Wireless sensing type rectifying system of rail gantry crane

A technology of wireless sensing nodes and gantry cranes, which is applied in the direction of walking bridge cranes, load suspension components, safety devices, etc., can solve the problems of transmission ratio changes, position signal accuracy decline, large errors, etc., and achieve high deviation correction accuracy , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

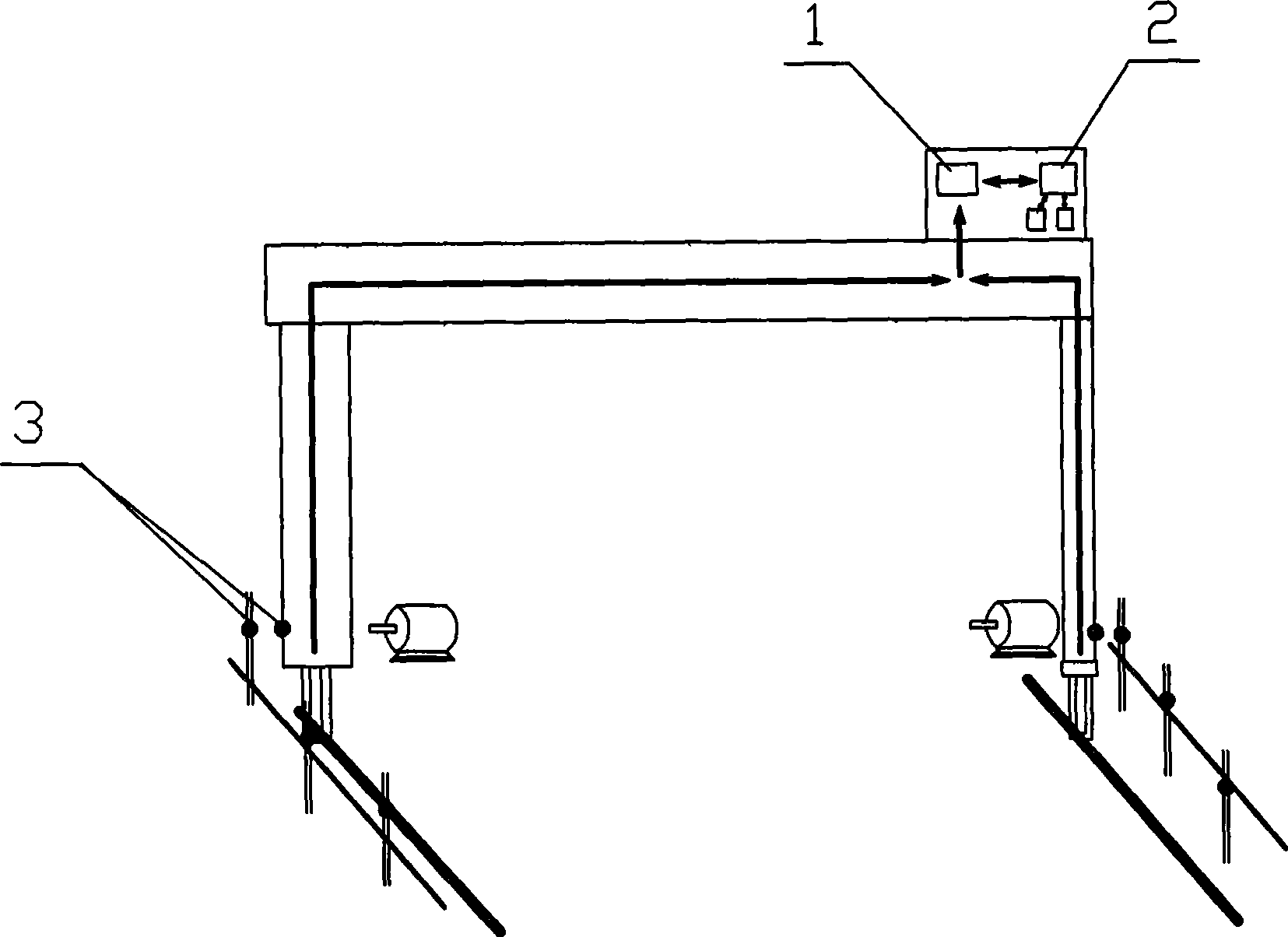

[0011] like figure 1 As shown in the figure, a wireless sensor type deviation correction system for a rail gantry crane, which has a deviation correction processor 1 and a programmable logic controller 2 installed in the electrical room of the gantry crane, and also has rigid legs, flexible legs and rail guardrails respectively arranged on the gantry crane. The sensor nodes 3 on the sensor node 3 for collecting signals, each sensor node 3 is in the same wireless sensor network.

[0012] The wireless sensing nodes 3 on the rail guardrail of the gantry crane are arranged at intervals by the guardrails, one for each railing, and the distance between two adjacent railings is 20-30m.

[0013] By installing wireless sensor nodes 3 on the rigid legs, flexible legs and rail barriers of the gantry crane, and using the self-positioning function of the wireless sensor network nodes, the positions of the rigid legs and flexible legs on the track of the gantry crane can be directly measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com