High-precision vision angle-measurement apparatus based on lattice

A high-precision, visual technology, used in measuring devices, optical devices, instruments, etc., can solve problems such as lens distortion errors, and achieve the effect of insensitivity to errors, insensitive to rotation center movement, and insensitive to long-term temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

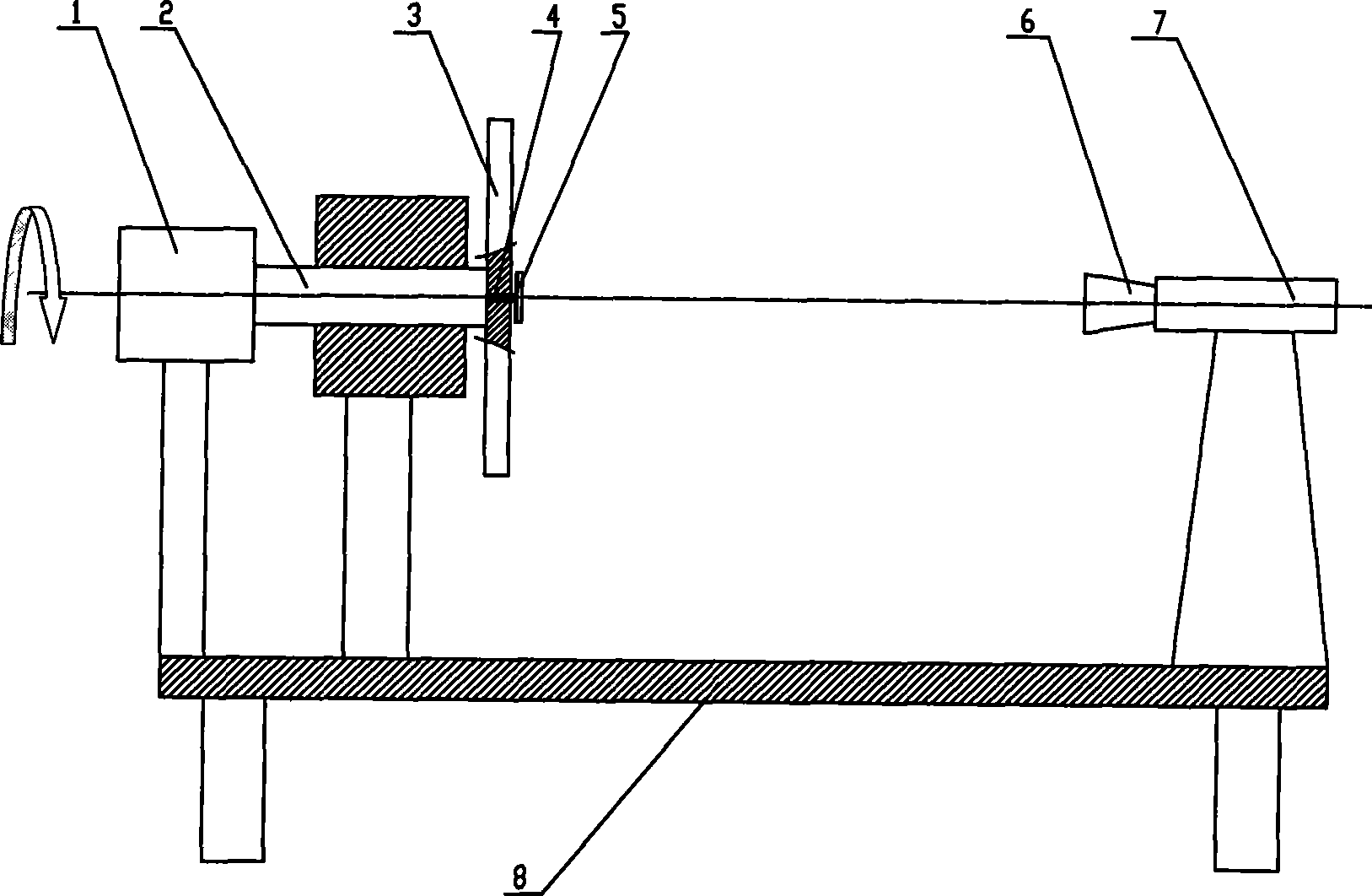

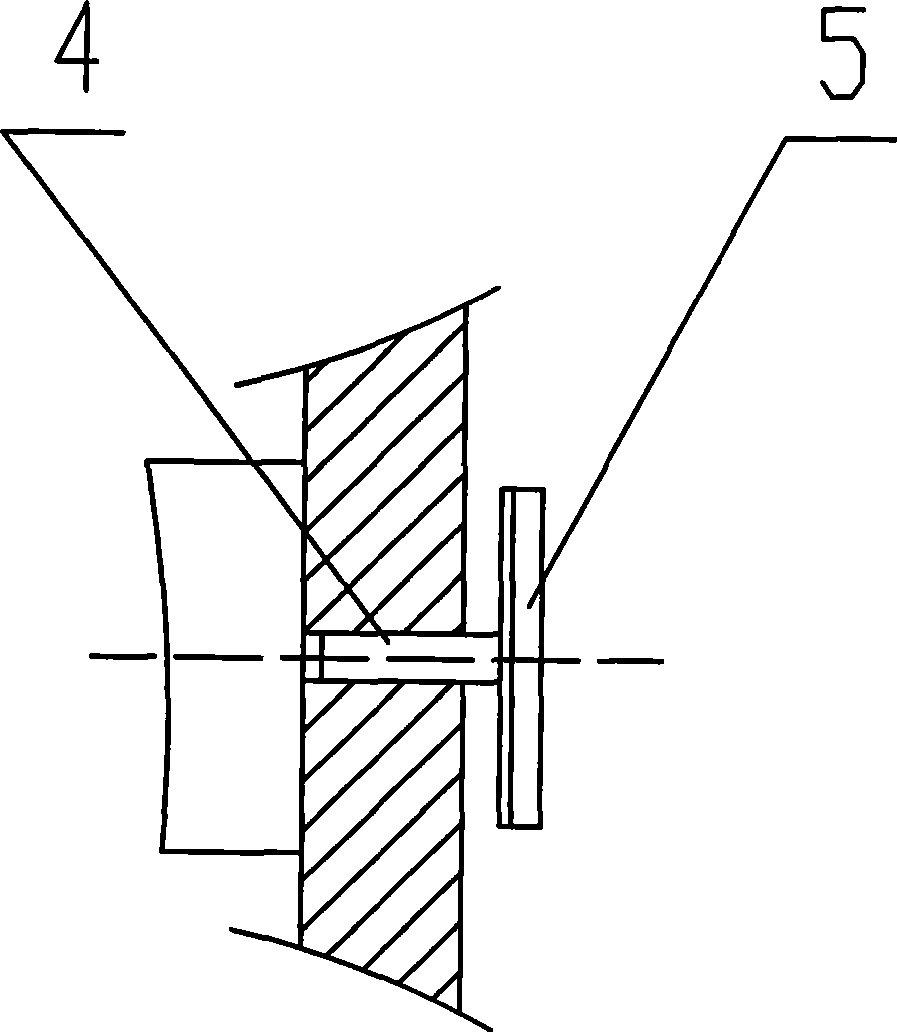

[0045] see figure 1 with figure 2 , the high-precision visual angle measuring device based on the dot matrix includes a frame 8, and the upper side of the workbench of the frame 8 is provided with a driving part 1, and the driving part 1 is a stepping motor or a servo motor, and the indexing accuracy is high; the driving part 1 The output end of the rotating part 2 is connected to the rotating part 2, and the other end of the rotating part 2 is connected to the tested rotating disk 3. A standard target 5 is coaxially installed on the outer surface of the tested rotating disk 3 through the positioning shaft 4; on the other side of the workbench A CCD camera 7 is installed through the bracket, and the imaging lens 6 of the CCD camera 7 is coaxially corresponding to the standard target 5;

