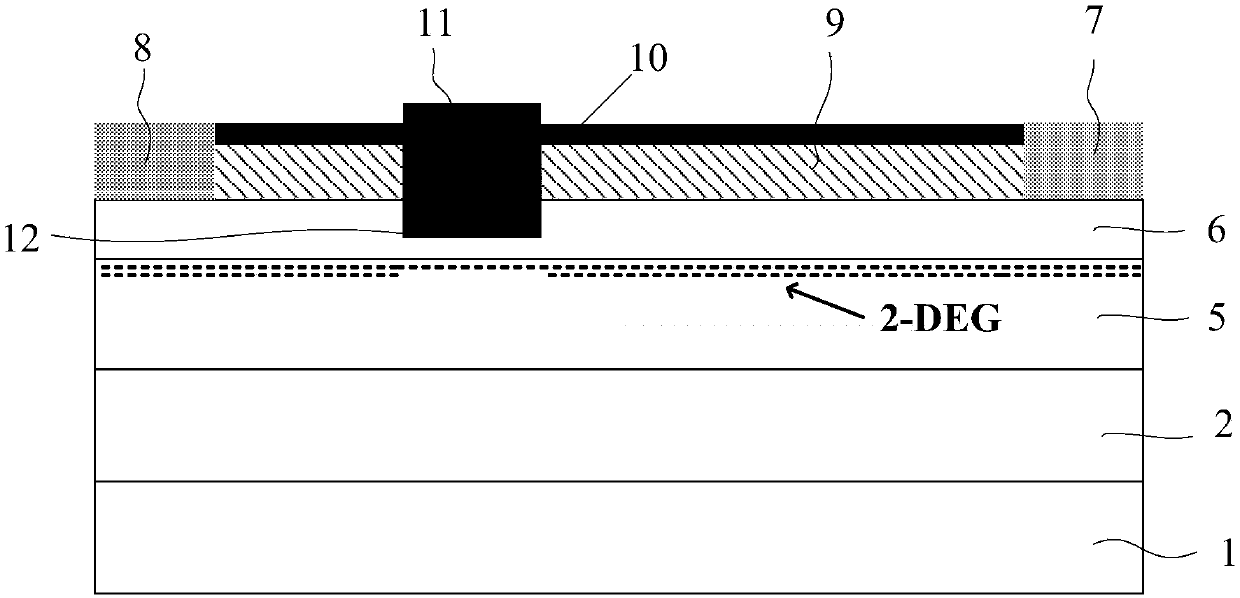

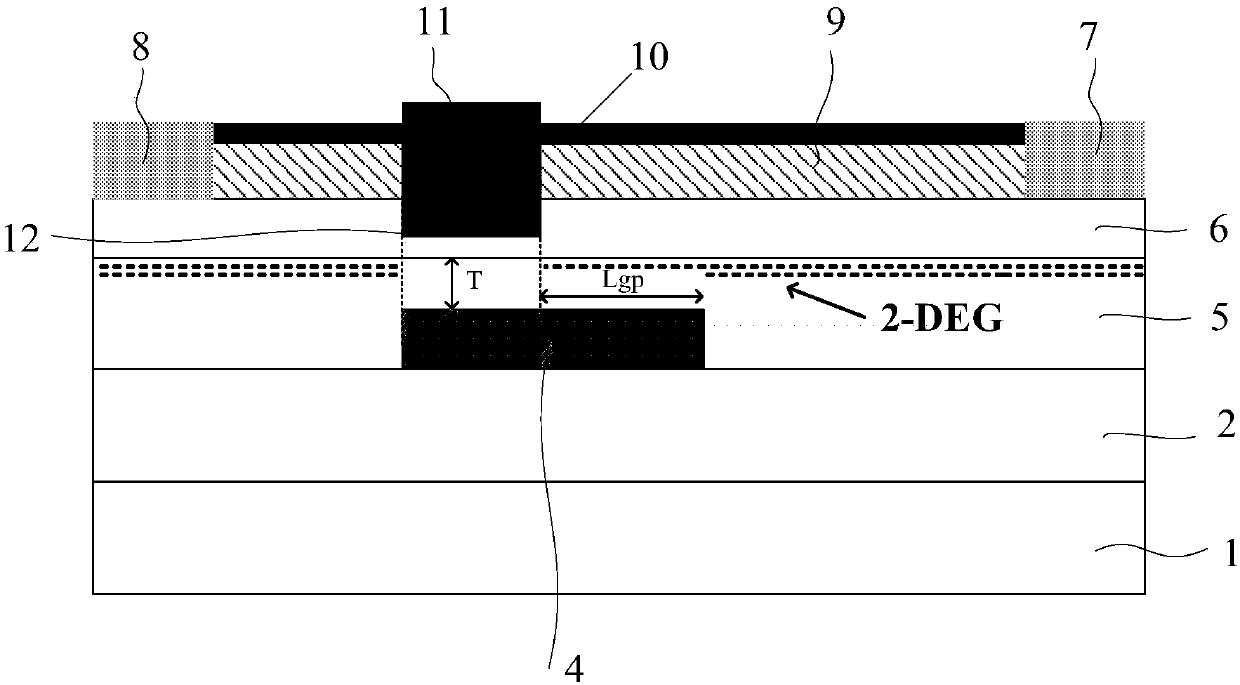

[0039] On a Si, SiC, sapphire or GaN substrate 1, a GaN nucleation buffer layer 2 and a P-type GaN buried layer 3 are sequentially grown by metal-organic chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE), such as Figure 8 ;

[0040] Etching the P-type GaN buried layer 3 into a local P-type GaN buried layer 4 by using one or a combination of dry etching and oxidation wet etching, such as Figure 9 ;

[0041] The i-type or n-type GaN channel layer 5 and the heterojunction barrier layer 6 are epitaxially grown in sequence by the method of secondary epitaxy, and the evaporation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com