Electrical connector and method for manufacturing electrical connector

A technology for electrical connectors and manufacturing methods, which is applied to chemical instruments and methods, parts and connections of connecting devices, and can solve the problems of inability to obtain waterproof effects and increased costs, achieve simple assembly, and suppress the increase in manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0067] (Construction of electrical connector)

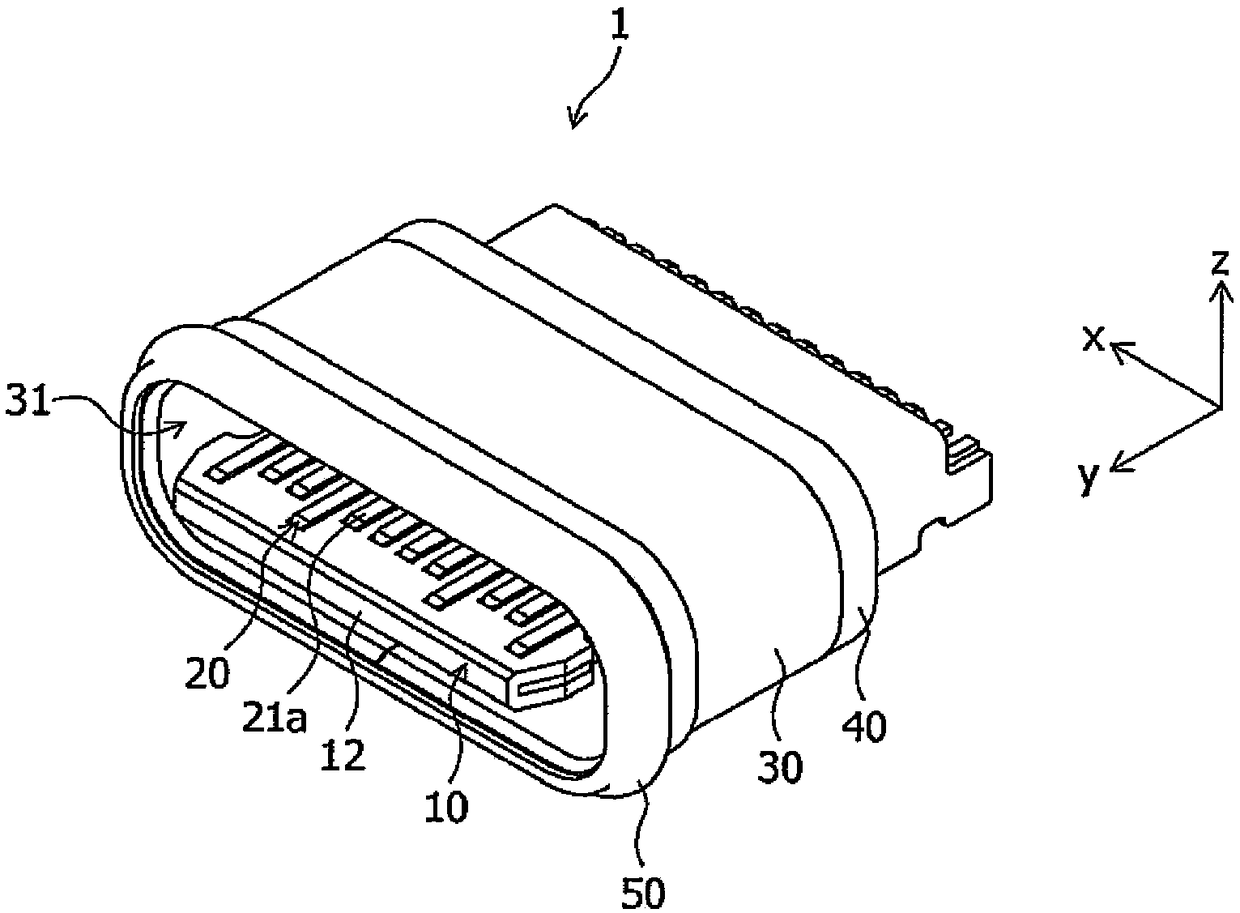

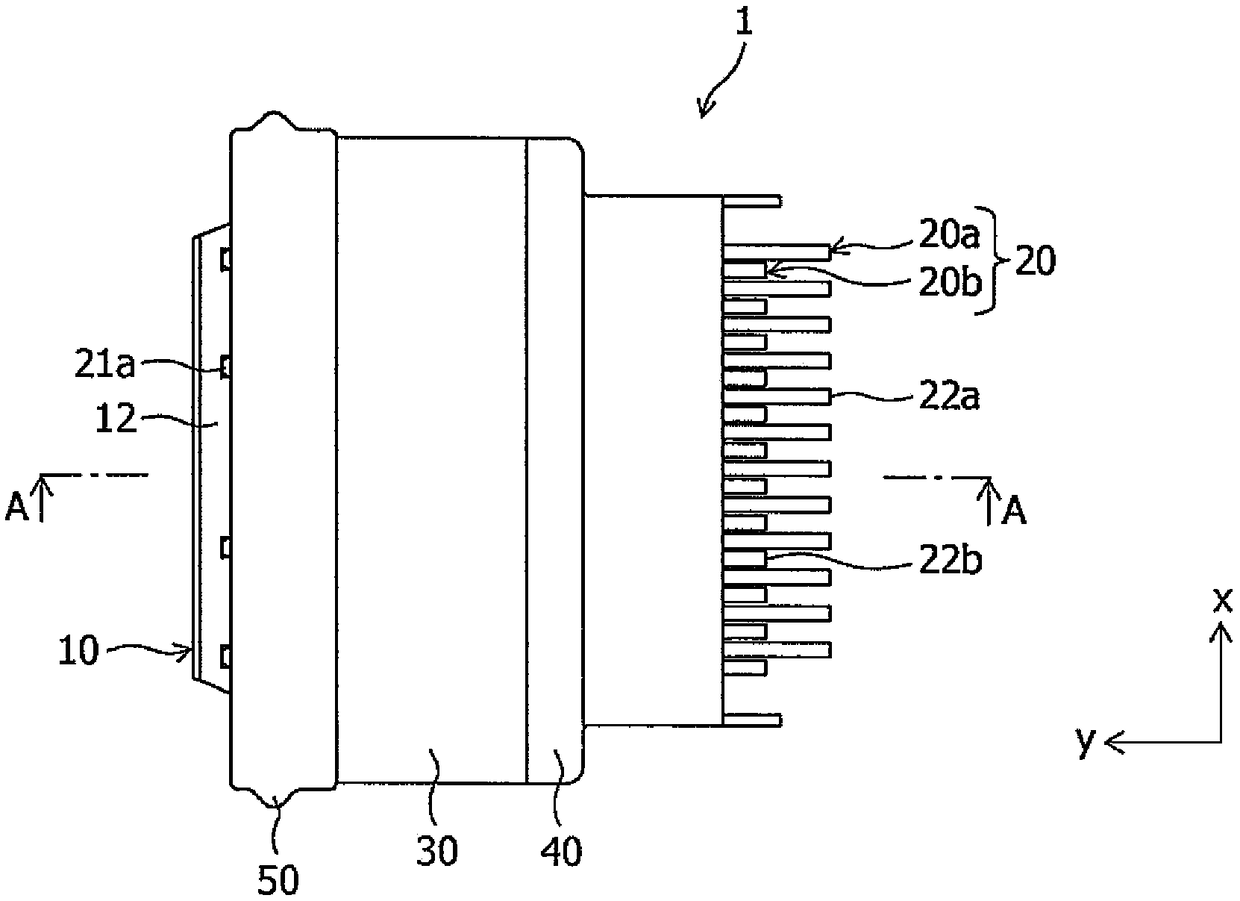

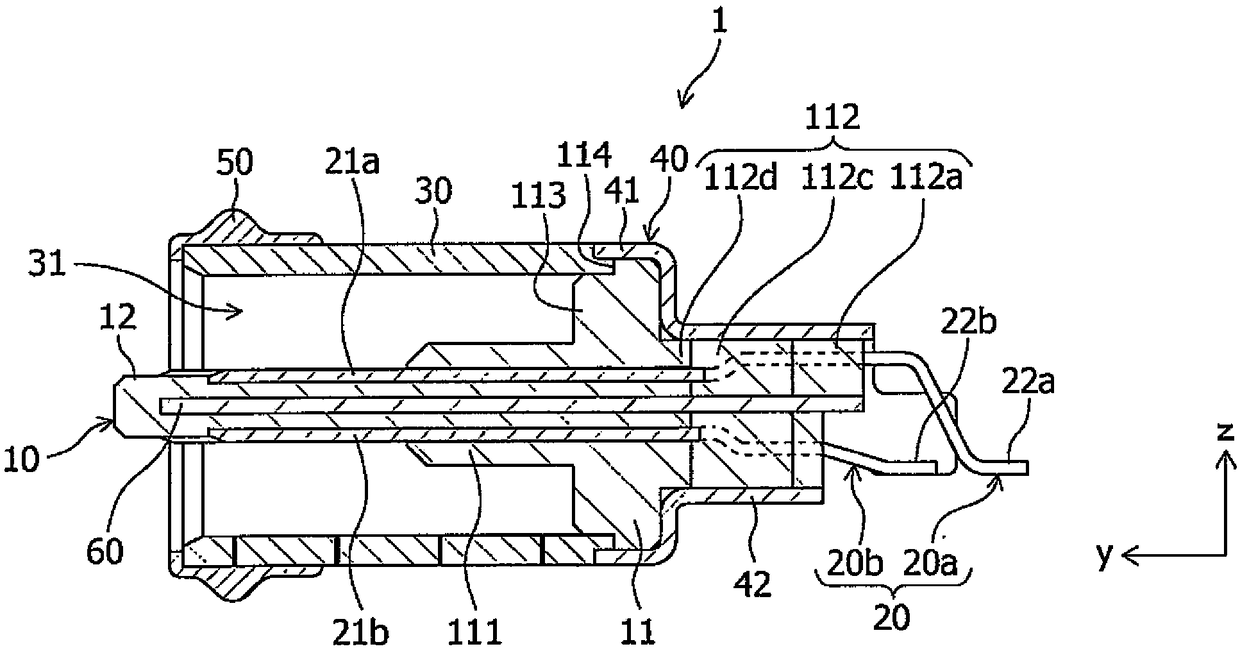

[0068] Regarding the structure of the electrical connector 1 according to the first embodiment of the present invention, while referring to Figure 1 ~ Figure 3 It will be described in detail below.

[0069] The electrical connector 1 of the present embodiment includes a housing 10 , a connector 20 , a front housing member 30 , a rear housing member 40 , an external waterproof member 50 , and a shielding plate 60 .

[0070] The case 10 is formed of an insulating material, and holds the connector 20 . The housing 10 contains a silane coupling agent along the outer peripheral surface of the connector 20 and in close contact with the connector 20 . The housing 10 does not contain a silane coupling agent at the rear end portion where the connector 20 protrudes rearward. Here, the silane coupling agent has a reactive group that can chemically combine with an inorganic material and a reactive group that can chemically combine with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com