Insulation voltage equalizing tube used for super-high or extra-high voltage transformer and production process thereof

A manufacturing method and technology of a pressure equalizing tube, which are applied in the directions of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of inability to meet the technical requirements of ultra-high voltage and ultra-high voltage transformers, improve the use field strength, improve Reliability, the effect of eliminating the hidden danger of partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

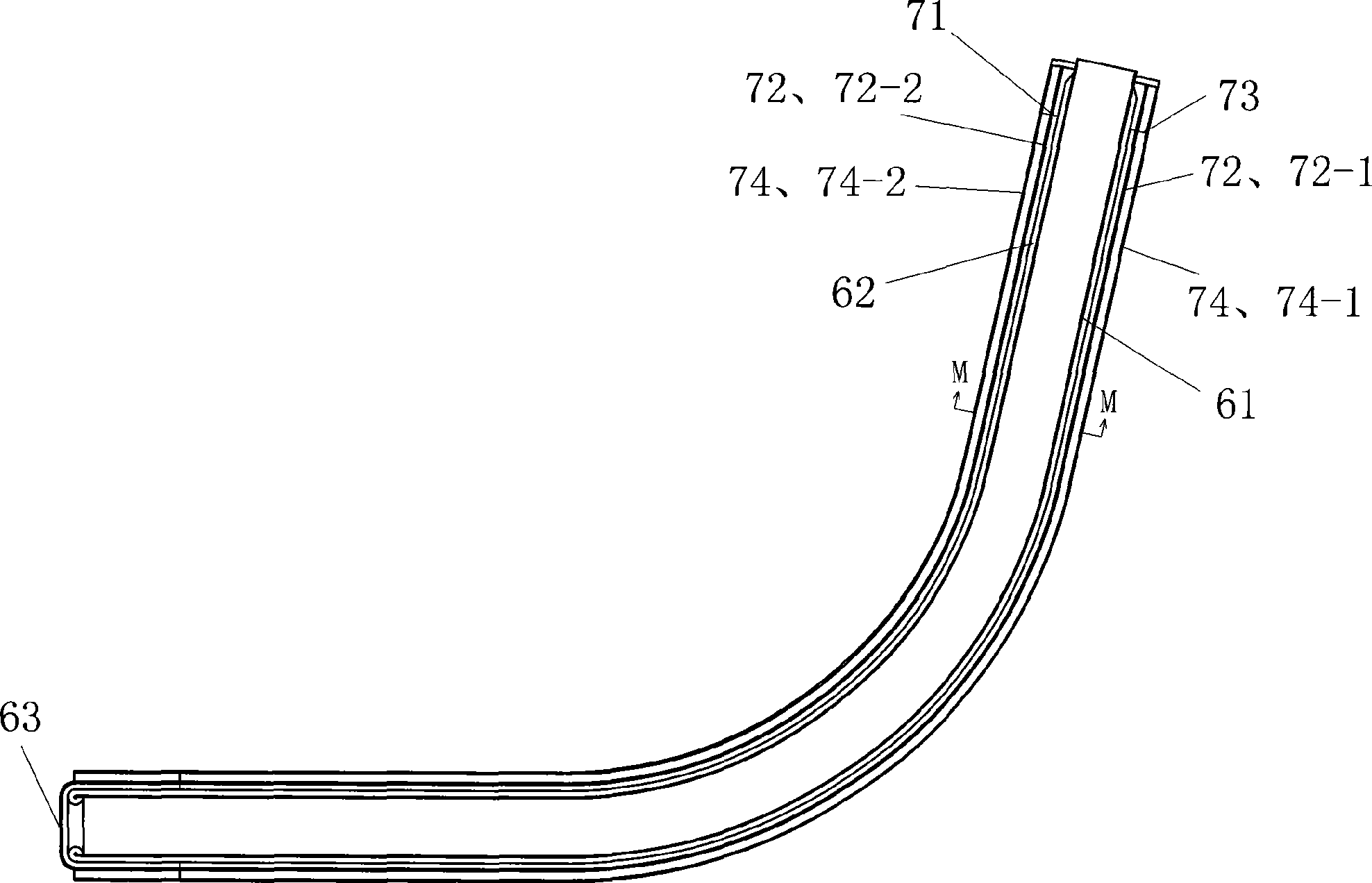

