Wafer detection system

A detection system and wafer technology, applied in the direction of measurement devices, electronic circuit testing, semiconductor/solid-state device testing/measurement, etc., can solve problems affecting the overall production capacity output, incompatibility, inaccurate detection results, etc., to improve the detection process speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

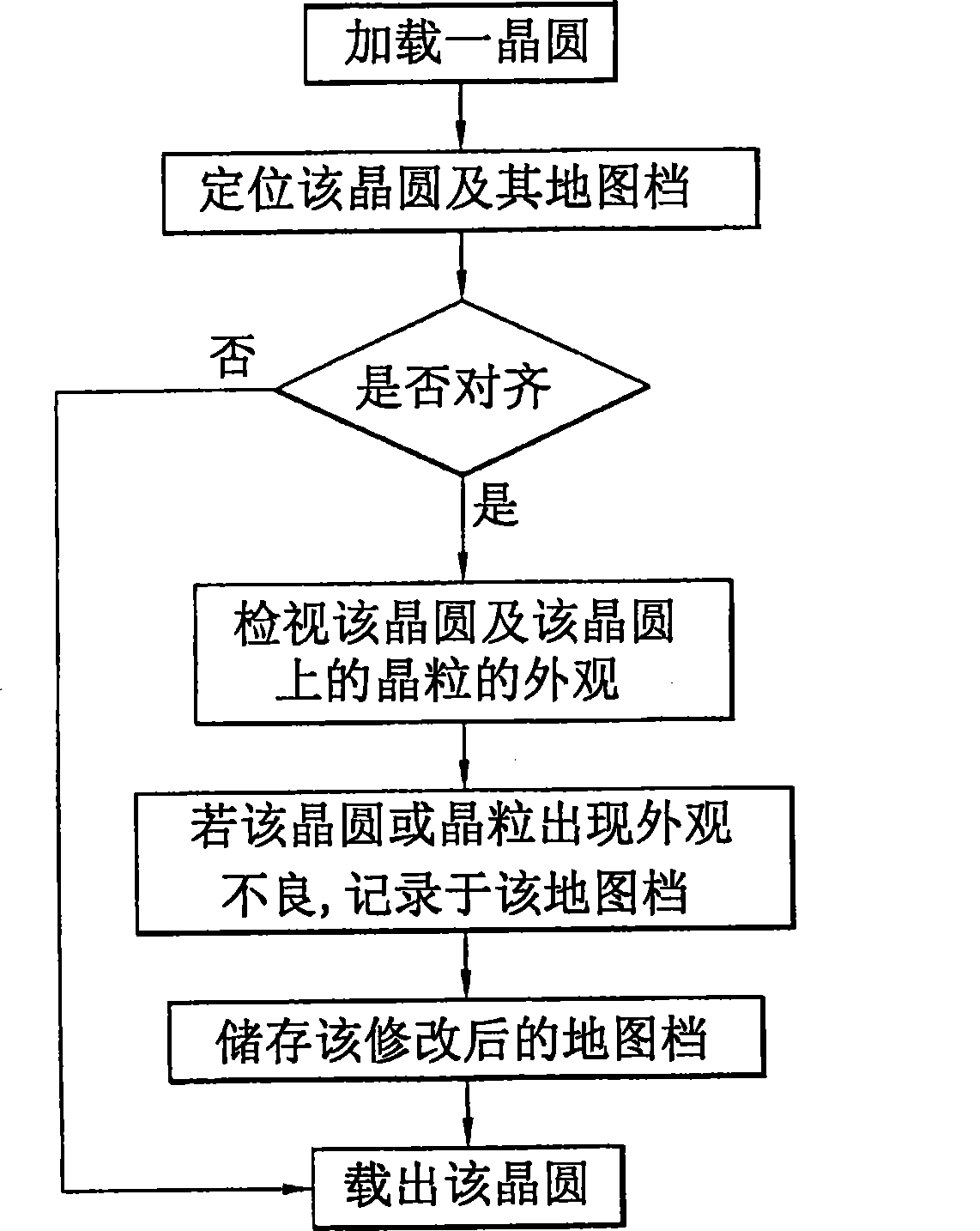

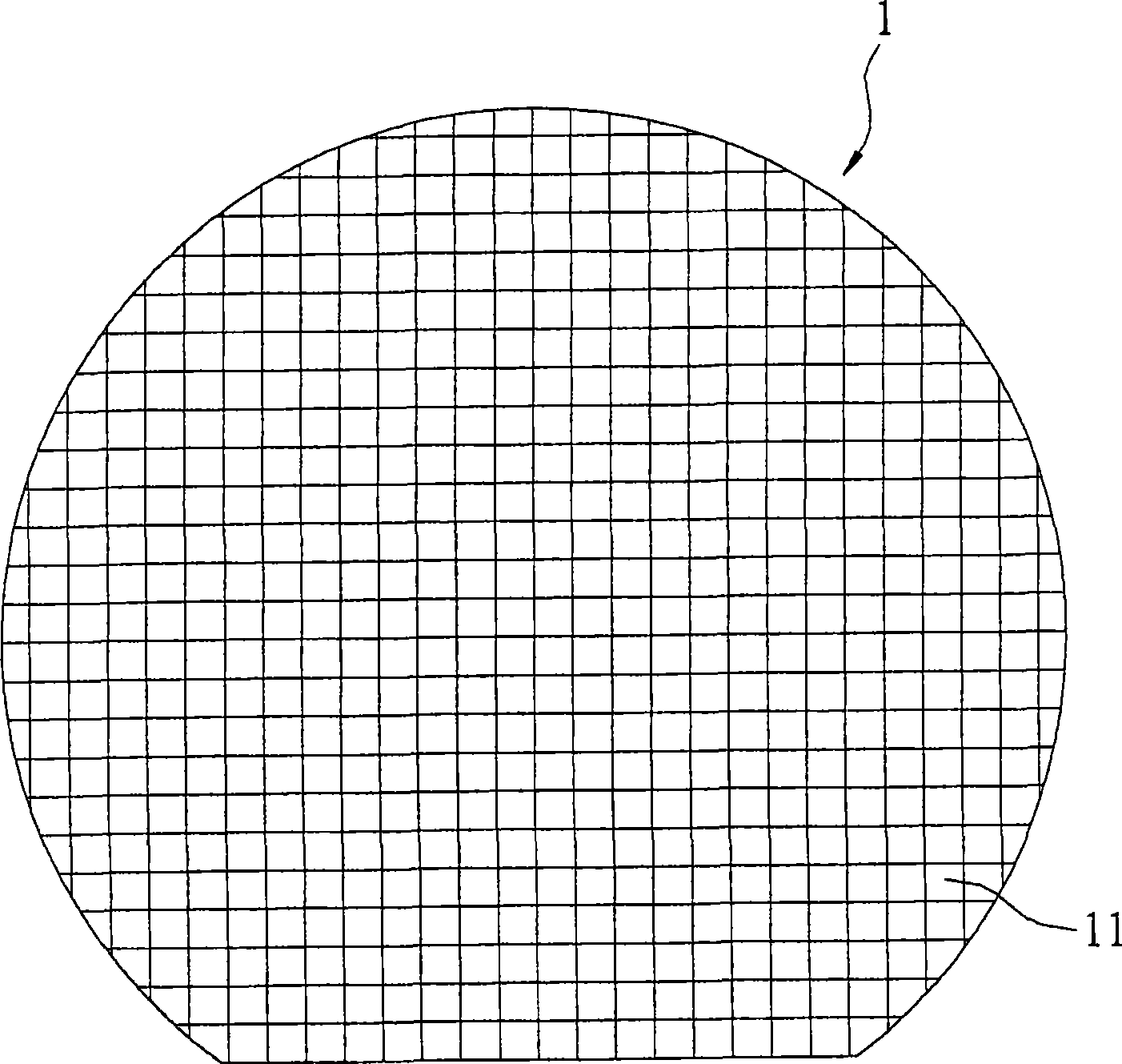

[0025] After the final process on the production line, the wafer must be diced into individual dies for packaging. However, before packaging, it is necessary to check whether the electrical function of each chip is normal, that is, use an electrical measurement probe to detect whether the electrical function of each chip is normal, and use the result of the test as a The electronic map file is output, usually the map file is in a special file format, and in this embodiment, the file format is the first file format. The existing manual inspection cannot be done in a computerized way, so the operator must first record in paper. However, in the present invention, the operation of manual inspection is applied to a production platform, so that it can directly read the electronic map file, and directly record the result of visual inspection in the map file.

