Connection method of PE plastic tube and PE steel wire mesh frame plastic composite tube

A connection method and steel wire mesh technology, which is applied in the connection between PE plastic pipes and PE steel mesh skeleton plastic composite pipes, and in the field of connection between pipes, can solve the problems of complicated connection, difficult to be widely used, and high requirements for installation environment Achieve the effects of high safety performance, easy promotion, and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further illustrated below through specific examples.

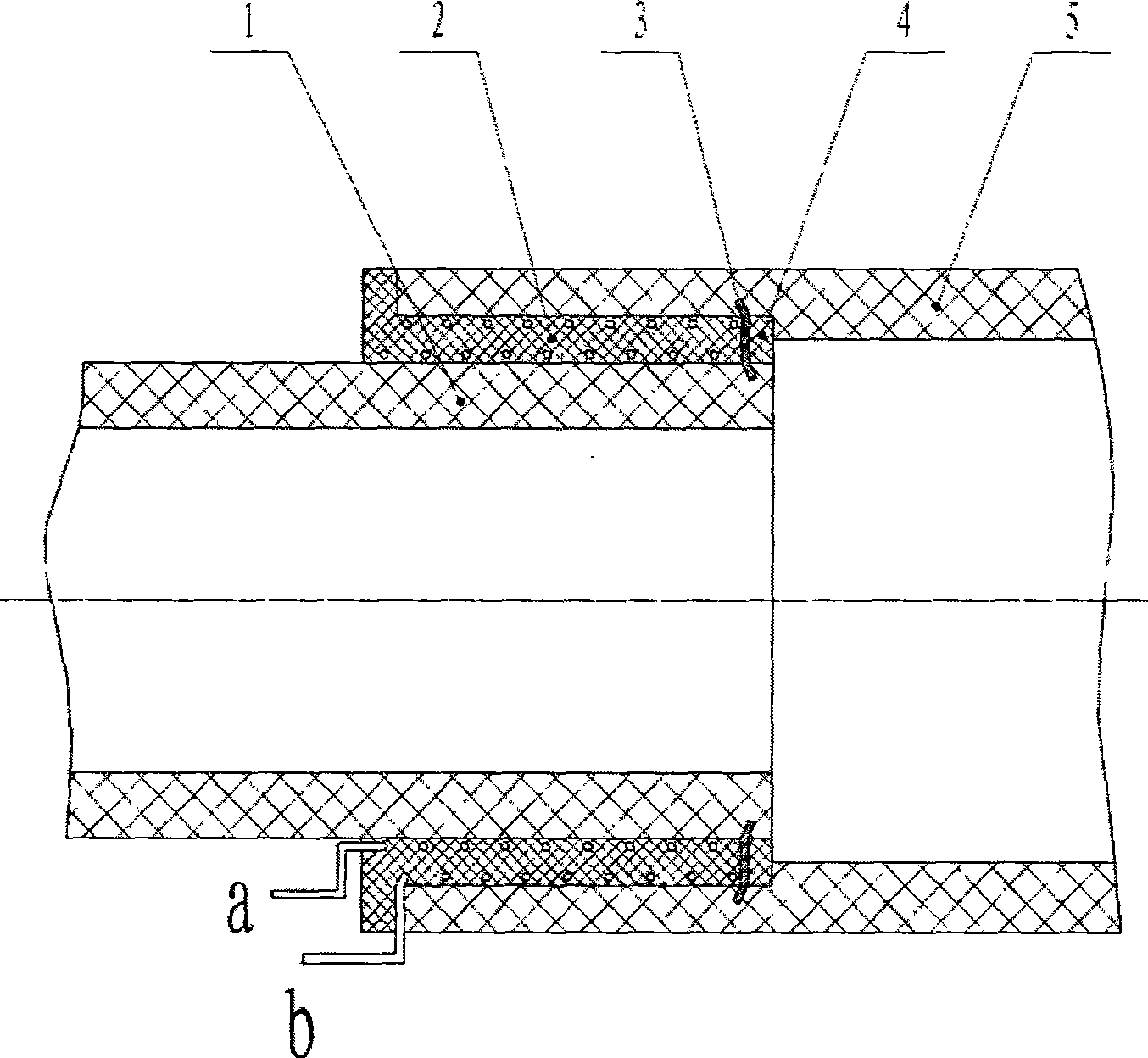

[0020] Further details according to the attached drawings:

[0021] The steps to connect the pipeline are as follows:

[0022] (1) Insert the PE steel wire mesh skeleton plastic composite pipe 1 into the PE electric heating sleeve 2, and connect and fix it through the metal retaining ring 3;

[0023] (2) Fluorine rubber 4 is lined at the junction of the pipes;

[0024] (3) Insert the PE plastic pipe 5 into place from the other end of the PE electric heating sleeve 2, and install the composite pipe 1 in place by means of a tensioner;

[0025] (4) Make the two ends a and b of the resistance wire of the electric melting core of the PE electric heating melting sleeve 2 energized to generate heat fusion, and realize the connection between the PE steel mesh skeleton plastic composite pipe 1 and the PE plastic pipe 5 . The connected pipeline structure is as follows fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com