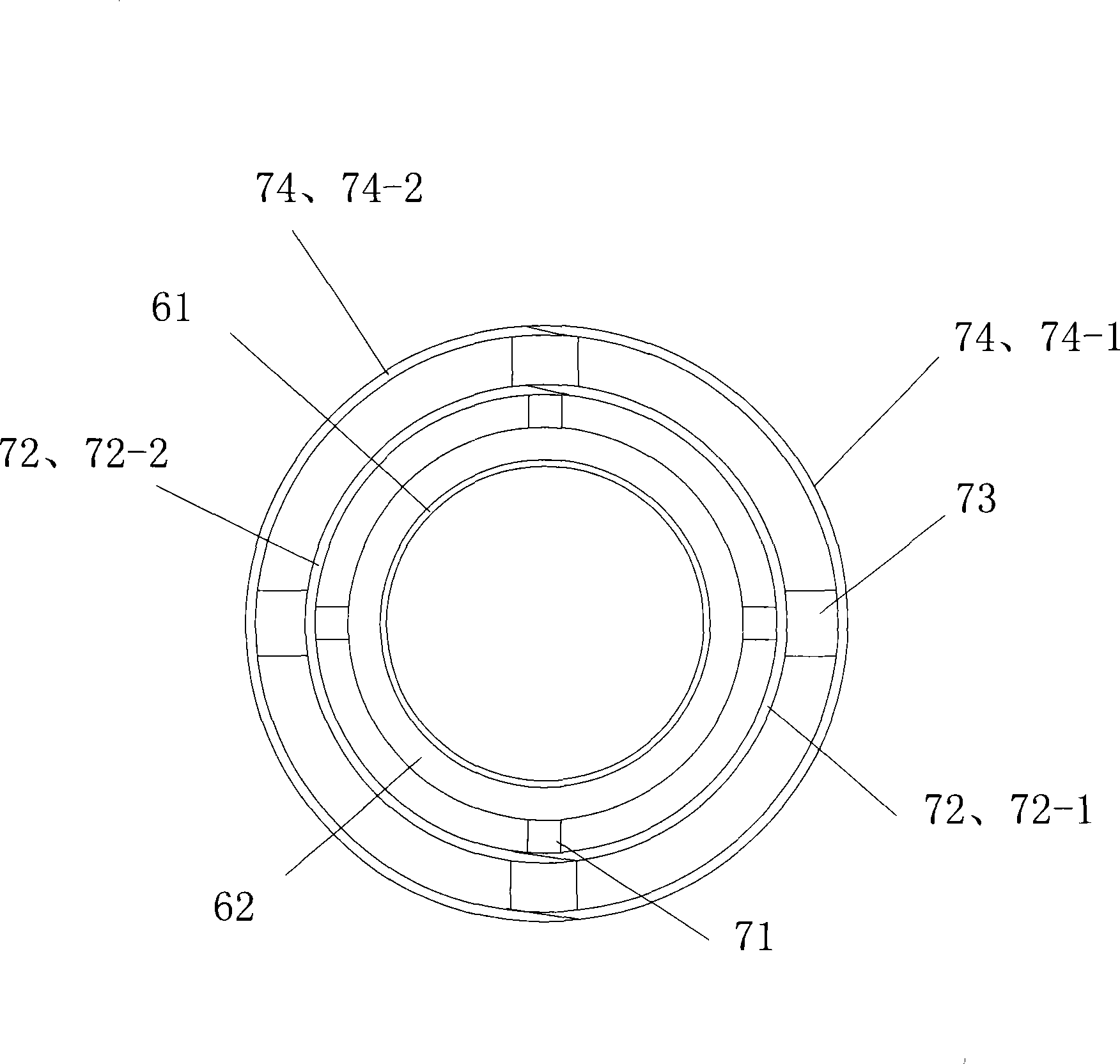

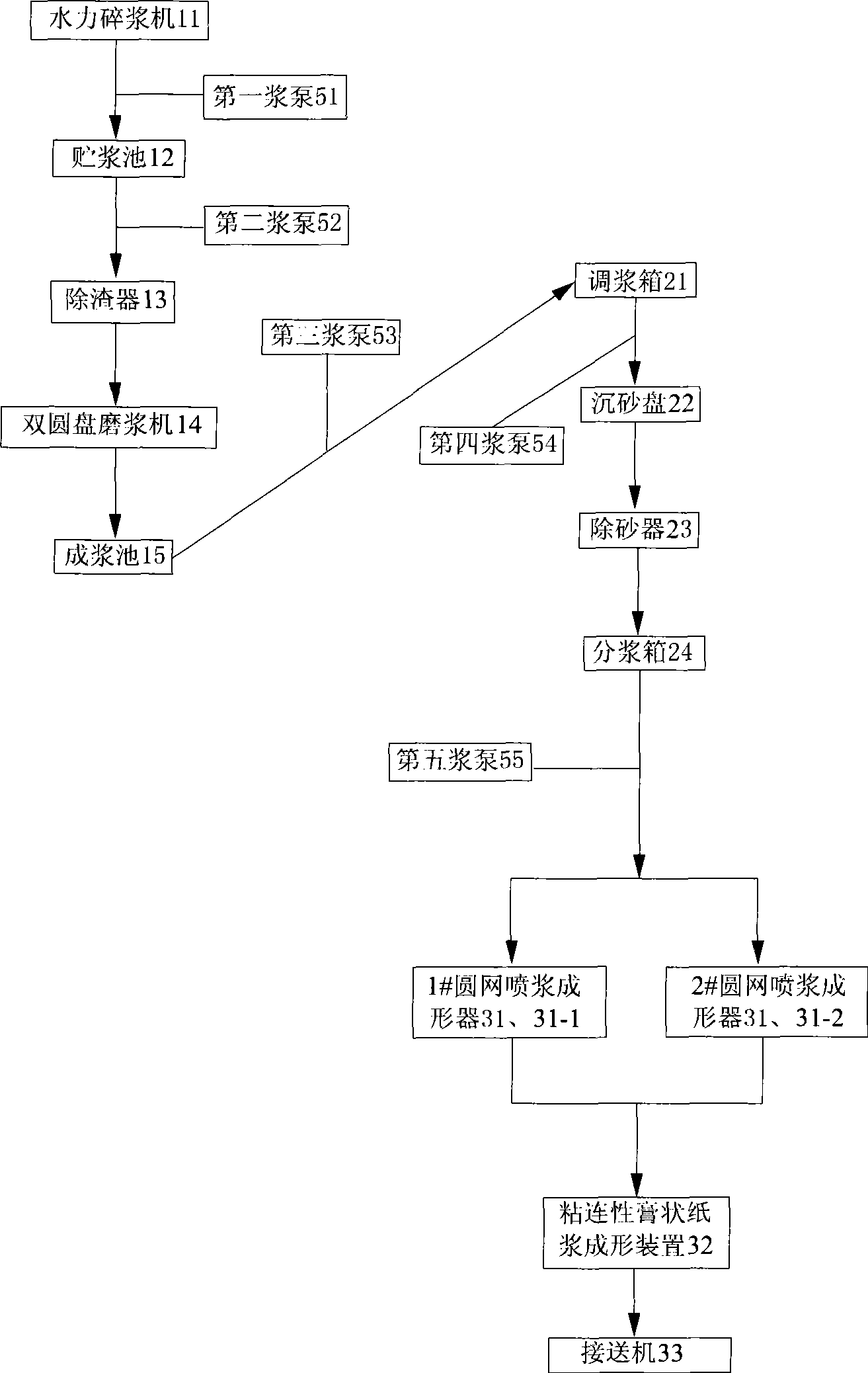

[0018] See figure 1 and figure 2 , the insulating pressure equalizing tube for ultra-high voltage or ultra-high voltage transformer of the present invention has a pressure equalizing tube 61, a pure insulating paper covering shell 62, a pure insulating paper inner ring stay 71, a pure insulating paper inner cylinder 72, a pure insulating paper Paper outer ring stays 73 and pure insulating paper outer cylinder 74. The pressure equalizing pipe 61 has two sections of straight pipes and an elbow between the two sections of straight pipes.

[0019] The pure insulating paper covering shell 62 is tightly covered on the outer wall of the pressure equalizing tube 61, the pure insulating paper inner cylinder 72 is set outside the pure insulating paper covering shell 6, and the pure insulating paper outer cylinder 74 is set on the pure insulating paper inner cylinder 72 outside. Each pure insulating paper inner ring stay 71 is arranged between the pure insulating paper covering shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com