Improved ultra-high pressure stopped foot pedal control valve

A control valve, ultra-high pressure technology, applied in the direction of valve details, valve devices, functional valve types, etc., can solve the problems of small application range, inadequate sealing, waste of water resources, etc., to achieve wide application range, good sealing performance, and energy saving The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

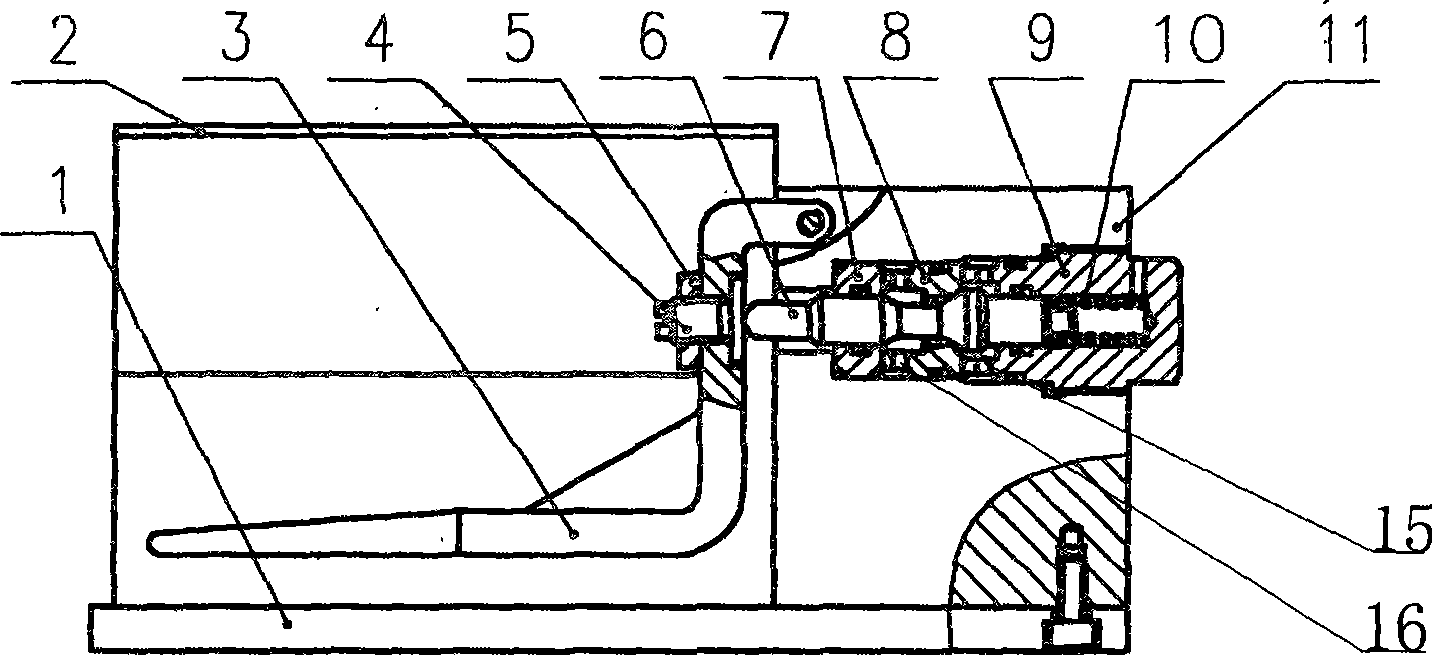

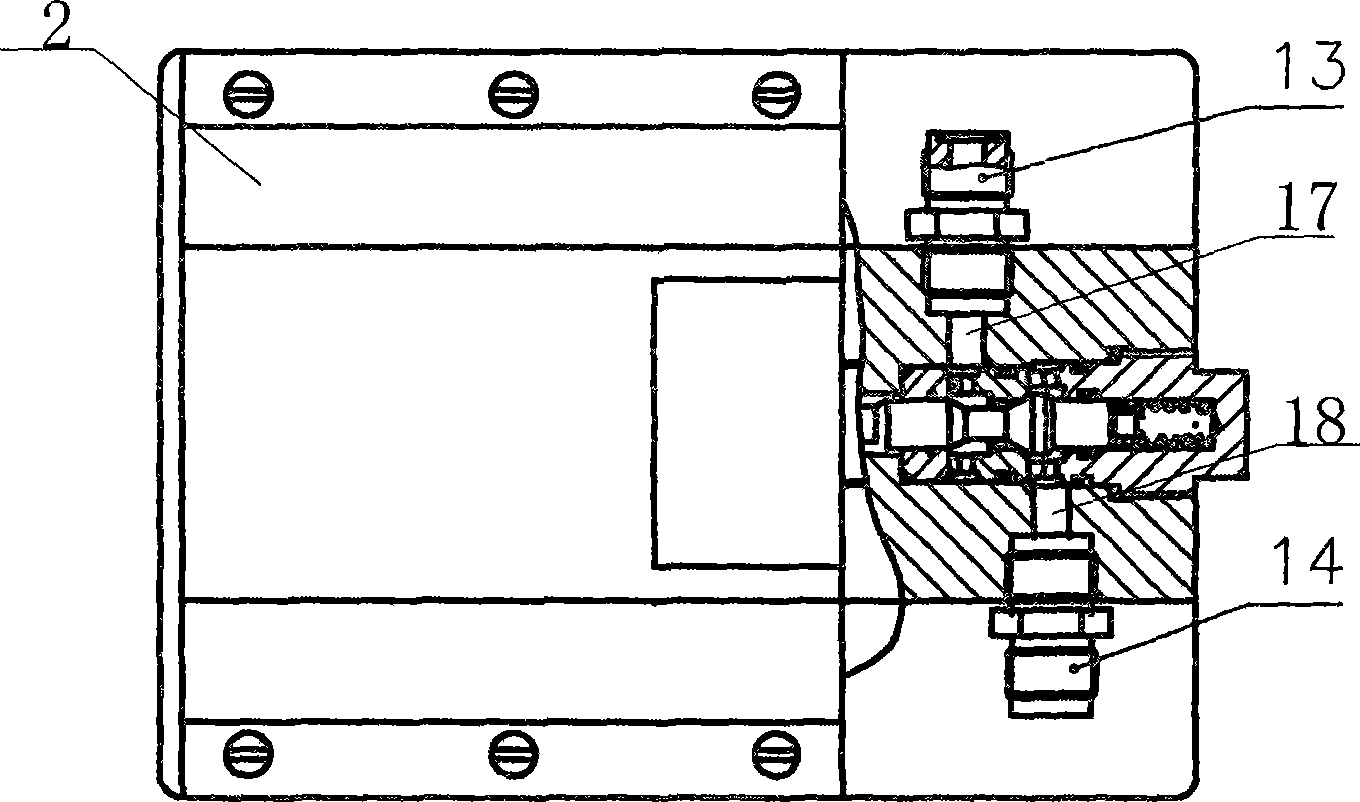

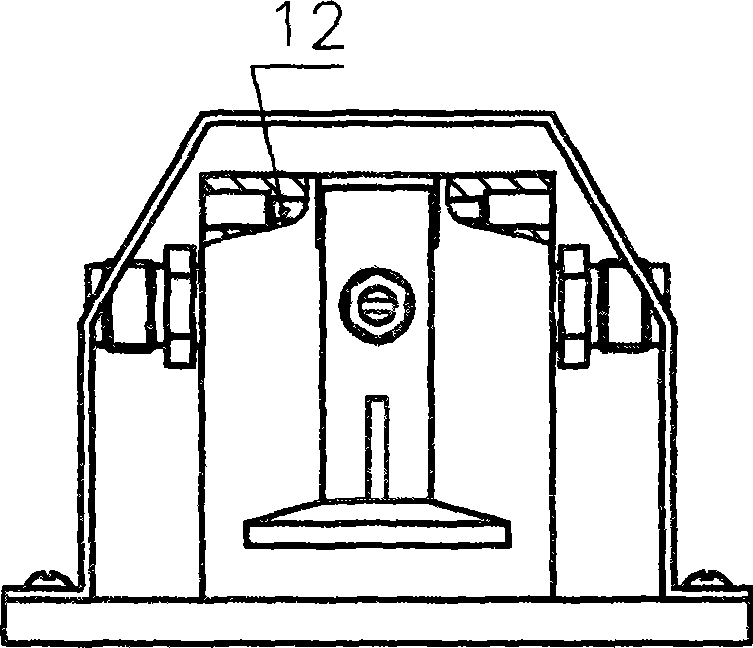

[0010] See figure 1 , figure 2 , image 3 , the present invention includes a bottom plate 1, a shield 2, a pedal 3, a valve body 6, a liquid outlet 13, and a liquid inlet 14. A valve body 11 is installed on the front of the bottom plate 1, and the pedal 3 is installed on the valve body through two cylindrical pins 12. 11. The pedal 3 is covered with a shield 2, the shield 2 is installed on the bottom plate 1, the valve core 6 is installed inside the valve body 11, the pedal 3 is directly facing the valve core 6, and an adjustment device is installed at the end of the valve body 11. The guide sleeve 7 and the valve seat 8 are installed in turn, the guide sleeve 7 is set on the valve core 6, the valve seat 8 is pressed and fixed on the valve body 11 by the screw sleeve 9, and a spring is pressed between the other end of the valve core 6 and the screw sleeve 9 10. The valve body 11 has a liquid inlet channel 18 and a liquid outlet channel 17. The valve seat 8 has a water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com