Anti-deforming stress-balancing method for furniture table-board

A kind of anti-deformation and balance technology, which is applied to the legs of general furniture, furniture parts, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

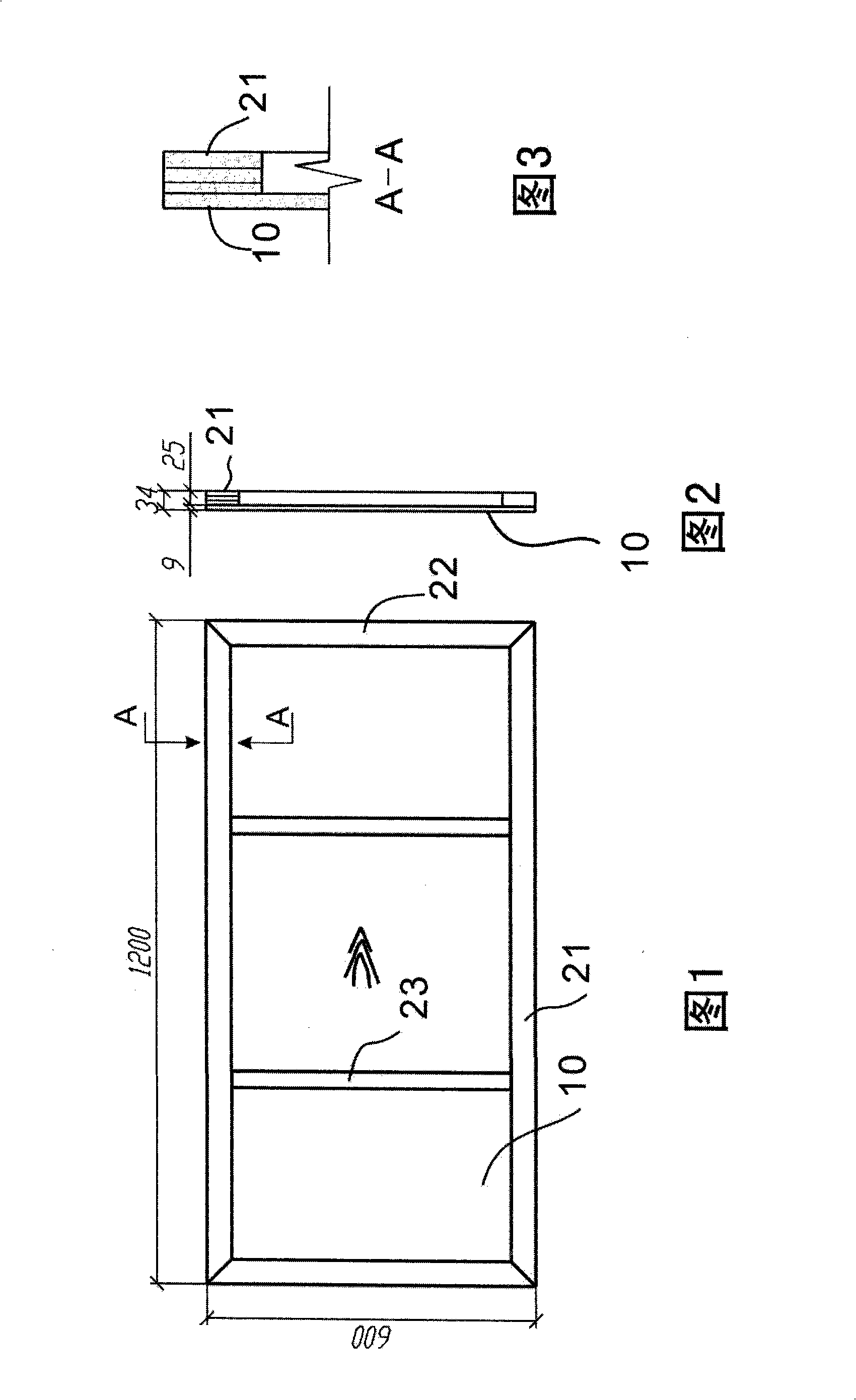

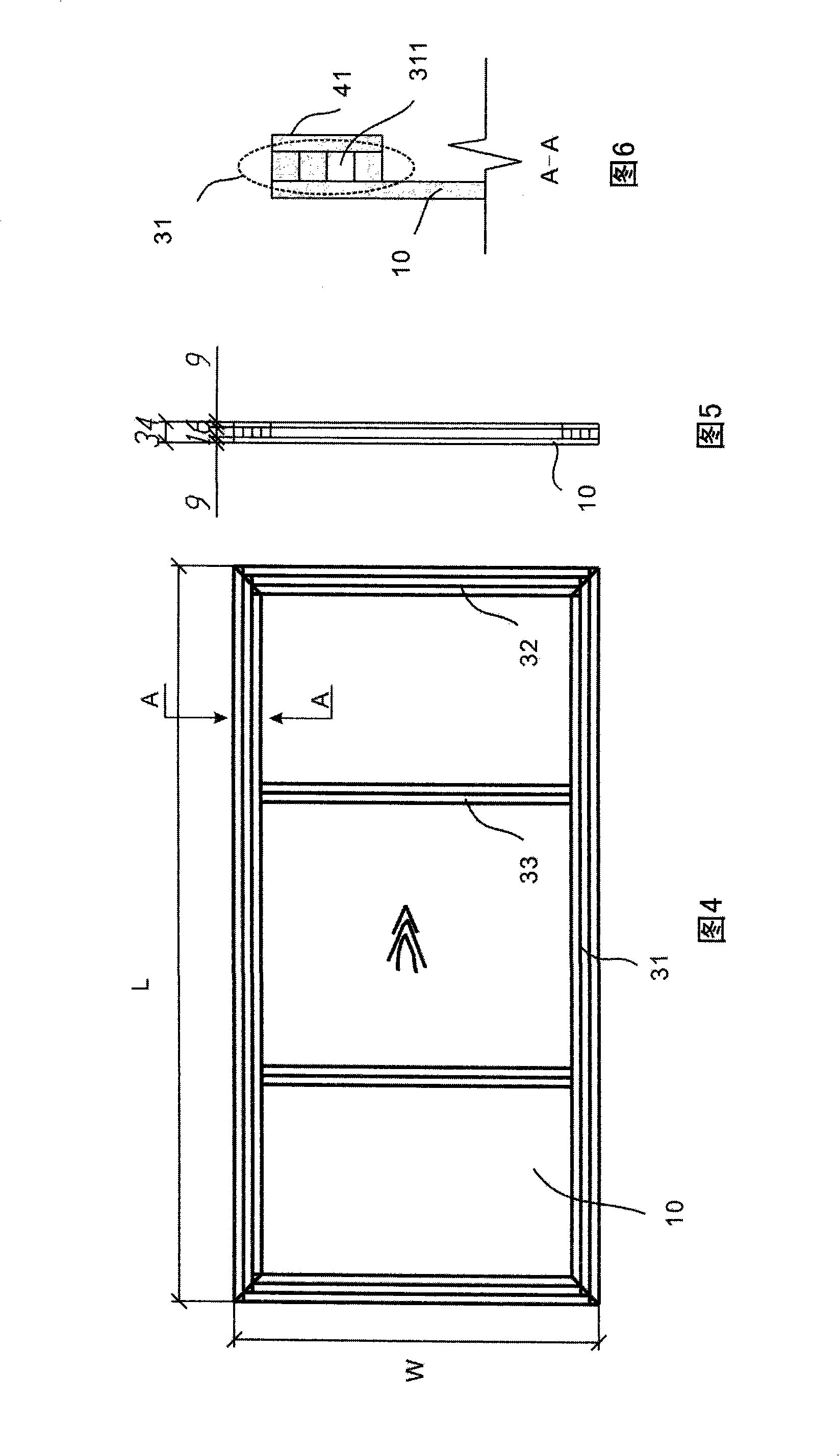

[0027] The present invention will be further described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0028] Referring to Figures 4 to 6, a method for anti-deformation stress balance of furniture desktops is implemented. The first implementation method includes steps:

[0029] ①. Making slats 311 with a section length-to-width ratio greater than 1.5;

[0030] 2. Lay the planes of at least two or more slats 311 to the plane, and bond them with an adhesive; form a frame slat, and the frame slat 31 has a first wide surface and a second wide surface;

[0031] 3. Glue at least one frame lath on the back side of the desktop 10, and what is glued to the back side of the desktop is the first wide surface.

[0032] After step ③, glue at least one layer of balance slats 41 on the second wide surface of the frame slats.

[0033] The second implementation method consists of steps:

[0034] ①. Making slats 311 with a section length-to-width rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com