Clamp for mounting component and mounting structure of component

A technology for installation and components, which is applied in the direction of vehicle components, transportation and packaging, and special positions of vehicles, etc. It can solve the problems that the elastic locking feet cannot pass through the installation holes and cannot assist the fixing of the armrest, etc., and achieve a small locking width , Rigidity reduction, load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

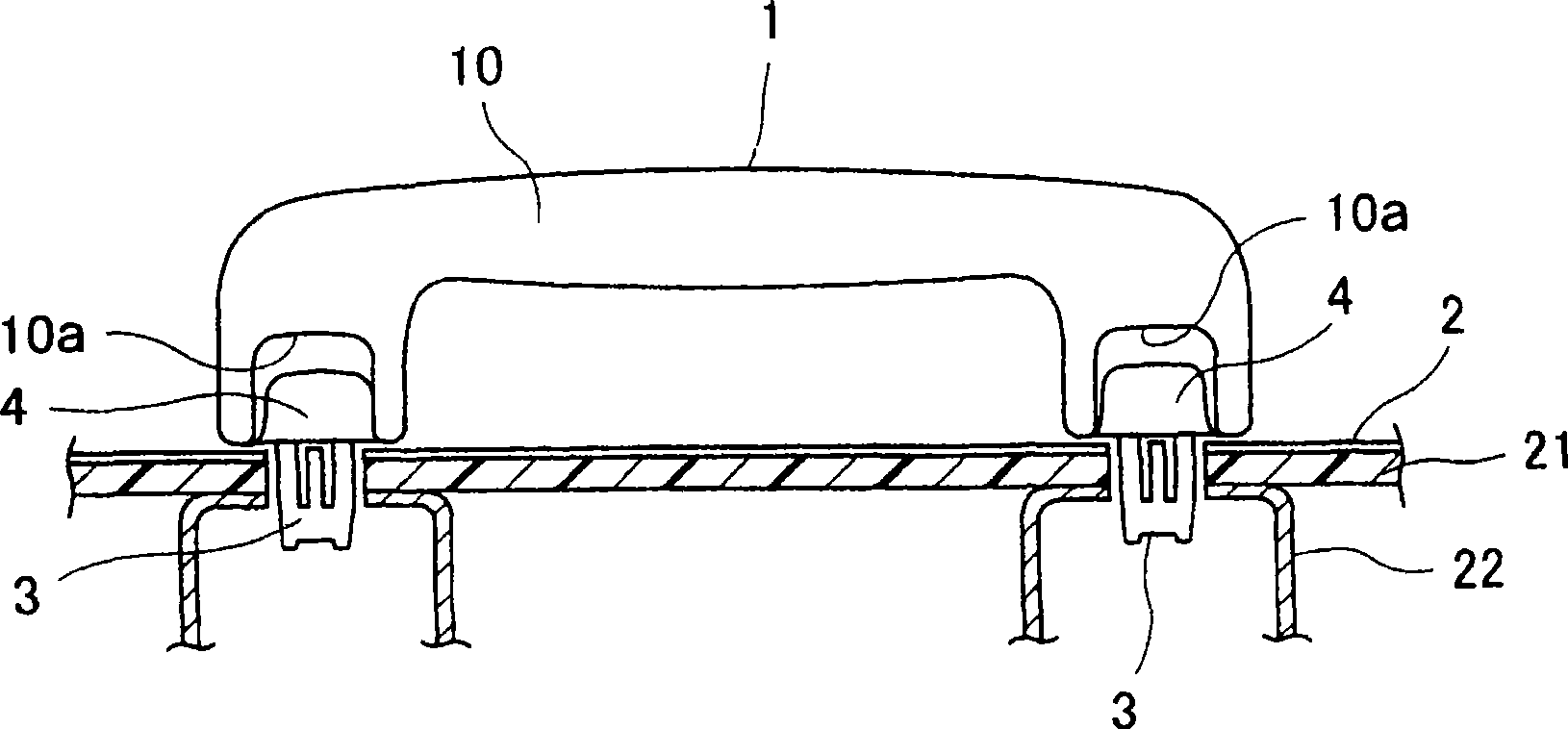

