Mould and method for manufacturing shoe sole, shoe pad, heel and elastic pole with spring shock absorption

A technology of elastic columns and molds, which is applied to home appliances, other home appliances, household components, etc., can solve the problems of poor firmness, high cost, and no spring shoes, etc., to increase firmness, prevent side torsion, and be simple and operable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

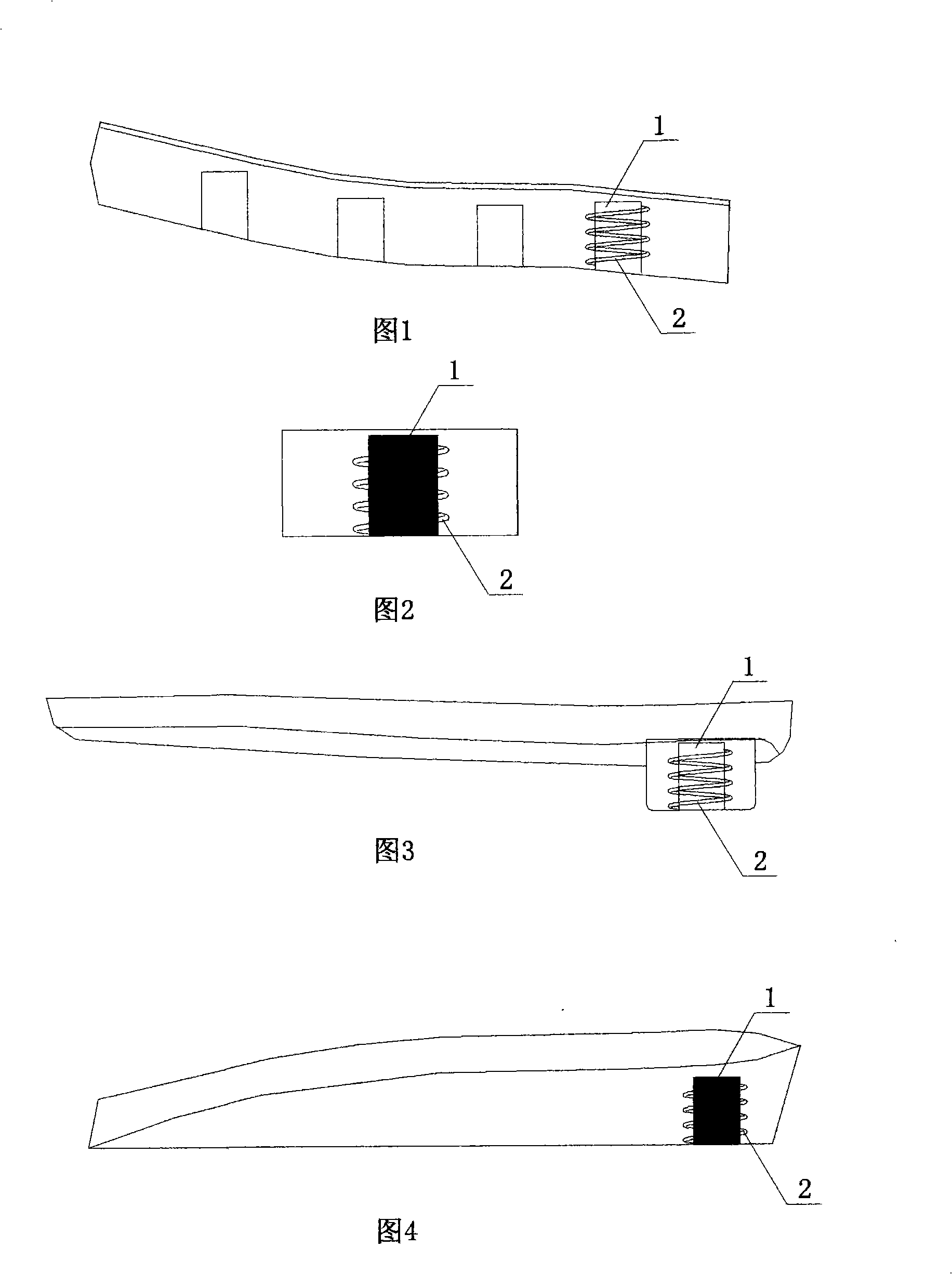

[0017] As shown in Fig. 1 to Fig. 4, an iron column body 1 is arranged in the mold cavity of the shoe sole, insole, shoe heel and elastic column according to the present invention, and the spring 2 is sleeved on the iron column body. Due to the high pressure in the mold, it is easy to cause the spring to shift. When designing the mold, we fix one end of the iron column at the bottom of the mold, and the other end goes up to the top of the mold or does not need to go to the top. The iron column is a cylinder. Or triangular prism or square prism. The iron cylinder is slightly smaller than the inner diameter of the spring, so that the shoe material can cover the inner diameter of the spring and the spring part is exposed. The customized spring is slightly shorter than the height of the mold. In this way, the top of the produced product is sealed with a layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com