Core holding device of rolled steel tube

A steel pipe and a combined technology, which is applied in the field of core holding devices for cross-rolling seamless steel pipes, can solve the problems of severe vibration of capillary and mandrel, inability to reliably guide capillary or mandrel, affecting the dimensional accuracy and surface quality of rolling process, etc. Achieve reliable guidance and solve the effect of anti-shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

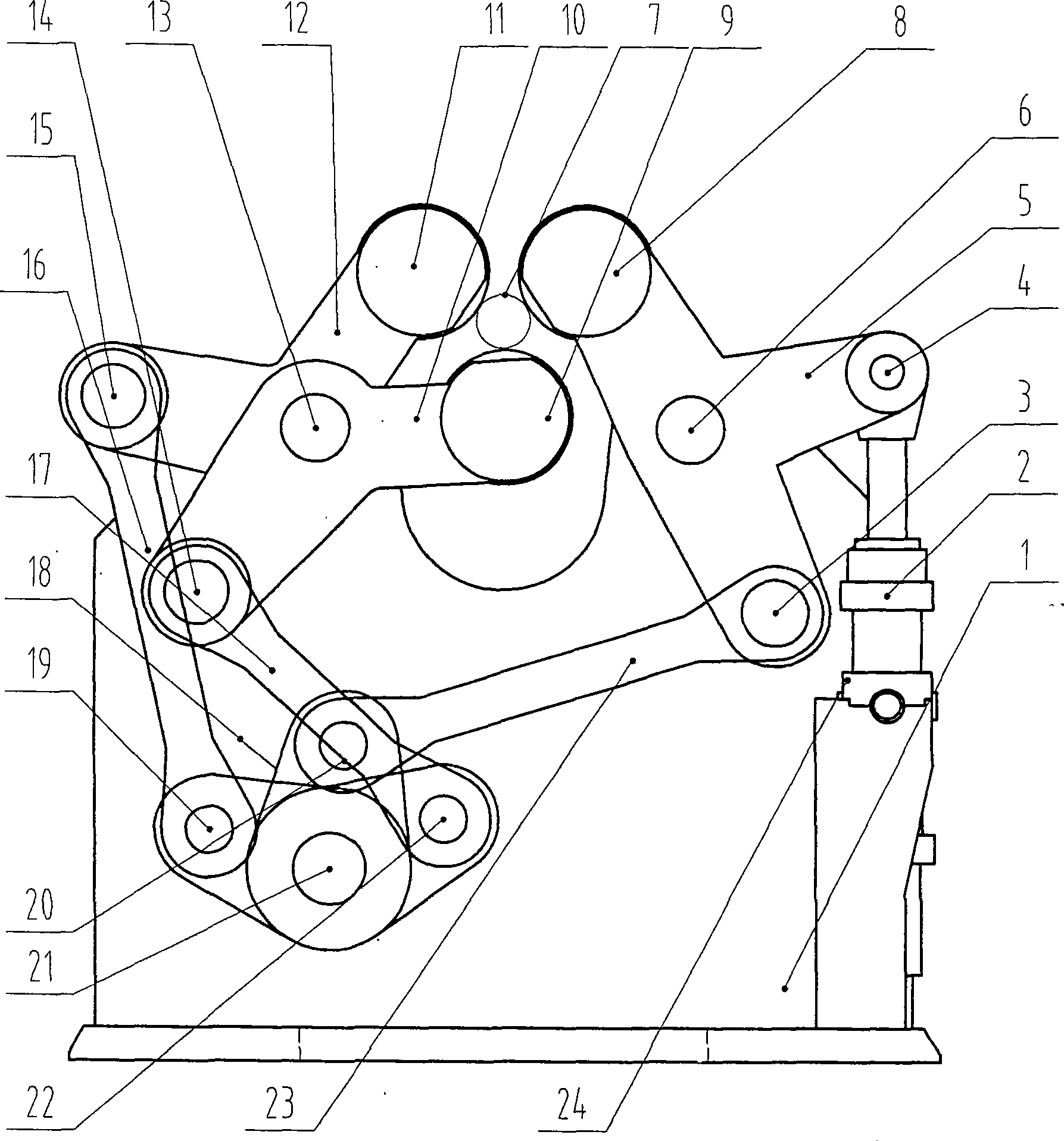

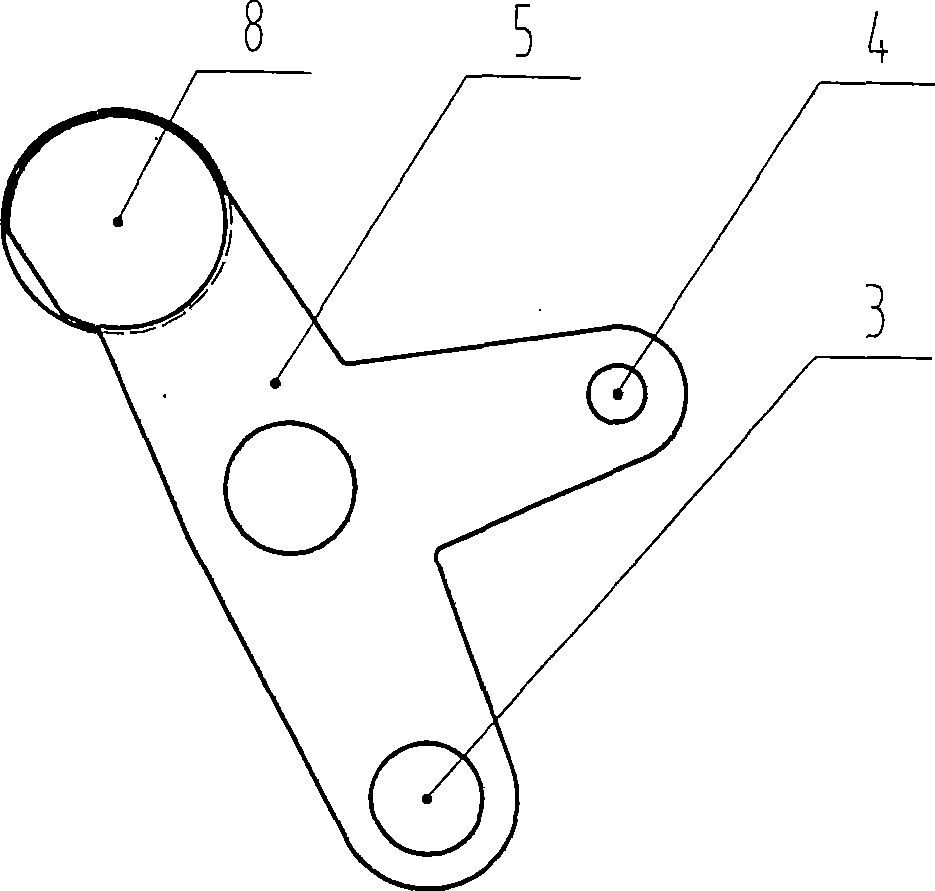

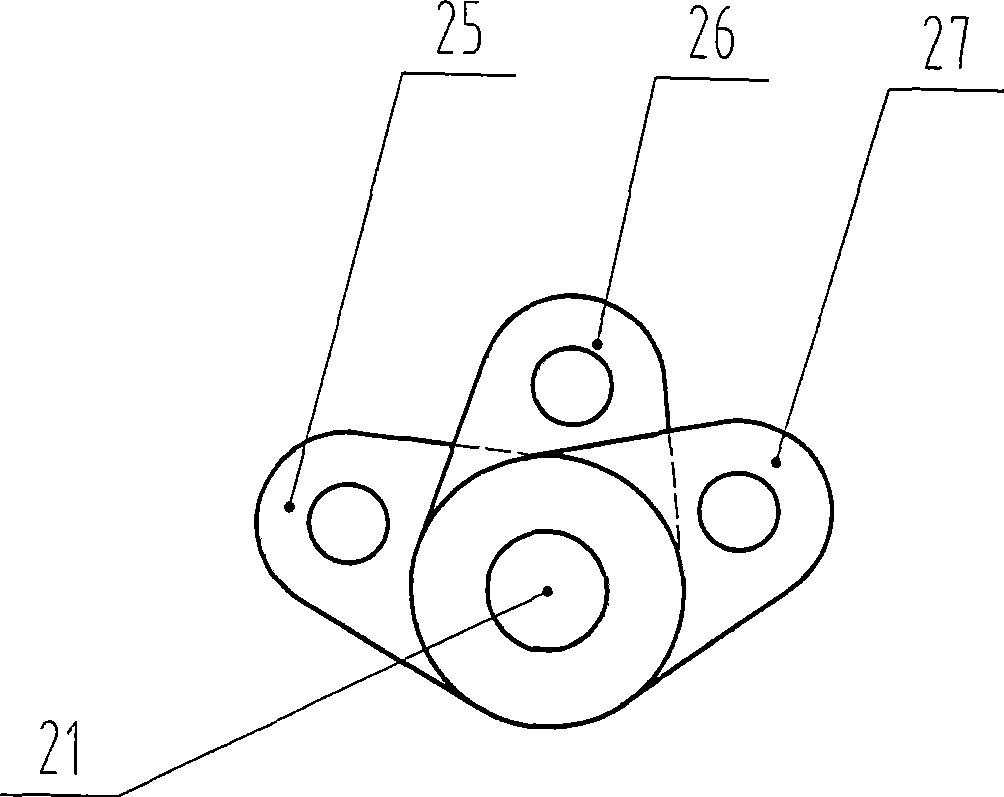

[0013] A core-holding device for rolling steel pipes, comprising a frame 1, a T-shaped lever 5, a first V-shaped lever 10, a second V-shaped lever 12, a multi-head lever 18, a first connecting rod 17, a second connecting rod 16, The third connecting rod 23 and the stroke-adjustable hydraulic cylinder or cylinder 2, the T-shaped lever 5 rotates around the fixed mandrel A6 provided on it and is arranged on the obliquely upper side of the frame 1, the first The V-shaped lever 10 and the second V-shaped lever 12 rotate around the fixed mandrel installed in the middle, these two V-shaped levers are arranged on the other side above the oblique top of the frame 1, and make the first V-shaped The V-shaped mouth of the lever 10 is facing opposite to the V-shaped mouth of the second V-shaped lever 12. The multi-headed lever 18 is rotated around the fixed mandrel C21 and is arranged obliquely below the frame 1. The first of the multi-headed lever 18 The hinge point 25, the second hinge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com