Pressure-limiting valve integrated with high back pressure exhaust brake valve

A technology of exhaust brake valve and pressure limiting valve, which is applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of exhaust valve damage, exhaust valve secondary opening, etc., and achieve improved braking power and optimized Effect of exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

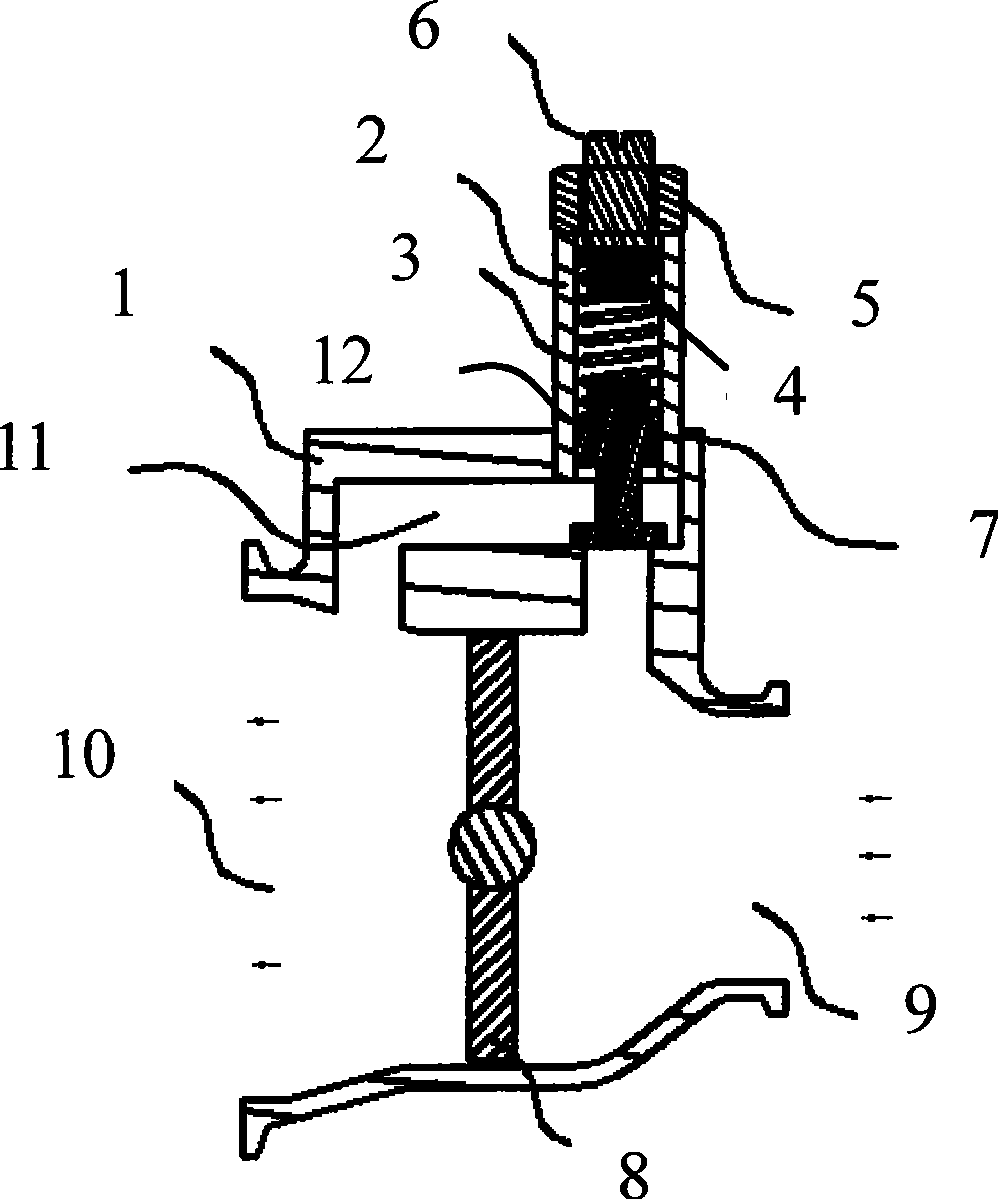

[0015] Such as figure 1 It can be seen that the spring seat 4, spring 3, and valve disc 7 are installed in the valve body 2 of the pressure limiting valve in sequence, the valve body 2 of the pressure limiting valve and the valve body 1 of the exhaust brake valve are installed together, and the valve disc 7 is sealed in the On the valve body 2 of the pressure limiting valve and the valve body 1 of the exhaust brake valve, one end of the adjustment bolt 6 is in contact with the spring seat 4, and the nut 5 is installed on the other end of the adjustment bolt 6, on the valve body of the exhaust brake valve. The body 1 has a bypass passage 11, the entrance of the bypass passage 11 is sealed by the valve disc 7, the outlet of the bypass passage 11 is connected with the exhaust pipe, and the adjustment bolt 6, the nut 5 and the spring seat 4 are used to adjust the preload of the spring 3. There is a convex edge 12 at the end where the disc 7 is in contact with the spring 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com