Continuous production method of foam filling panel

A production device and foam filling technology, which is applied in the field of continuous production equipment for foam filled boards, can solve problems such as deformation of the car wall or the outer wall of the door panel, and achieve a high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

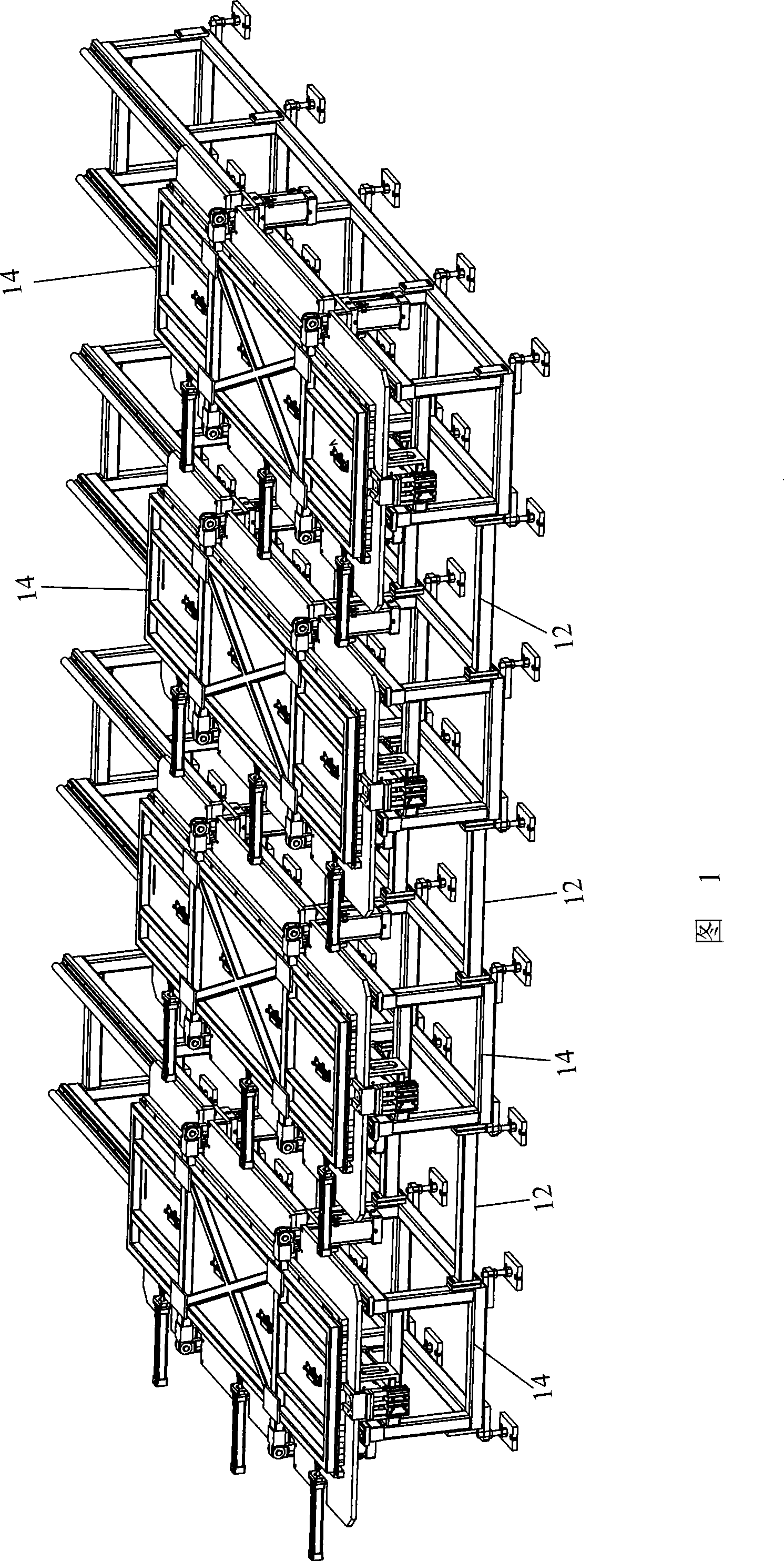

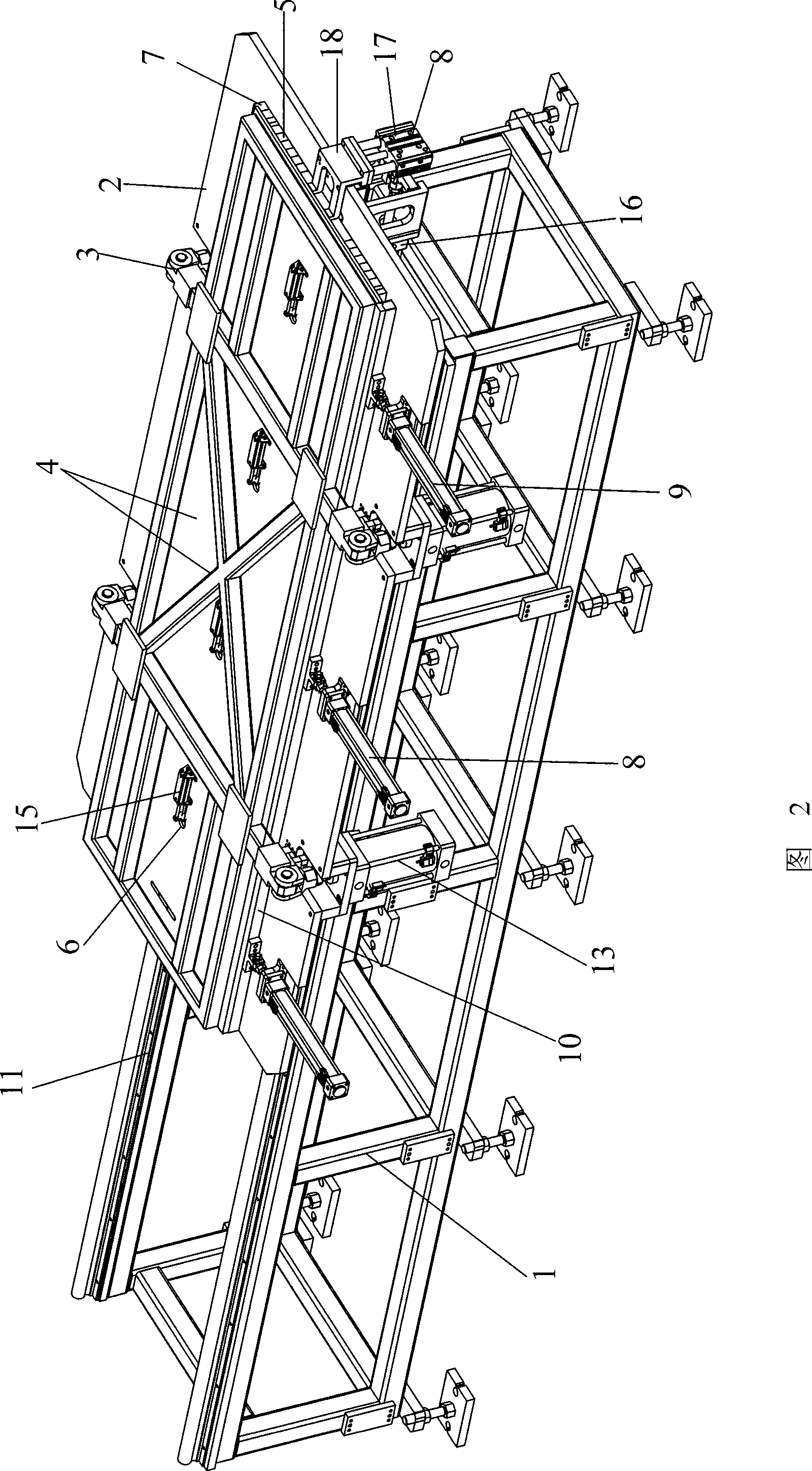

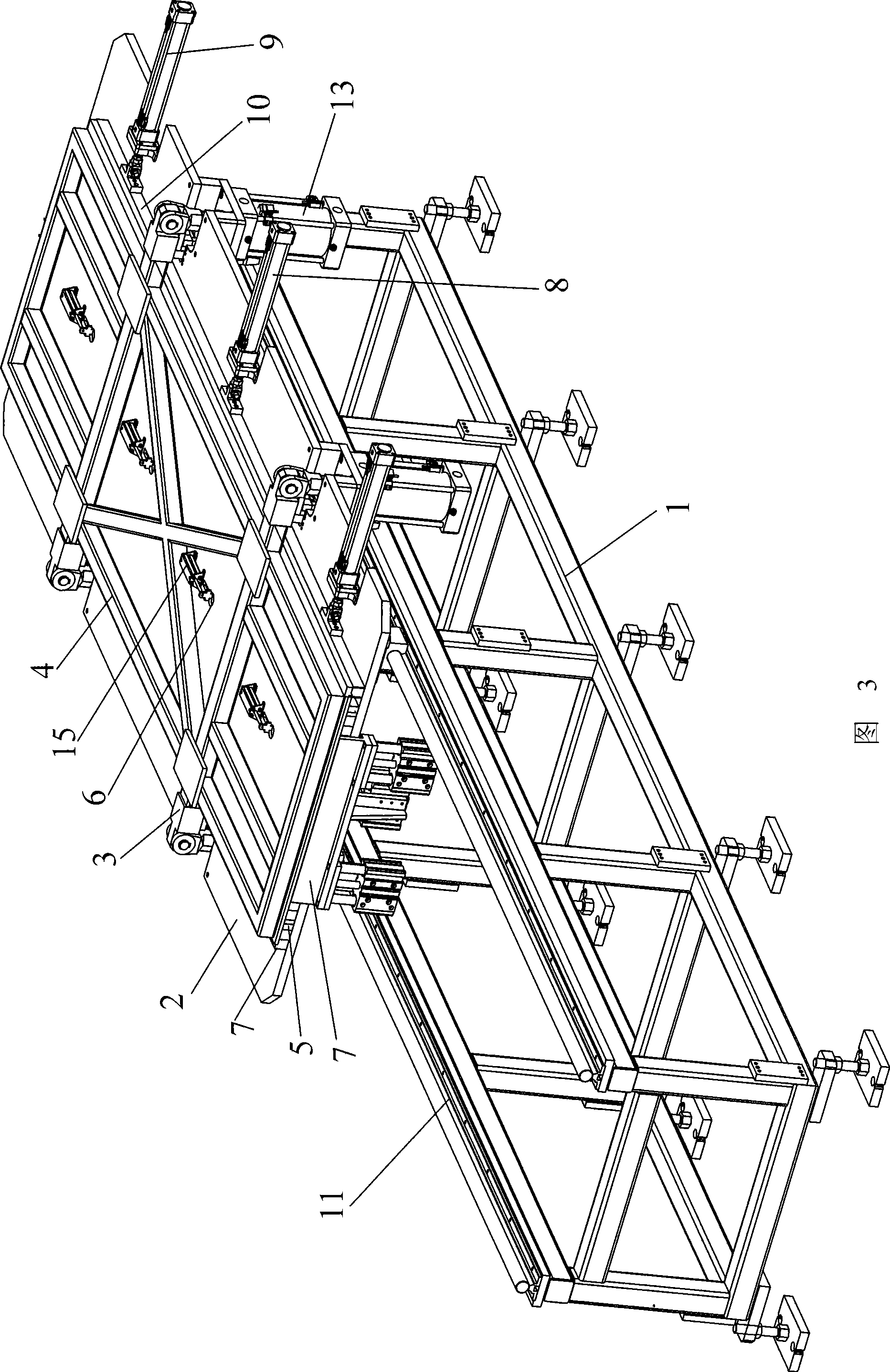

[0023] Embodiment: as shown in Fig. 1 to Fig. 3, a kind of continuous production device of foamed filling board comprises at least one individual workbench 14, and each individual workbench 14 comprises frame 1, is used for placing on frame 1 The work surface 2 of the workpiece 5 to be processed, the work surface 2 is fixed with a press plate lifting frame 3, the lifting part of the pressure plate lifting frame 3 is connected with a pressure plate 4 that can be lifted up and down above the work surface 2, and the pressure plate 4 is provided with There is an injection hole 6 corresponding to the foam filling hole on the workpiece 5 to be processed, and the working table 2 is provided with limiting fixing parts around the thickness direction of the workpiece 5 to be processed.

[0024] There are several injection holes 6, and guide rails 11 are provided on the frame 1 along the distribution direction of several injection holes 6, and the bottom of the work surface 2 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com