Transfer belt unit and image forming apparatus using the same

一种转印带、图像的技术,应用在图像形成装置,转印带装置领域,能够解决调色剂易发生凝集、二次转印性恶化、二次转印性低下等问题,达到提高机械上耐久性、成本降低、抑制凝集的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

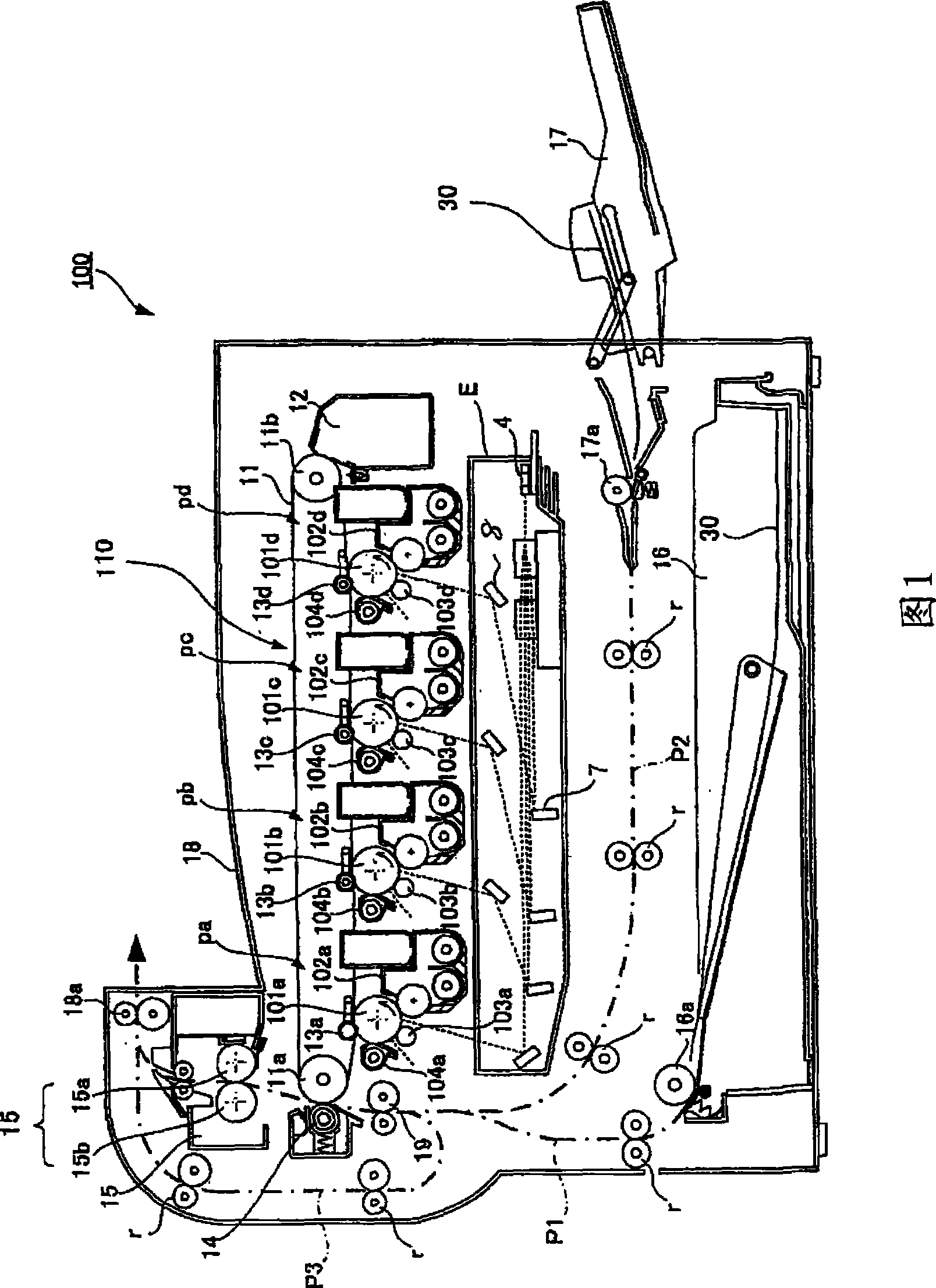

[0044] FIG. 1 is an explanatory diagram showing the configuration of an image forming apparatus according to an embodiment of the present invention.

