HEMT device with multi-metal gate structure and preparation method thereof

A metal structure and gate structure technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor repeatability, difficult and precise control of electron beam deposition, etc., to improve the breakdown voltage and improve the dynamic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

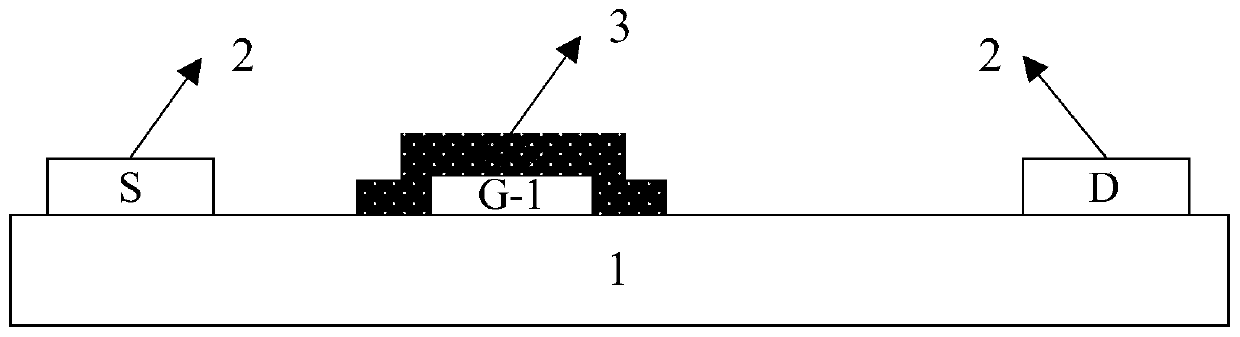

[0029] This embodiment provides a HEMT device with a multi-metal gate structure, such as image 3 As shown, the device includes an AlGaN / GaN epitaxy 1, the two ends of the upper surface of the AlGaN / GaN epitaxy are respectively connected to the source and drain electrodes 2, and the source and drain electrodes 2 are provided with a gate electrode 3 near the source side, and the gate electrode 3 is the first A layer of metal Ti is deposited by electron beam evaporation, and the second layer of metal Ni of the gate electrode 3 is deposited by magnetron sputtering without additional photolithography steps. The contact metal structure is Ni / Ti / Ni. image 3 G-1 in represents the first layer of metal, and G-2 represents the second layer of metal.

[0030] This embodiment also provides a method for preparing a HEMT device with a multi-metal gate structure, comprising the following steps:

[0031] (1) In AlGaN / GaN epitaxy (the epitaxial layer before the source-drain contact electrod...

Embodiment 2

[0035] This embodiment provides a HEMT device with a multi-metal gate structure, such as image 3 As shown, the device includes an AlGaN / GaN epitaxy 1, the two ends of the upper surface of the AlGaN / GaN epitaxy are respectively connected to the source and drain electrodes 2, and the source and drain electrodes 2 are provided with a gate electrode 3 near the source side, and the gate electrode 3 is the first A layer of metal TiN is deposited by electron beam evaporation, and the second layer of metal W of the gate electrode 3 is deposited by magnetron sputtering without additional photolithography steps. The contact metal structure is W / TiN / W.

[0036] This embodiment also provides a method for preparing a HEMT device with a multi-metal gate structure, comprising the following steps:

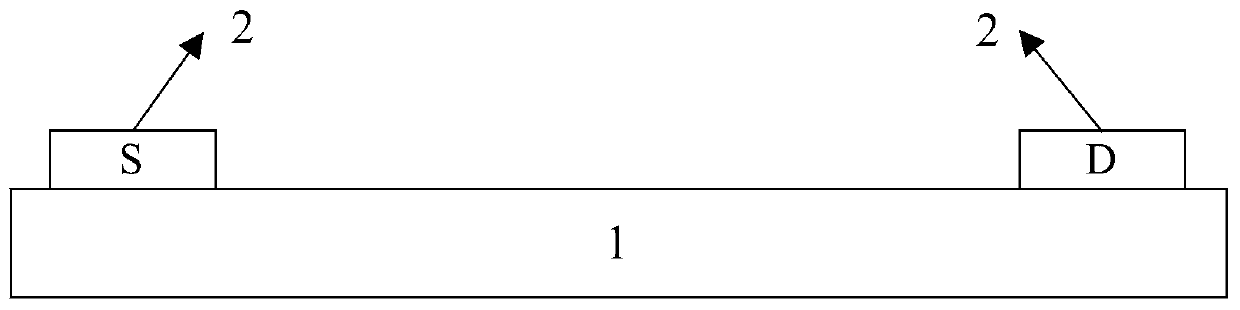

[0037] (1) Define the source-drain electrode window on the AlGaN / GaN epitaxy 1, prepare the source-drain electrode 2 and perform annealing to form an ohmic contact, such as figure 2 shown;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com