Sealing device

A sealing device and side sealing technology, which is applied in engine sealing, bearing assembly, transportation and packaging, etc., to achieve the effects of improving sealing performance, stabilizing magnetic properties, and suppressing the increase in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Best Mode for Carrying Out the Invention

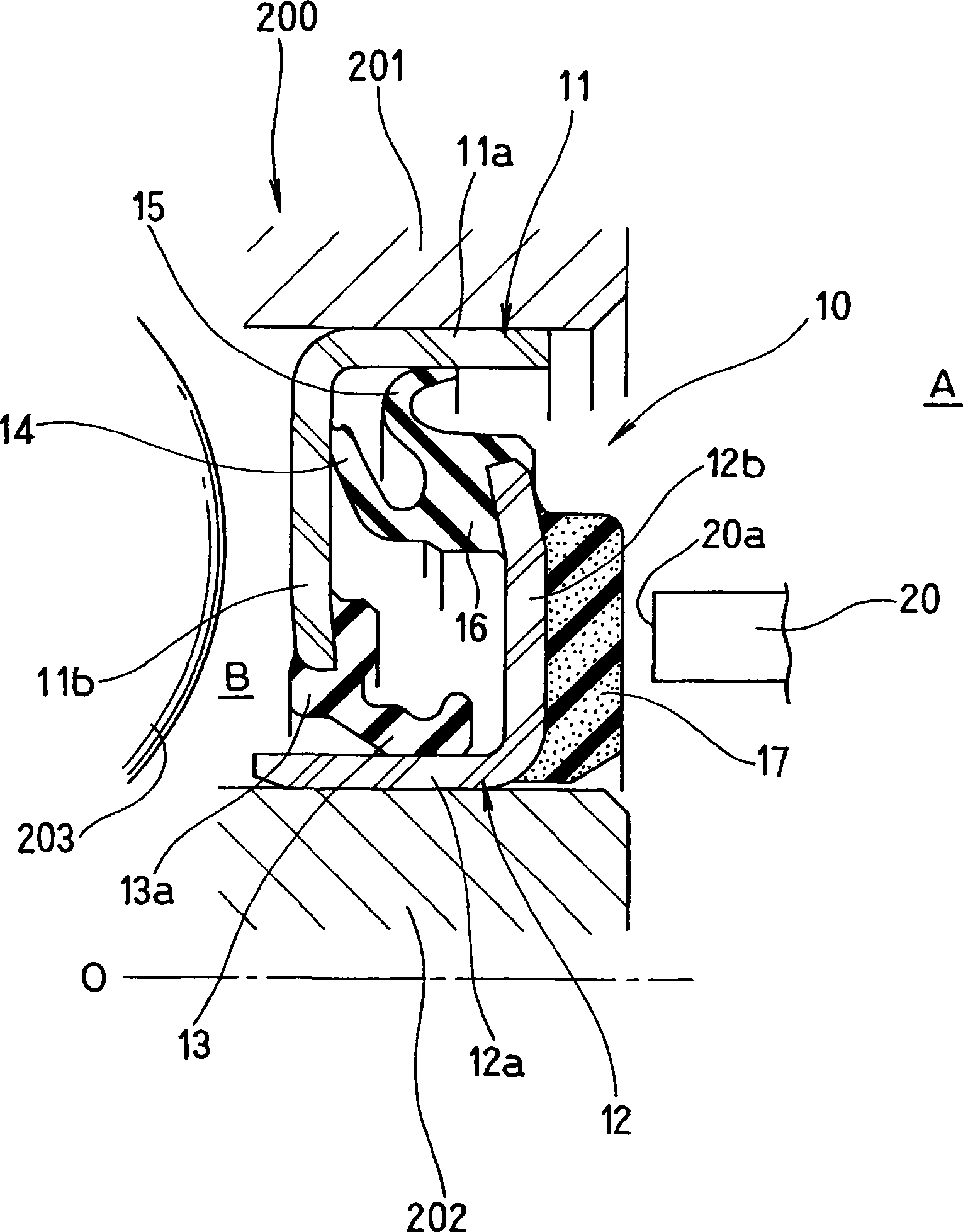

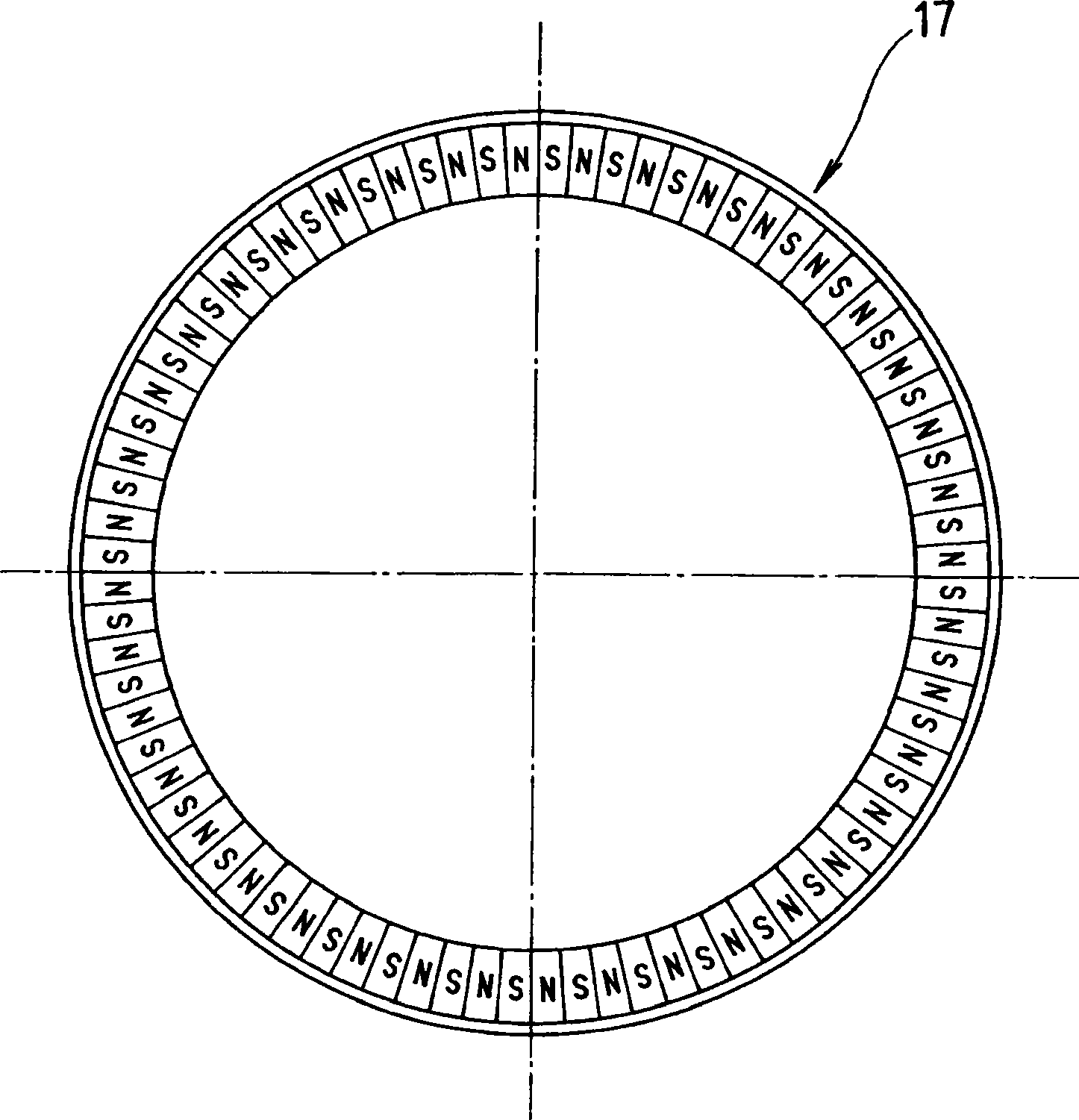

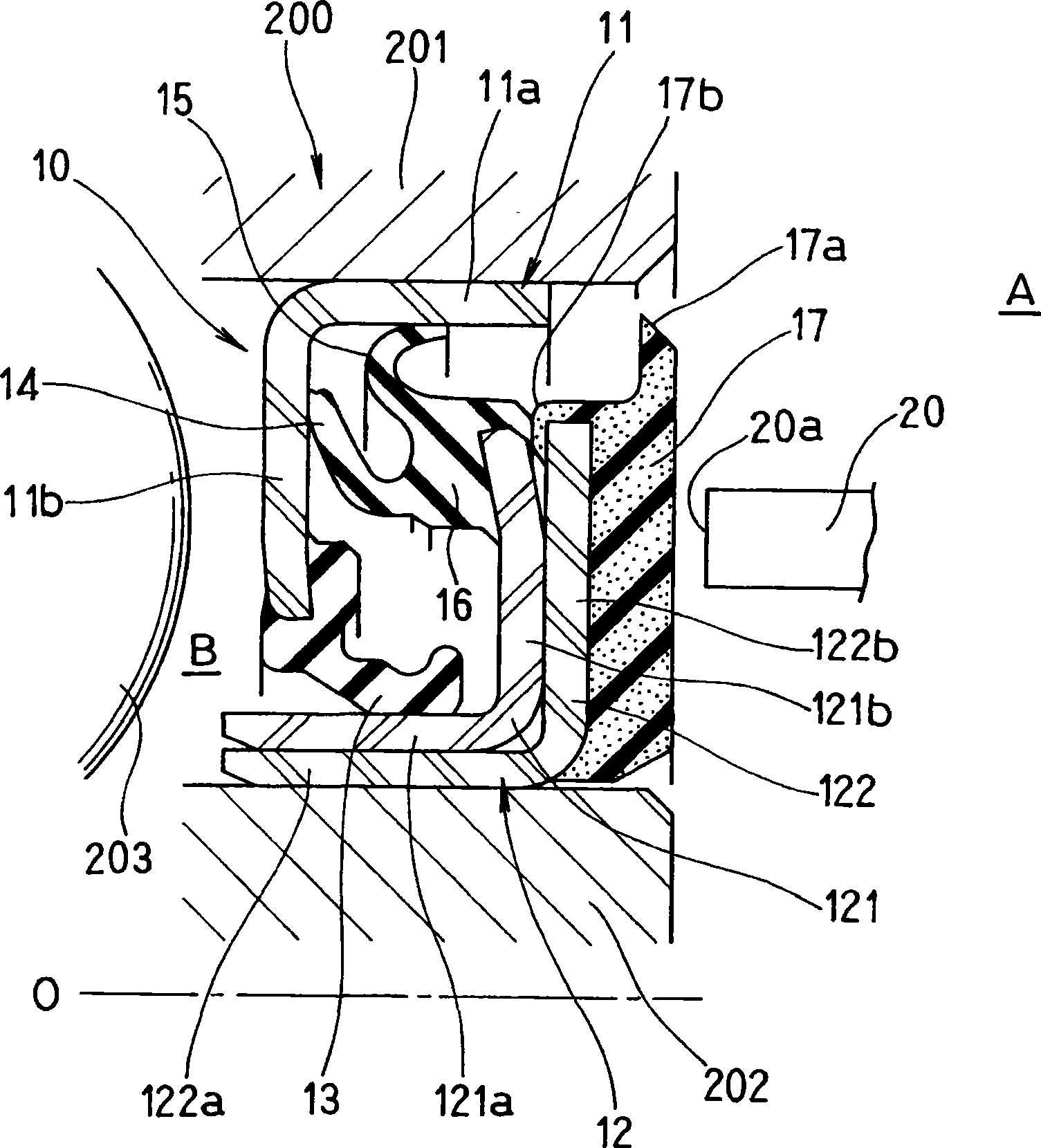

[0048] Preferred embodiments of the sealing device according to the present invention will be described below with reference to the drawings. figure 1 A cross-sectional view showing the sealing device according to the first embodiment of the present invention cut on a plane passing through the axis O, figure 2 It is an explanatory diagram showing an example of a pulsar ring magnetization pattern.

[0049] exist figure 1 In , reference numeral 200 is a bearing that rotatably supports a wheel in a vehicle suspension device, and a plurality of steel balls 203 are interposed between an outer wheel 201 and an inner wheel 202 arranged concentrically with the inner periphery thereof. Here, the outer ring 201 is non-rotating and corresponds to a stationary side member described in claim 1 , and the inner ring 202 rotates with an unshown shaft and corresponds to a rotating side member described in claim 1 .

[0050] The sealing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com