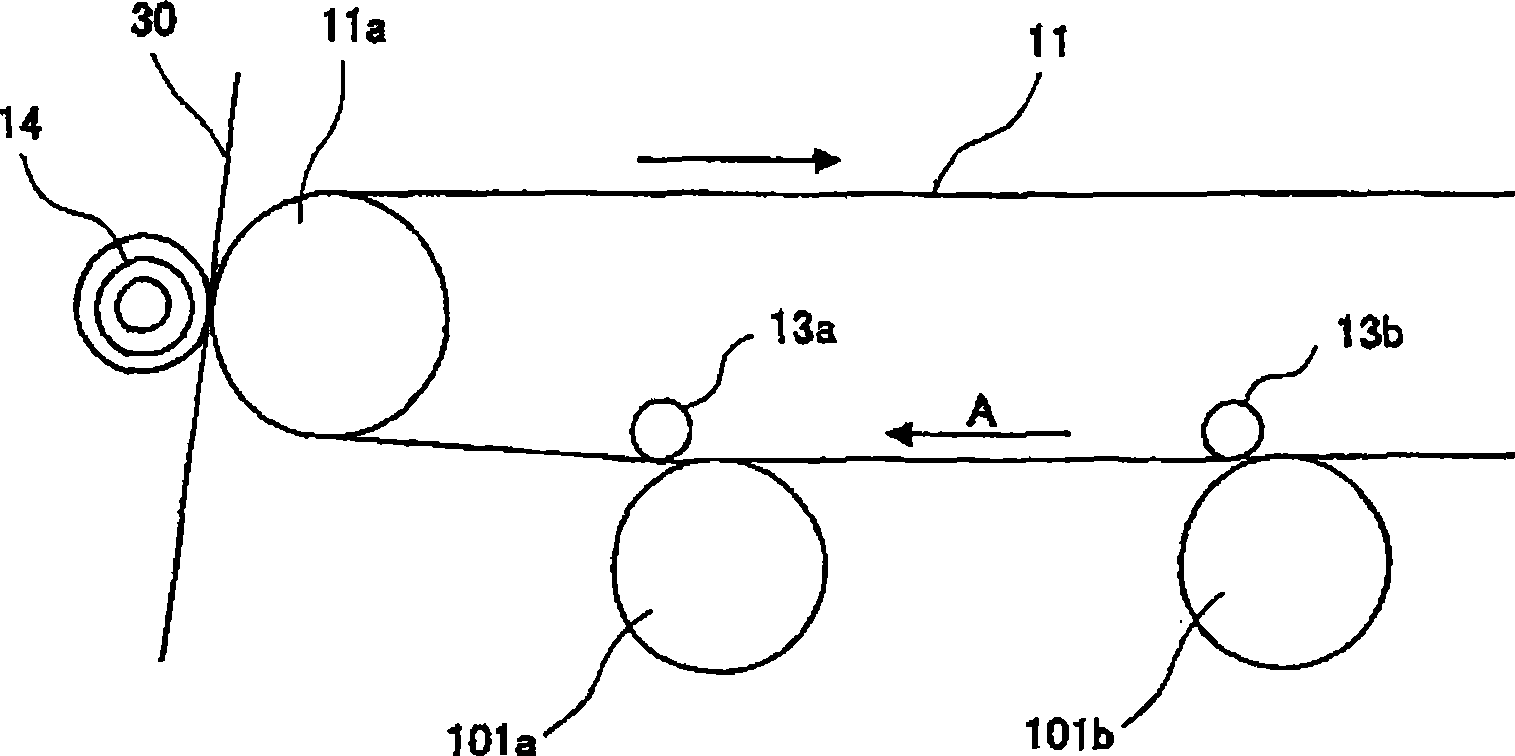

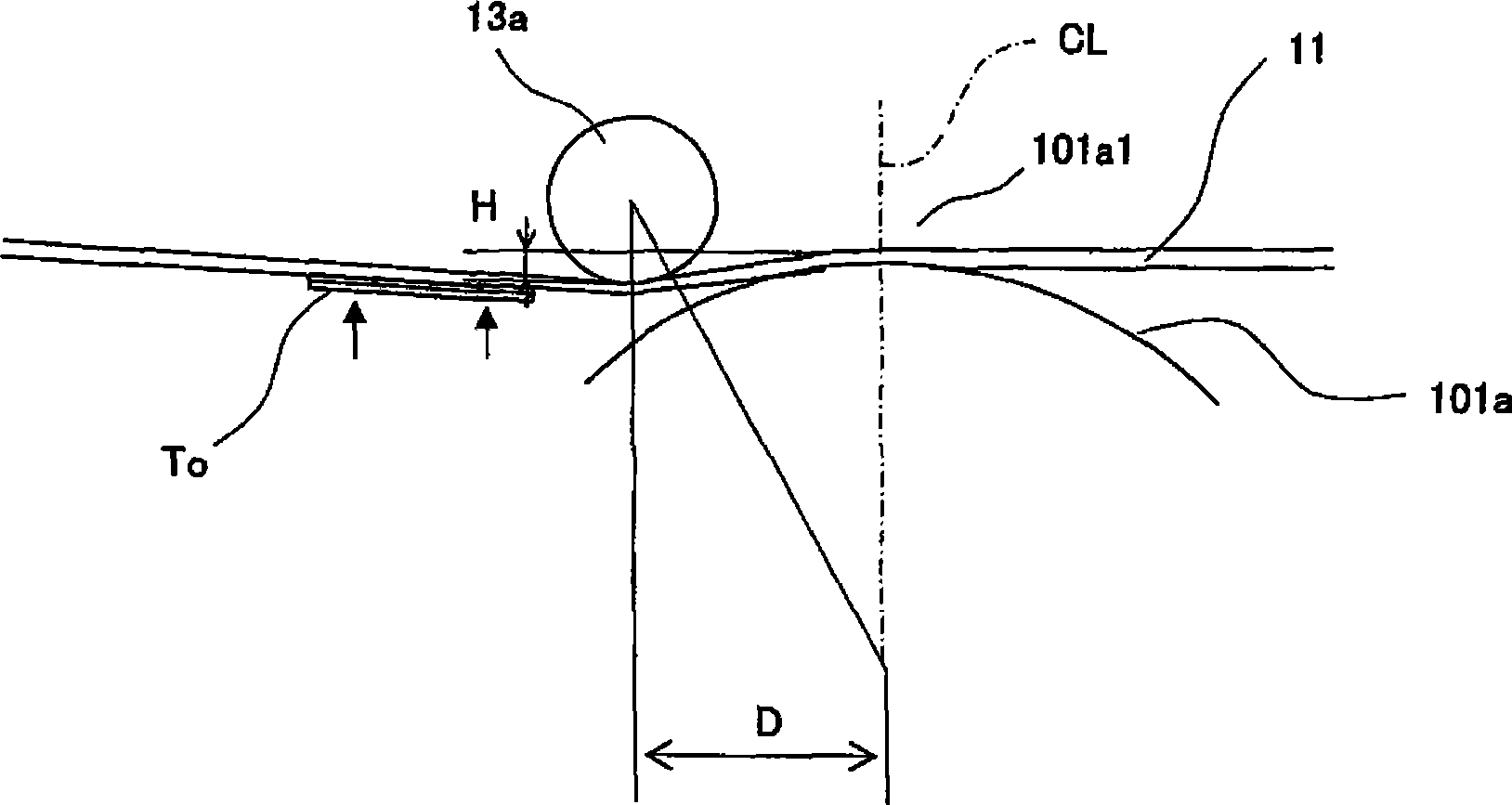

[0045] The image forming apparatus 100 of this embodiment, as shown in FIG. The toner image formed on it is carried; the primary transfer roller (transfer roller) 13, which presses the intermediate transfer belt 11 on the photosensitive drum 101, wherein the intermediate transfer belt 11 is driven along the surface of the photosensitive drum 101. The surface moves to transfer the toner image on the surface of the photosensitive drum 101 to the intermediate transfer belt 11 .

[0046] First, the overall configuration of image forming apparatus 100 according to the present embodiment will be described.

[0047] The image forming apparatus 100 forms multi-color and monochrome images on paper based on image data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com