Brazed pipe and production method thereof

A manufacturing method and brazing technology, which is applied in the direction of manufacturing tools, welding equipment, tubular objects, etc., can solve problems such as poor brazing, troublesome operations, and complicated manufacturing operations of brazed pipes, and achieve the effect of simple manufacturing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0055] In this embodiment, the present invention is applied to the heat exchanger shown in FIG. 7 , and in the following description, the same reference numerals are assigned to the same parts as in FIG. 7 .

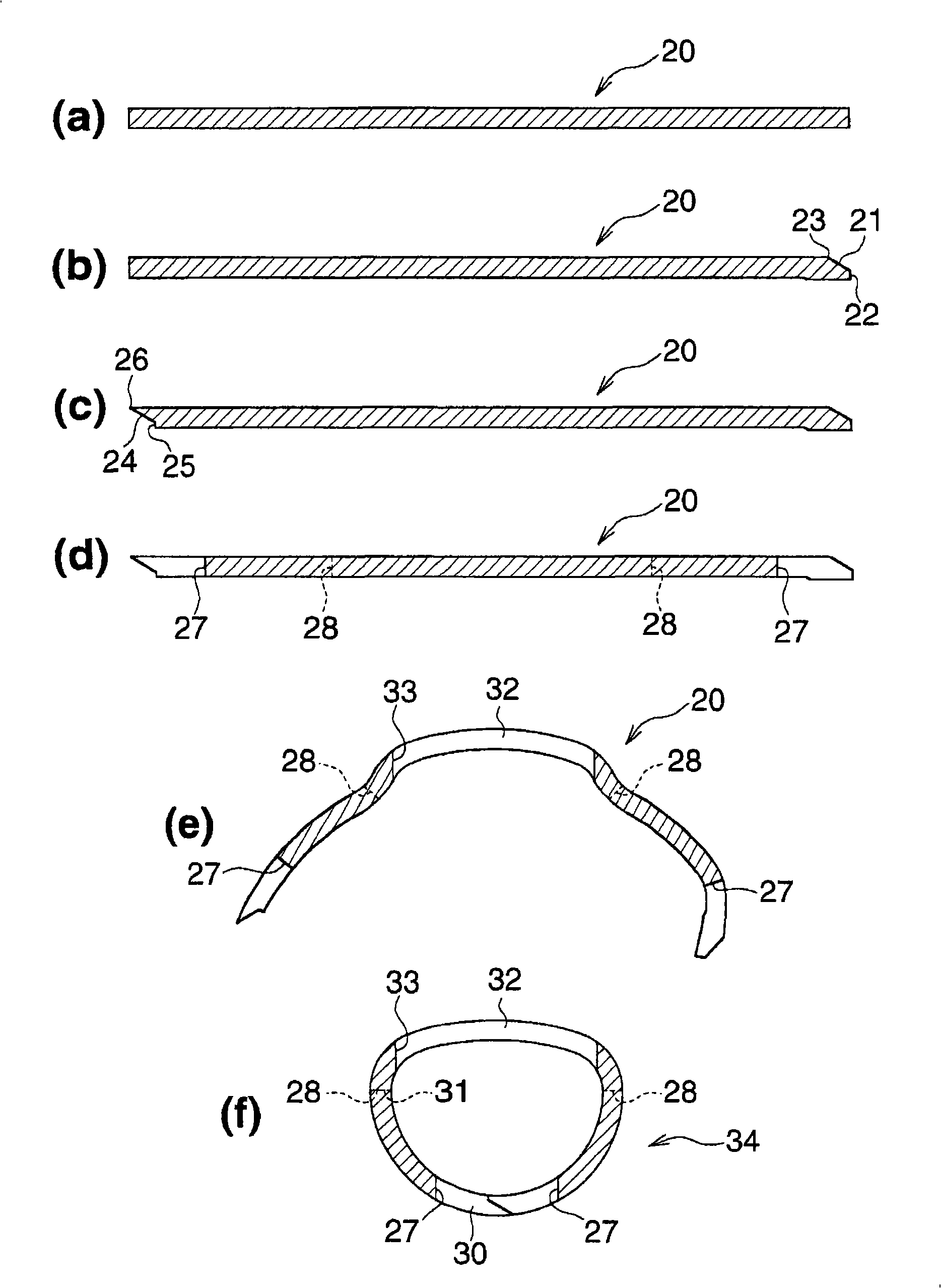

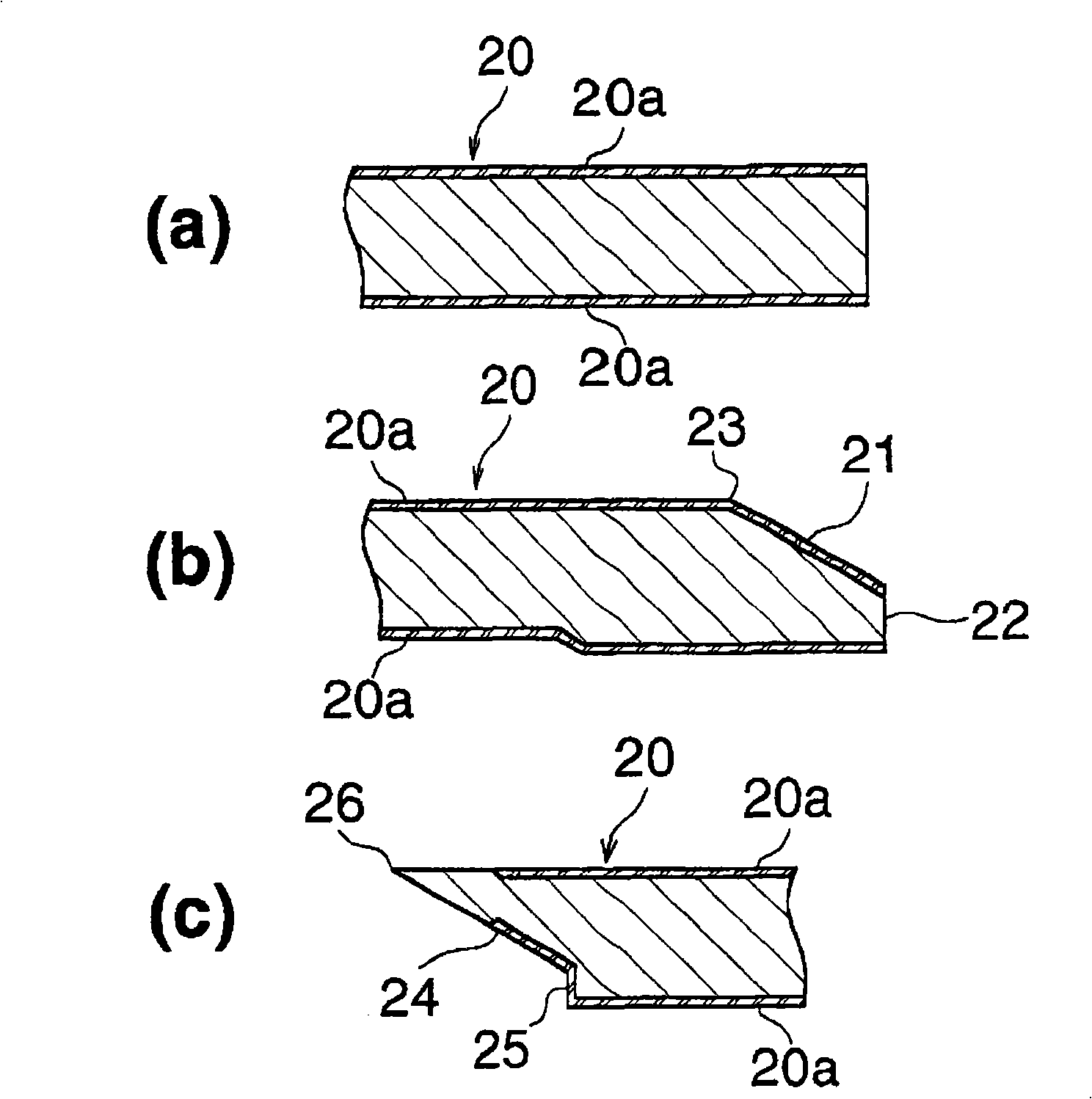

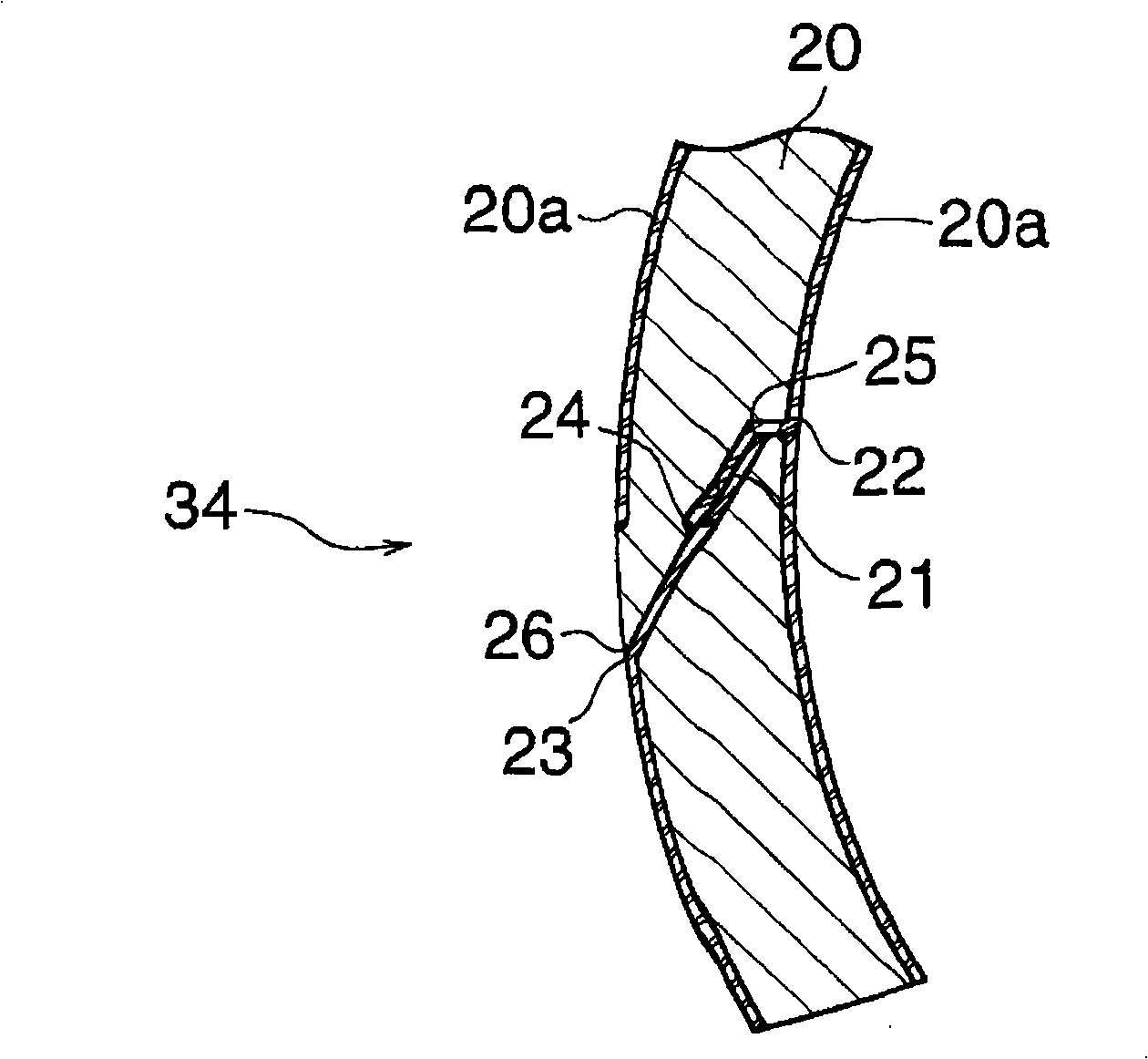

[0056] figure 1 as well as figure 2 Indicates the manufacturing method of the brazed pipe used in the water tank, image 3 ~ Fig. 6 shows the manufacturing method of the heat exchanger.

[0057] First, a blank 20 made of a brazing sheet having an aluminum brazing material layer 20a on both sides is prepared (refer to figure 1 (a) and figure 2 (a)). Next, on the right side edge of the base plate 20, for example, press work is performed from the top and bottom, thereby forming a front end (right end) on the upper surface of the base plate 20 from the top (first surface) side of the blank plate 20 to the bottom ( The first inclined surface 21 inclined on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com