Insulation voltage equalizing ball used for super-high or extra-high voltage transformer and production process thereof

A manufacturing method and technology of equalizing balls, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., to achieve the effects of shortening insulation distance, prolonging working life, and improving the use of field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

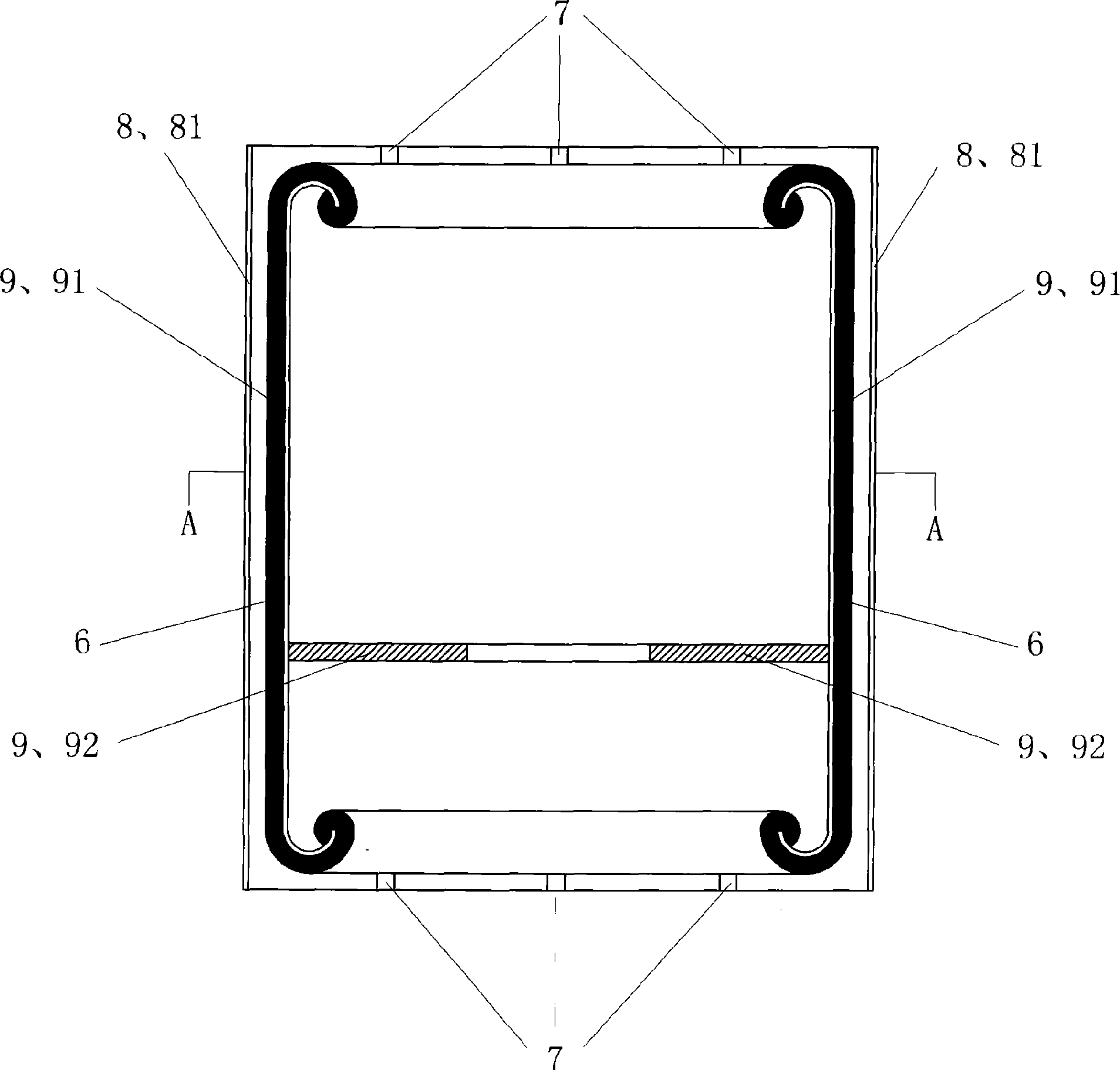

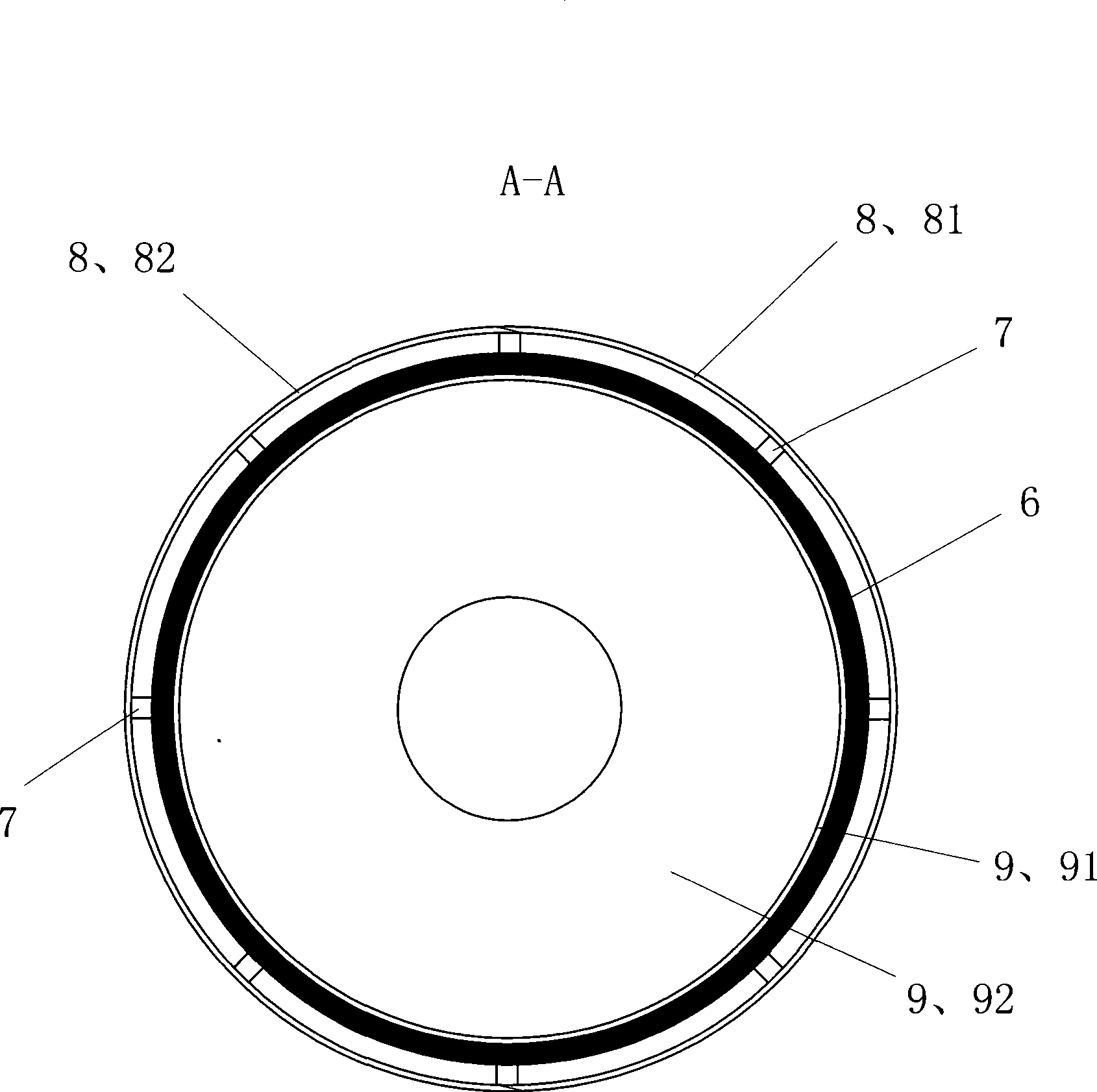

[0017] See figure 1 and figure 2 , the insulating equalizing ball used for ultra-high voltage or ultra-high voltage transformers of the present invention has a pure insulating paper cover shell 6, a pure insulating paper stay 7, a pure insulating paper cylinder 8 and an equalizing ball 9.

[0018]The pressure equalizing ball 9 has a hollow metal sphere 91. The metal sphere 91 has two openings, one is the wire outlet and the other is the wire inlet. Shape, the pressure equalizing ball 9 also has a ring-shaped flange 92 made of metal, the flange 92 is located in the metal sphere 91 and fixed with the inner wall of the metal sphere 91 .

[0019] The pure insulating paper covering shell 6 is tightly covered on the outer wall of the metal sphere 91 , and the pure insulating paper cylinder 8 is sleeved outside the pure insulating paper covering shell 6 . There are 8 pure insulating paper stays 7 of the present embodiment. And each pure insulating paper stay 7 is arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com