Large caliber acoustic velocity-variable supercharging heat-exchanging system

A heat exchange device and large-diameter technology, which is applied in the field of heat exchange, can solve the problem that the variable sound speed pressurized heat exchange device cannot meet the use requirements, the heat exchange process cannot be carried out in a stable state, and the safety accidents of pipelines and heat exchange equipment, etc. problems, to achieve light weight, reduce pollutant emissions, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

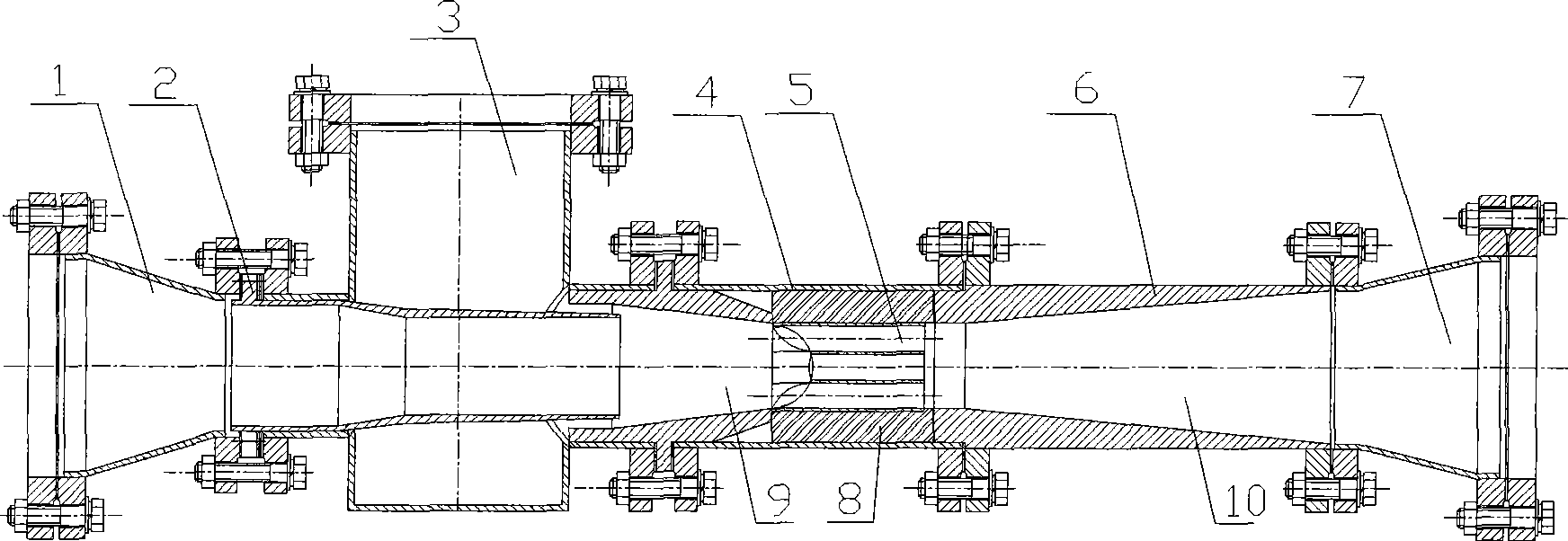

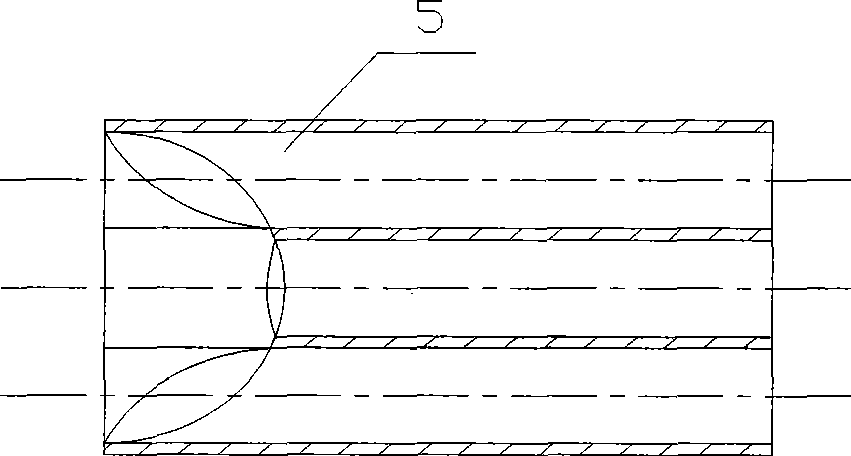

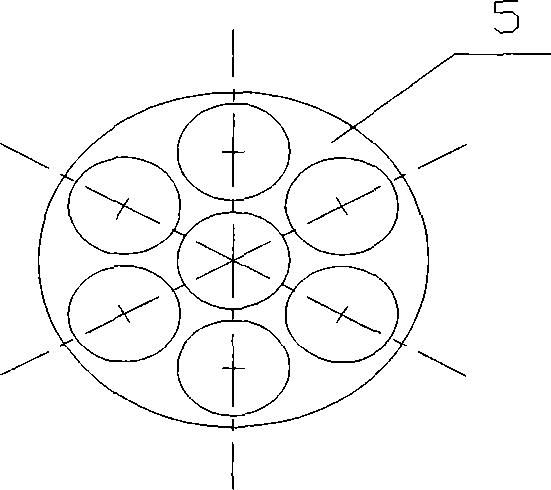

[0016] like figure 1 As shown: the device in this embodiment is mainly composed of front variable diameter 1, steam nozzle 2, three-way 3, short two-way 4, rear mixing chamber 5, long two-way 6, rear variable diameter 7, bushing 8, front mixing Chamber 9 constitutes. Wherein the end faces of the front variable diameter 1, the tee 3, the short two-way 4, the long two-way 6 and the rear variable diameter 7 are all flange structures. The steam spray pipe 2 is coaxially inserted into the tee 3, and is fixedly connected with the front reducer 1 and the tee 3 by means of the flange end face and the insertion end face through bolts and maintains coaxiality. One end of the tee 3 is connected with the front reducer 1, and the other end is connected with one end of the short two-way 4. The front mixing chamber 9 is connected with the inner diameter of the tee 3 and the short two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com