Arm for automatic machine

A technology of automatic machinery and arms, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problem that the fork arm hits the load placed on the lower layer, and the front end may touch the load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described below with reference to the drawings.

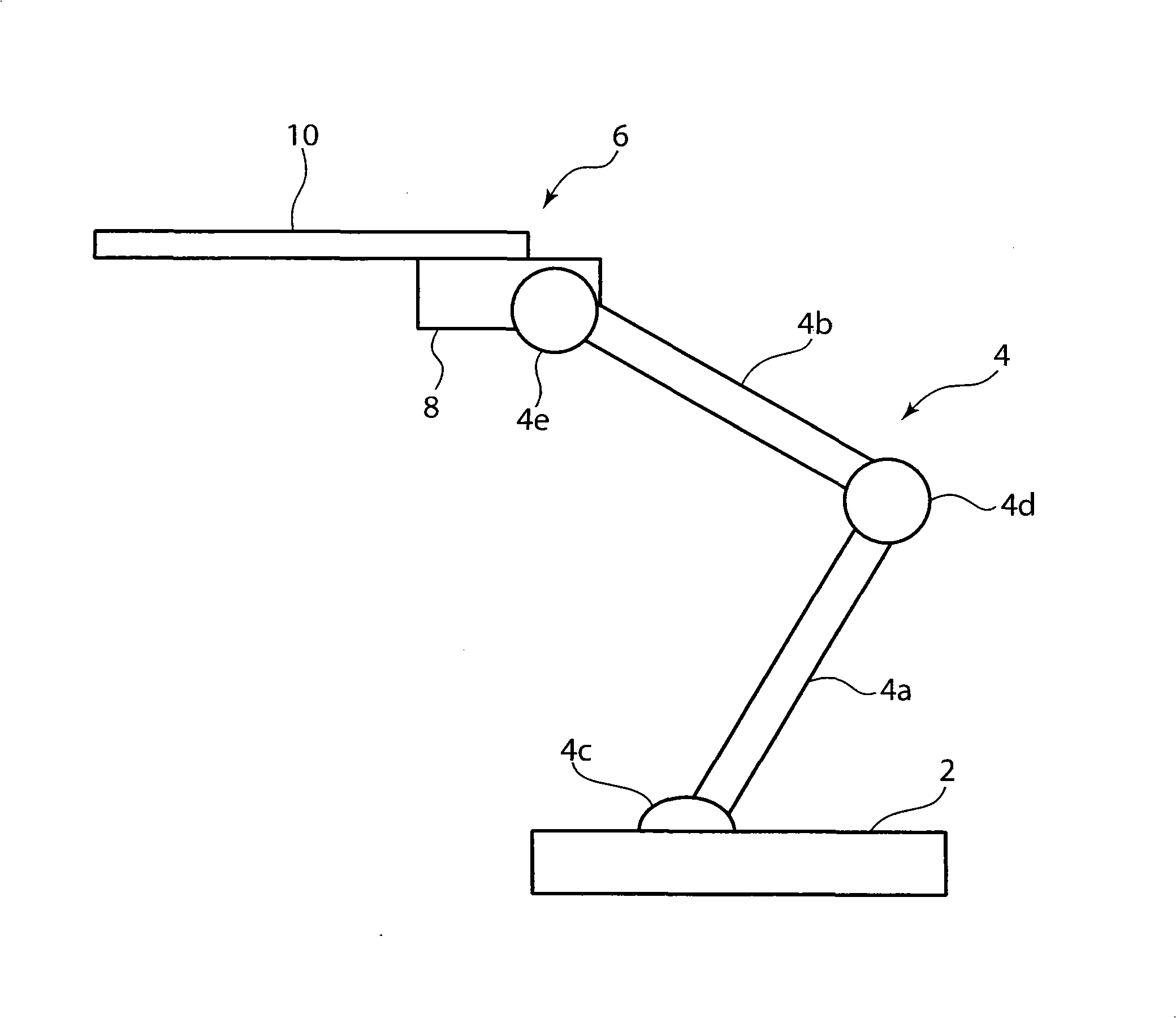

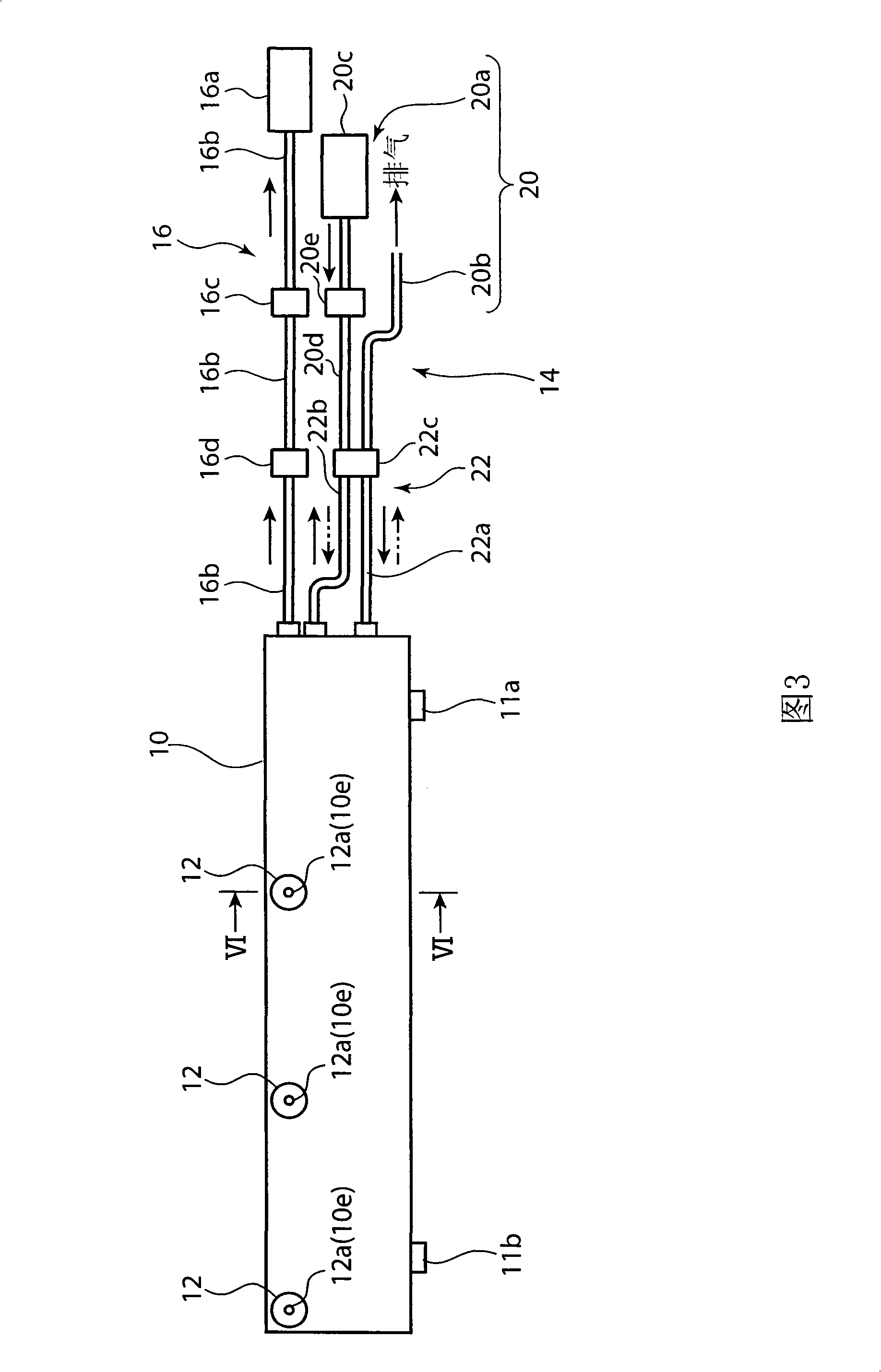

[0046] First, refer to Figure 1 to Figure 8 The structure of the robot arm 6 according to the embodiment of the present invention and a transfer robot including the robot arm 6 will be described.