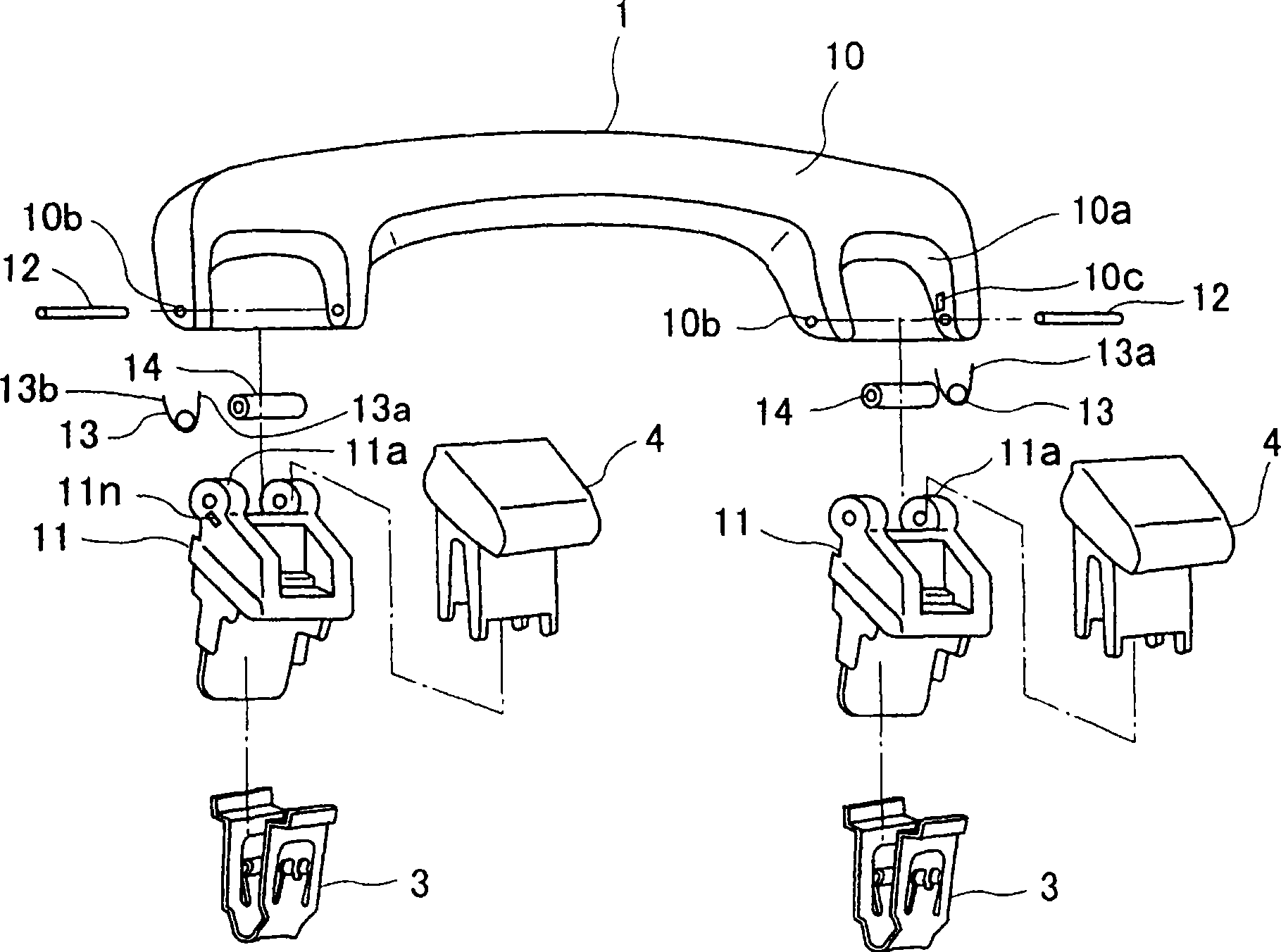

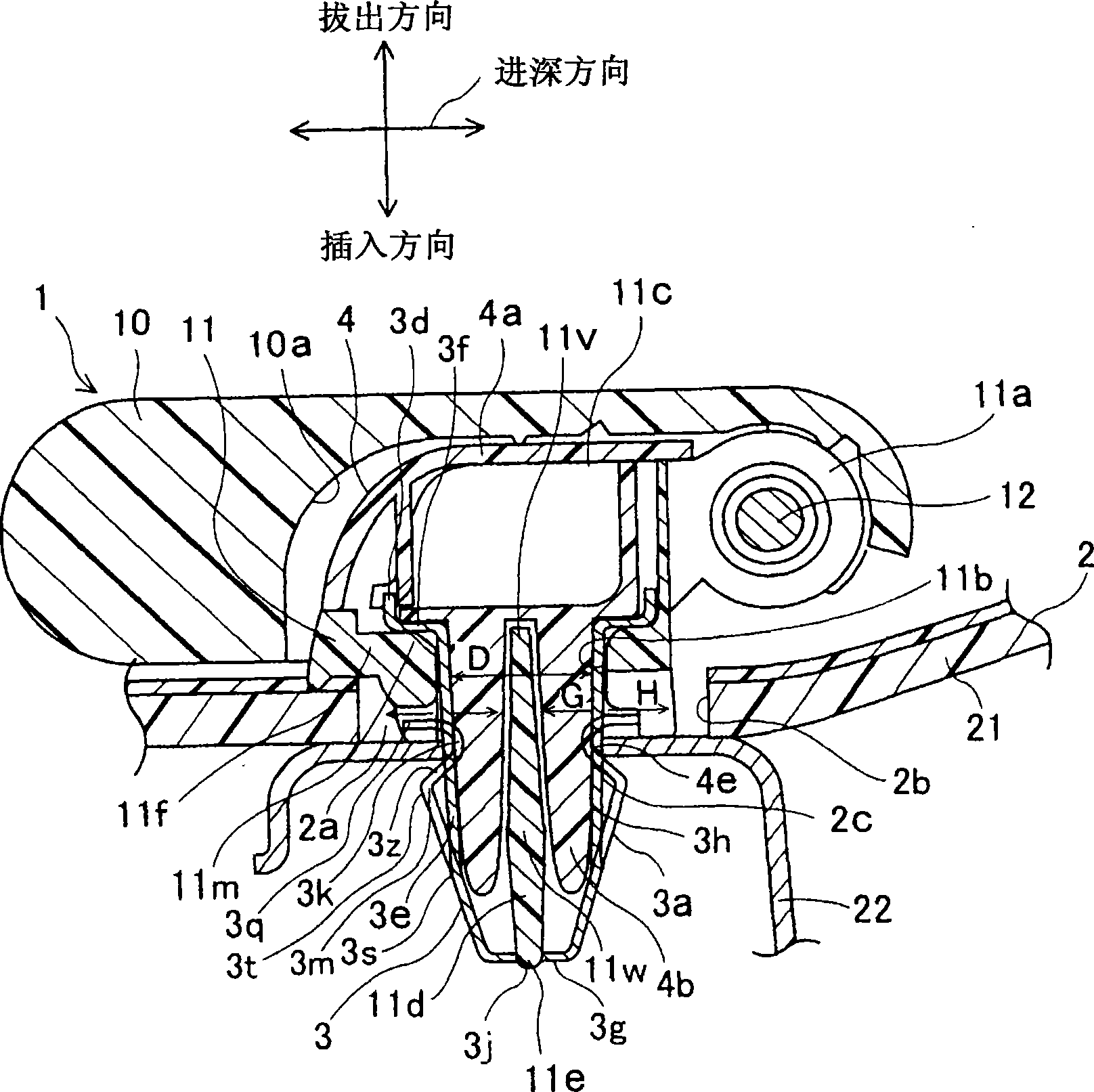

[0033] Embodiment 1 according to the present invention will be described with reference to the drawings. figure 1 It is a front view of the installation structure for attaching the auxiliary armrest to the side panel of the vehicle. figure 2 It is an exploded oblique view of the mounting structure. Such as figure 1 , figure 2 As shown, the auxiliary grab bar 1 is mounted on the vehicle side panel 2 using the clamp 3 and the cover portion 4 .

[0034]The auxiliary armrest 1 includes: an armrest body 10 ; and bases 11 provided at both ends of the armrest body 10 and supporting the armrest body 10 rotatably. Both ends of the armrest main body 10 have recesses 10 a for accommodating the base 11 . The shaft hole 10b is opened on the side wall of the recessed portion 10a. The armrest body 10 is rotatably supported on the base 11 by inserting the shaft 12 into the shaft hole 10 b and the hole of the bearing portion 11 a provided on the base 11 . In addition, a spring 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com