Diesel engine DPF cycle cleaning regeneration device

A regeneration equipment, DPF technology, applied in the direction of filter regeneration, filtration separation, membrane filter, etc., can solve the problems of thermal damage of filter body, reduction of DPF particle collection capacity, increase of exhaust pipe back pressure, etc., to reduce maintenance Or replacement cost, recovery of particle refill performance, effect of improving exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

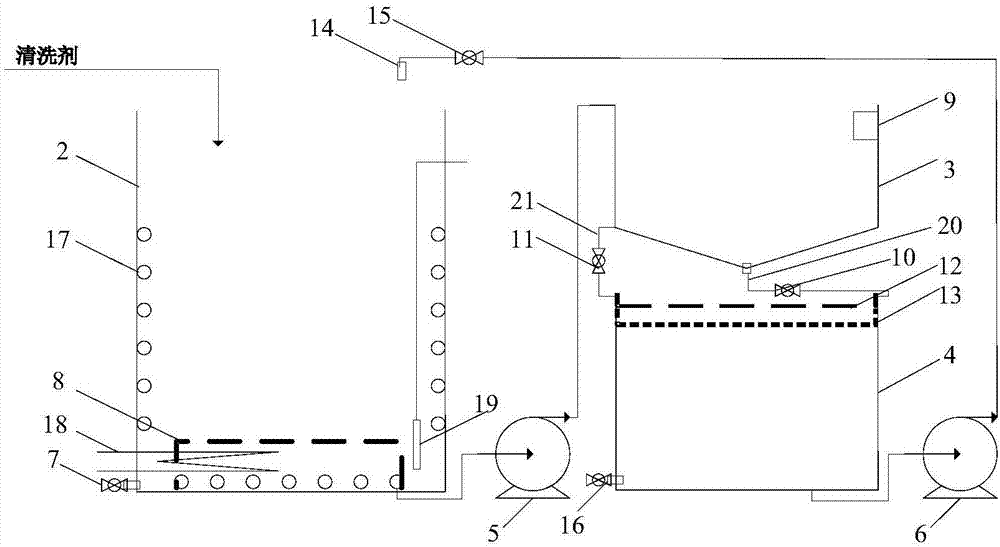

[0012] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0013] like figure 1 As shown, the diesel engine DPF cycle cleaning and regeneration equipment includes a chassis 1, and the chassis 1 is equipped with a cleaning tank 2, a water purification tank 3 and a buffer tank 4. The cleaning tank 2 is connected with the clean water tank 3 through the first centrifugal pump 5, and the clean water tank 3 is connected to the water pipe through the water pipe. The buffer tank 4 is connected, the buffer tank 4 is connected with the cleaning tank 2 through the second centrifugal pump 6 , and the clean water tank 3 is placed above the buffer tank 4 . The cleaning tank 2 is provided with a metal grid cleaning frame 8 , an ultrasonic vibrator 17 , an electric heating and temperature sensing system 18 , and a liquid level sensor 19 . The metal grid cleaning rack 8 is used to place the diesel engine DPF, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com