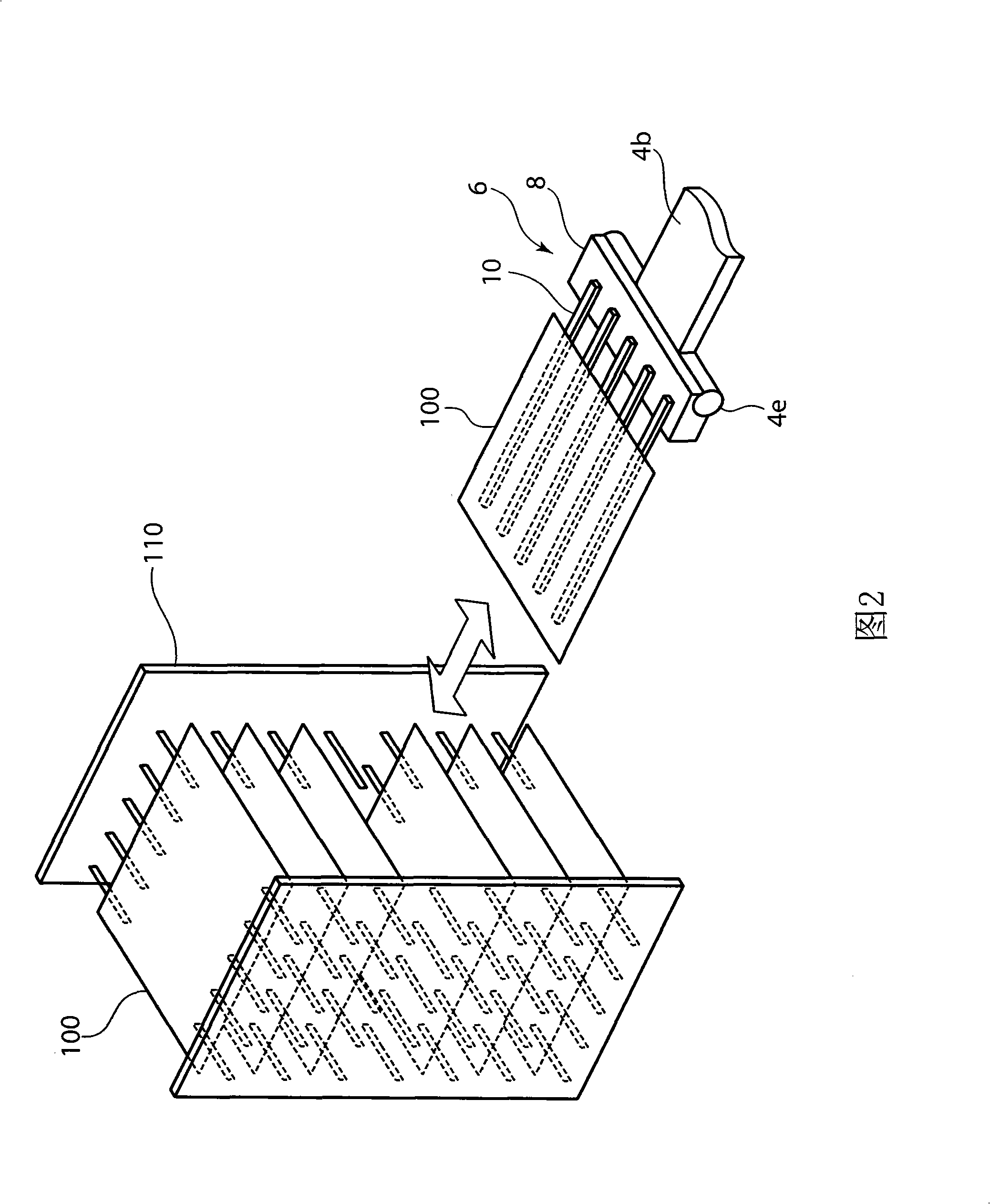

[0047] The robot for conveyance of this embodiment is an apparatus for mounting the glass substrate 100 for liquid crystal displays as a conveyance on the fork (fork, which will be described later) 10 thereof, and conveying the glass substrate 100 . As shown in FIG. 2 , this transfer robot is used to place the glass substrate 100 on each layer of the storage rack 110 or to take out the glass substrate 100 placed on each layer of the storage rack 110 . and, if figure 1 As shown, the transfer robot includes a base part 2, an arm part 4, and an arm 6 for the robot.

[0048] The base portion 2 is a base portion of a conveyance robot, and the arm portion 4 is mounted on the base port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com