Beating-rubbing type millet threshing mechanism

A threshing device and millet technology, which is applied in the field of agricultural machinery, can solve the problems of high loss rate, low cleaning rate, and high crushing rate, and achieve the effects of reducing loss rate and crushing rate, increasing cleaning rate, and improving threshing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

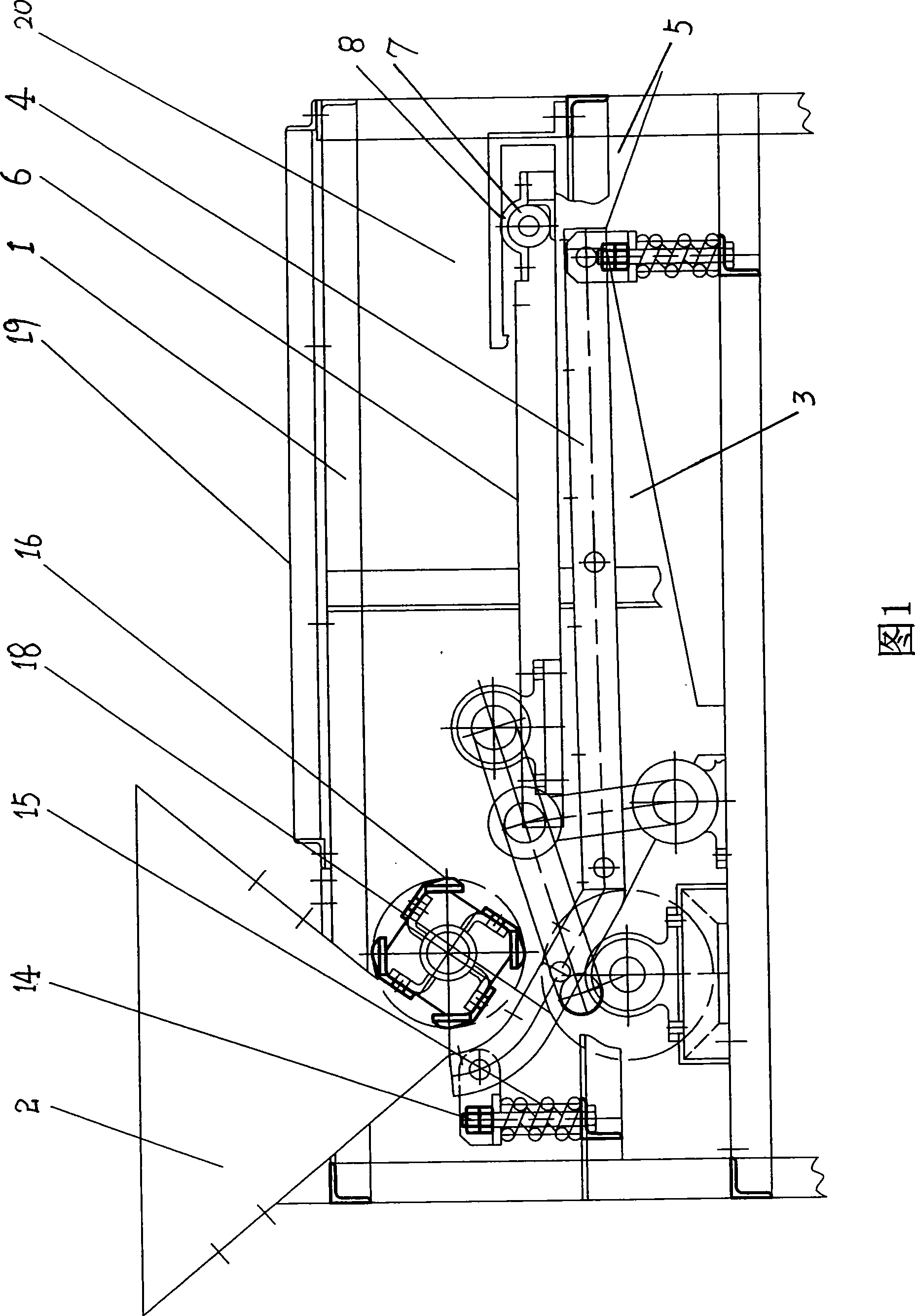

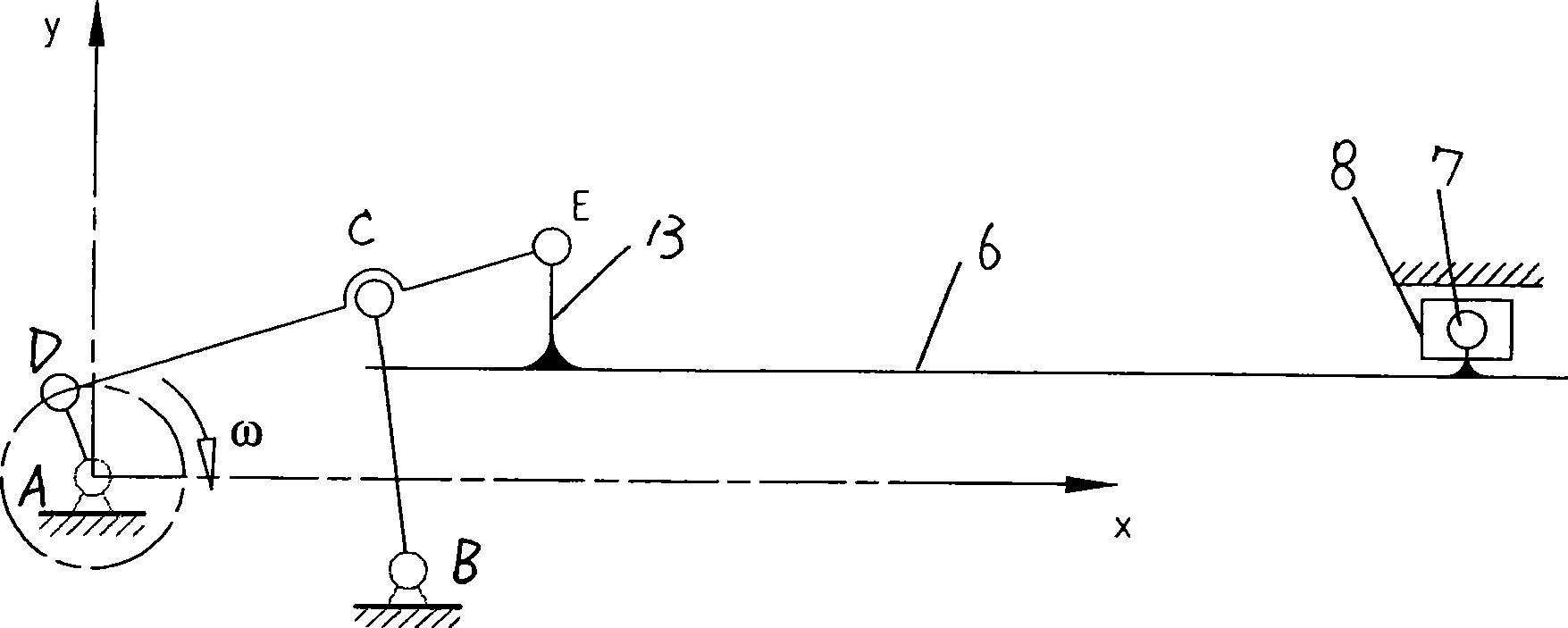

[0021] The pat-rubbing millet threshing device, as shown in Figure 1, includes a sealed frame 1, a feeding hopper 2 is fixed on the upper side of the frame, and a material feeding device is set on the lower side of the feeding hopper 2, which is fed by a rod-type closed drum Device 16; the frame 1 is also provided with a sieve-type threshing plate 4 with a millet discharge port 3 below, and the threshing plate 4 is elastically supported on the frame 1 by adjusting bolts 14 and springs 15 sleeved on it and adjusting shims. On the upper part, one end of the threshing board 4 is located below the feeding hopper 2, and the other end is provided with a waste discharge outlet 5; above the threshing board 4 is provided a movable pat and washboard 6, one end and both sides of the pat and washboard 6 are respectively connected with a four-bar drive mechanism, and the other end It is connected with the sliding block 7 and is located in a slideway 8 fixed on the frame, and the four-bar drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com