Immersed LEDs

A LED array and LED packaging technology, applied in lighting and heating equipment, electrical components, display devices, etc., can solve the problems of low luminous efficiency, unconstrained flashing, and unacceptable performance, so as to avoid total internal reflection and improve The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

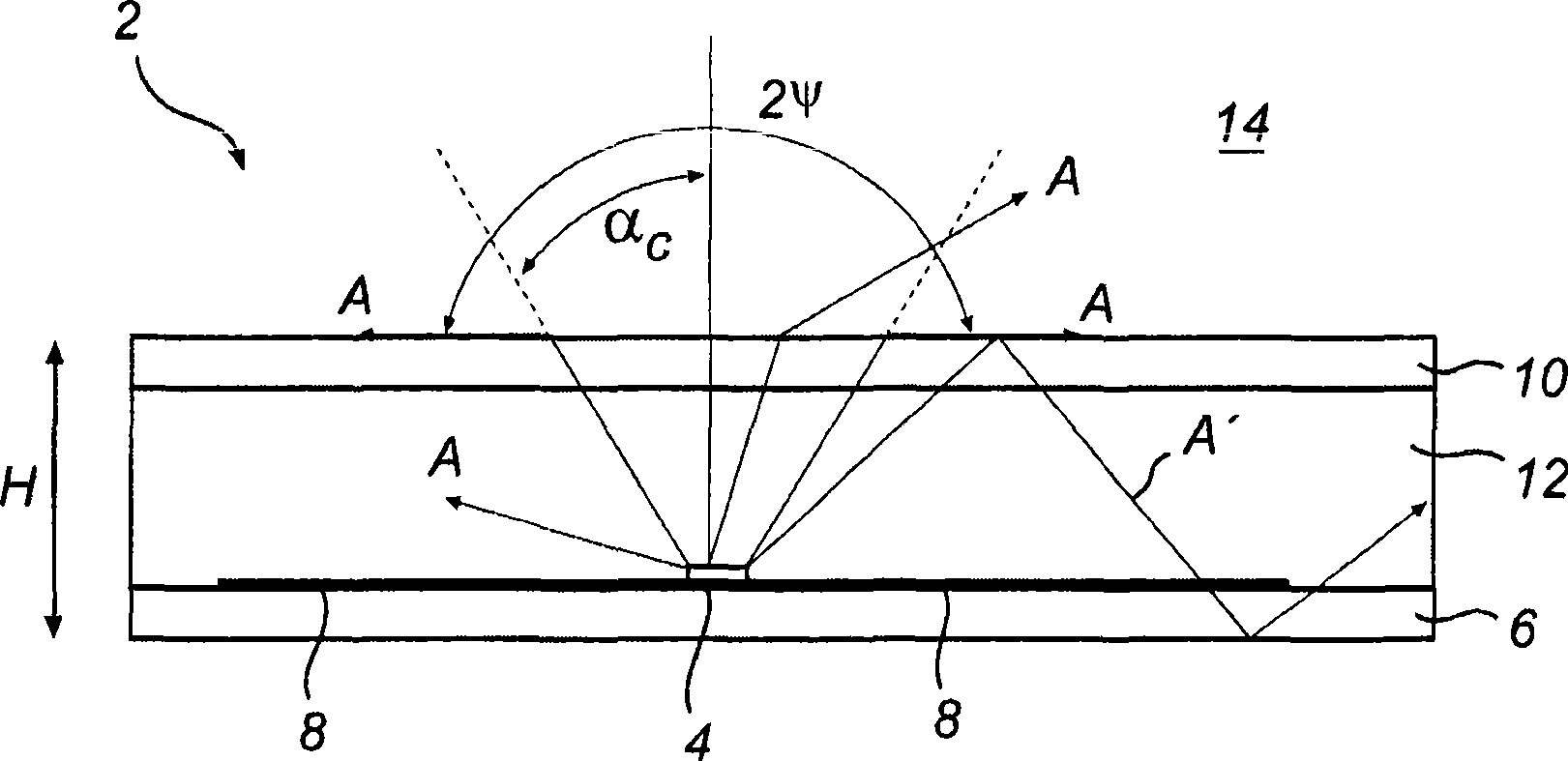

[0025] figure 1 A part of a system 2 is shown schematically, in which a Lambertian LED 4 is arranged on a glass plate substrate 6 . On the substrate 6 is a transparent conductor 8 that supplies current to the LED 4 . The LED 4 is sandwiched between the substrate 6 and the glass top plate 10, and is immersed in a polymer 12, typically polyvinyl butyral (PVB), which also provides for holding the glass plates 6 and 10 in place. cohesion together. The refractive index of PVB is close to that of glass, and it is set to 1.5 in the calculations described below. The approximate height H of the sandwich system is generally about 7-8 mm. The system is generally surrounded by air 14 . Arrow A represents the light emitted by LED4, and arrow A' represents light through total internal reflection.

[0026] The luminous efficiency η (ie, the amount of light emitted from the glass top plate 10 divided by the total amount of light emitted by the LED 4 ) of the above system is relatively lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com