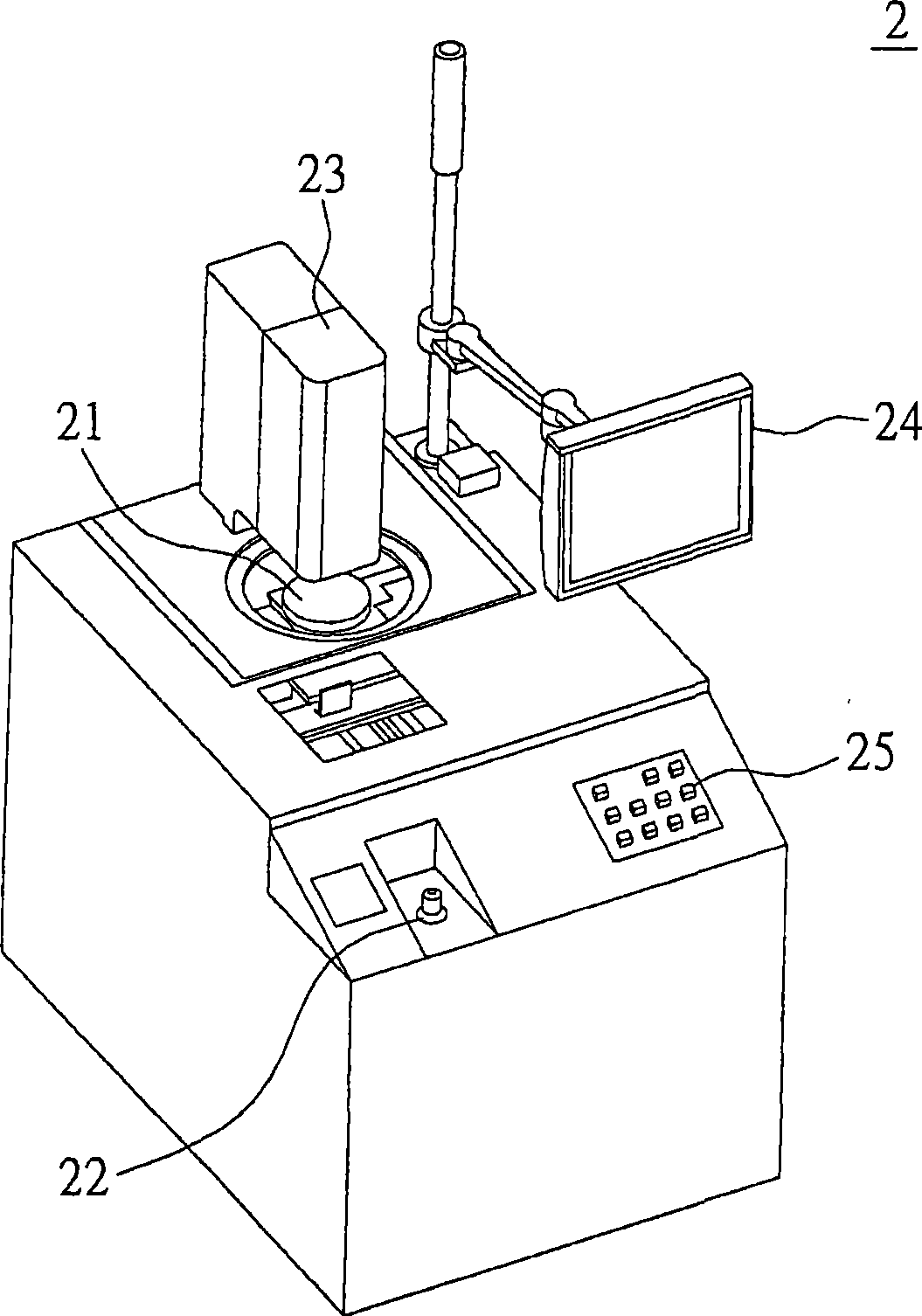

[0026] see figure 2 , the present invention provides a wafer inspection system 2, the wafer inspection system 2 is mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com