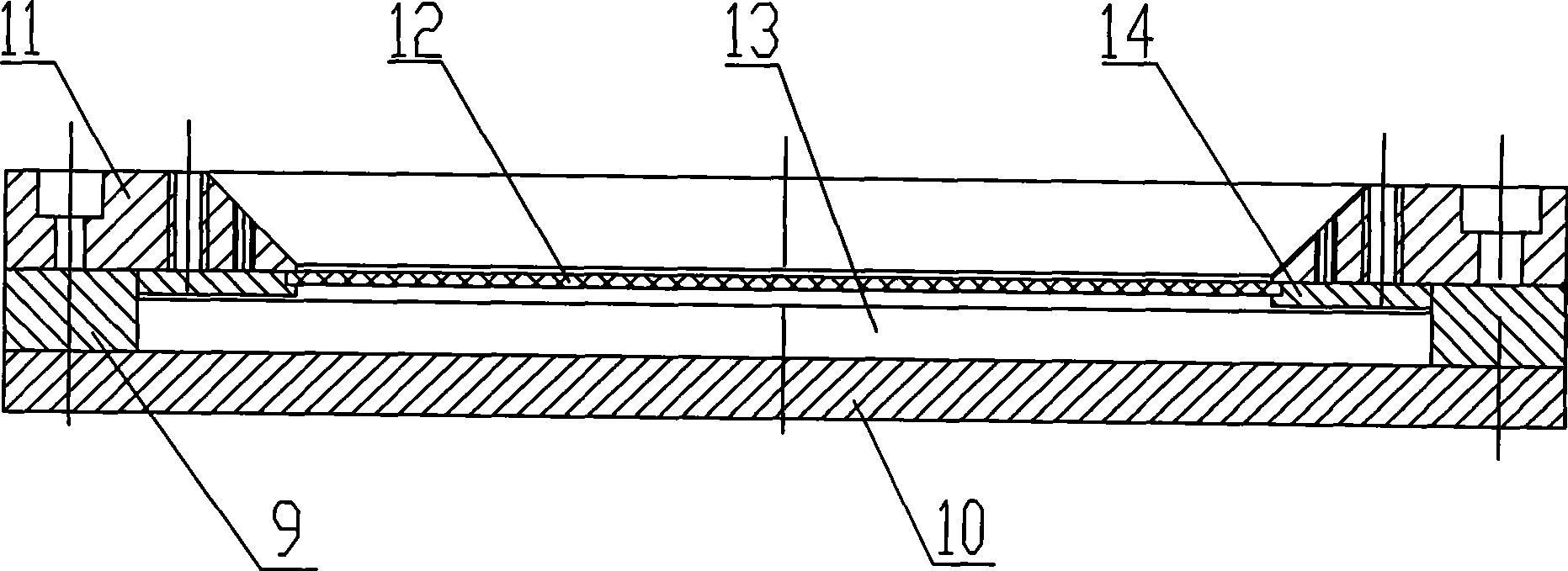

[0046] The standard target 5 includes a glass mirror shading plate 12, the glass mirror shading plate 12 is embedded in the inner side of the square frame-shaped fixing plate 11, and is fixe...

Embodiment 2

[0064] The distance between the standard target and the imaging lens is 0.75-20 meters. Others are with embodiment 1.

[0065] When used for large-angle measurement, the measurement range is 0°~360°, and the measurement accuracy is 2 arc seconds. For example, when measuring the rotating platform of an astronomical telescope, the standard target 5 is first connected to the positioning axis 4 of the rotating disk 3 under test. Then, through the imaging lens, the standard target light point array image is obtained, and the image plane coordinates (x, y) of 29×29 light points are obtained through the feature point detection algorithm, and the formula (u, v) of the object plane coordinates (u, v) is obtained 1), (2):

[0066] u=a 0 +a 1 x+a 2 y+a 3 x 2 +a 4 the y 2 +a 5 xy+a 6 x 3 +a 7 the y 3 +a 8 x 2 y+a 9 xy 2 (1)

[0067] +a 10 x 4 +a 11 the y 4 +a 12 xy 3 +a 13 x3 y+a 14 x 2 the y 2

[0068] v=b 0 +b 1 x+b 2 y+b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com