Guide rail for container ship and erection method thereof

A container ship and guide rail technology, applied in the field of guide rails, can solve problems such as low efficiency and difficult control accuracy, and achieve the effect of improving erection efficiency and convenient control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

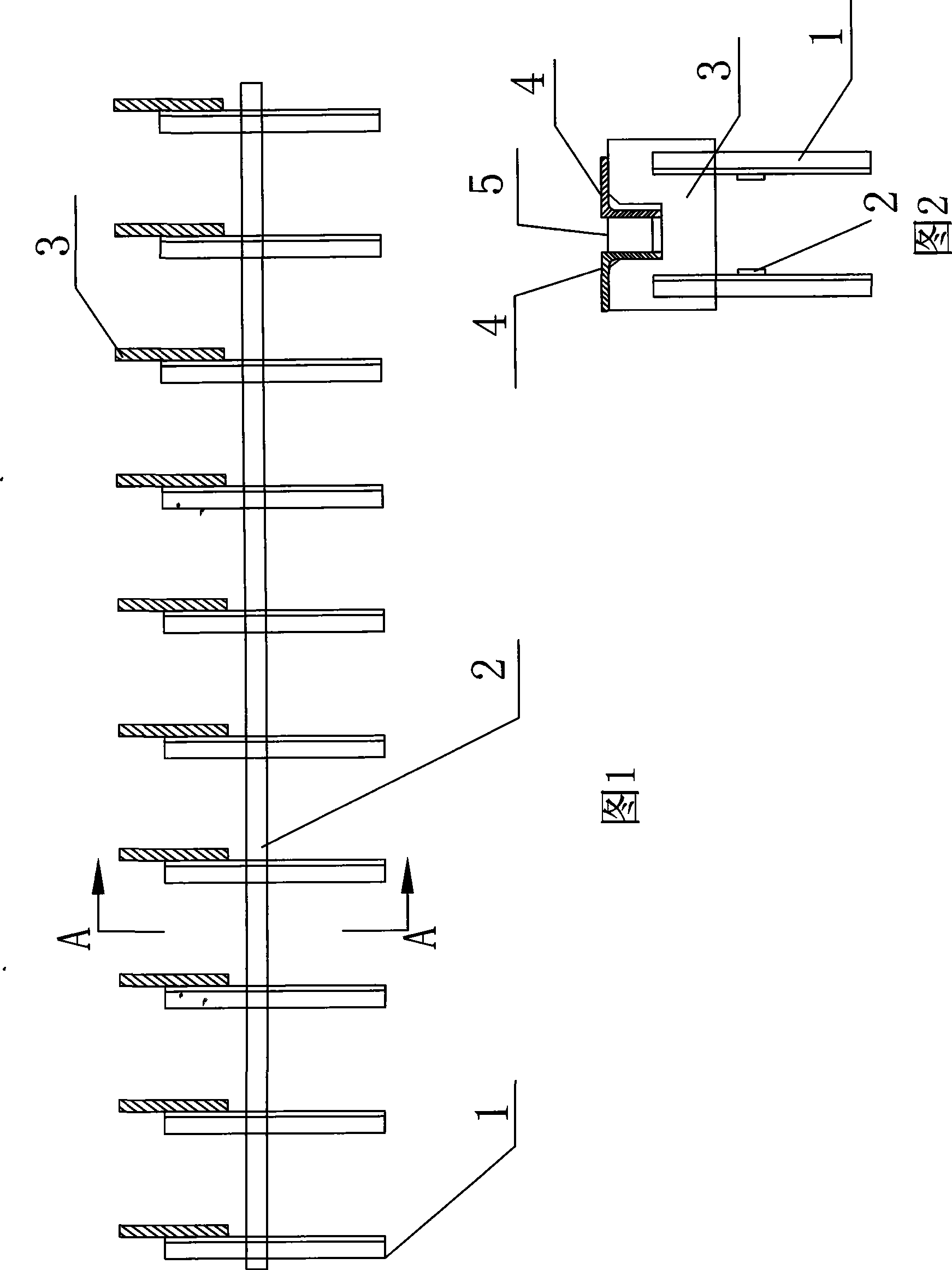

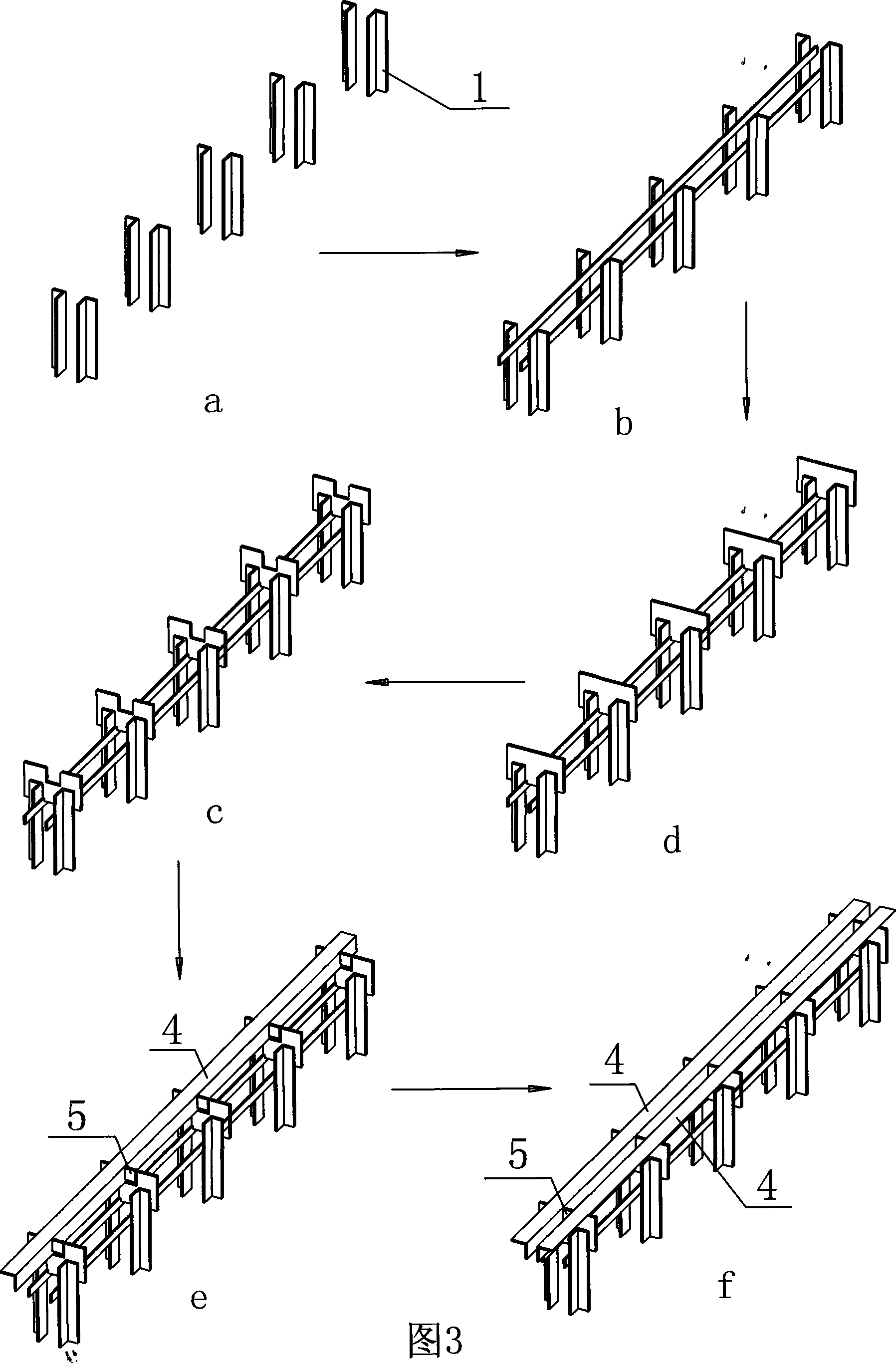

[0018] The guide rail of the present invention is described with reference to Fig. 1 and Fig. 2 . Wherein, the guide rail for a container ship of the present invention includes two rows of parallel and opposed leg angle steels 1, and each row of leg angle steels 1 is upright and arranged at intervals. The two columns of leg angle steels correspond one-to-one, and a plane of each leg angle steel 1 is set as the inner surface. Wherein, the angle steel used in the present invention is a steel material in which two steel planes are at right angles to each other. The angle steel can be equivalently replaced by other structures such as bars as required. By referring to the flow process of Fig. 3 guide rail erection, it can be seen that the inner surface of each row of leg angle steel 1 of the present invention is welded and fixed with an integral connection flat iron 2 (so-called inner surface refers to the opposite surface between two guide rails). In addition, the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com