Batch allocating pore and method for predicting pore quantity

A hole and quantity technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of difficult to judge the number of holes, not large enough, waste of manpower and time, etc., to achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

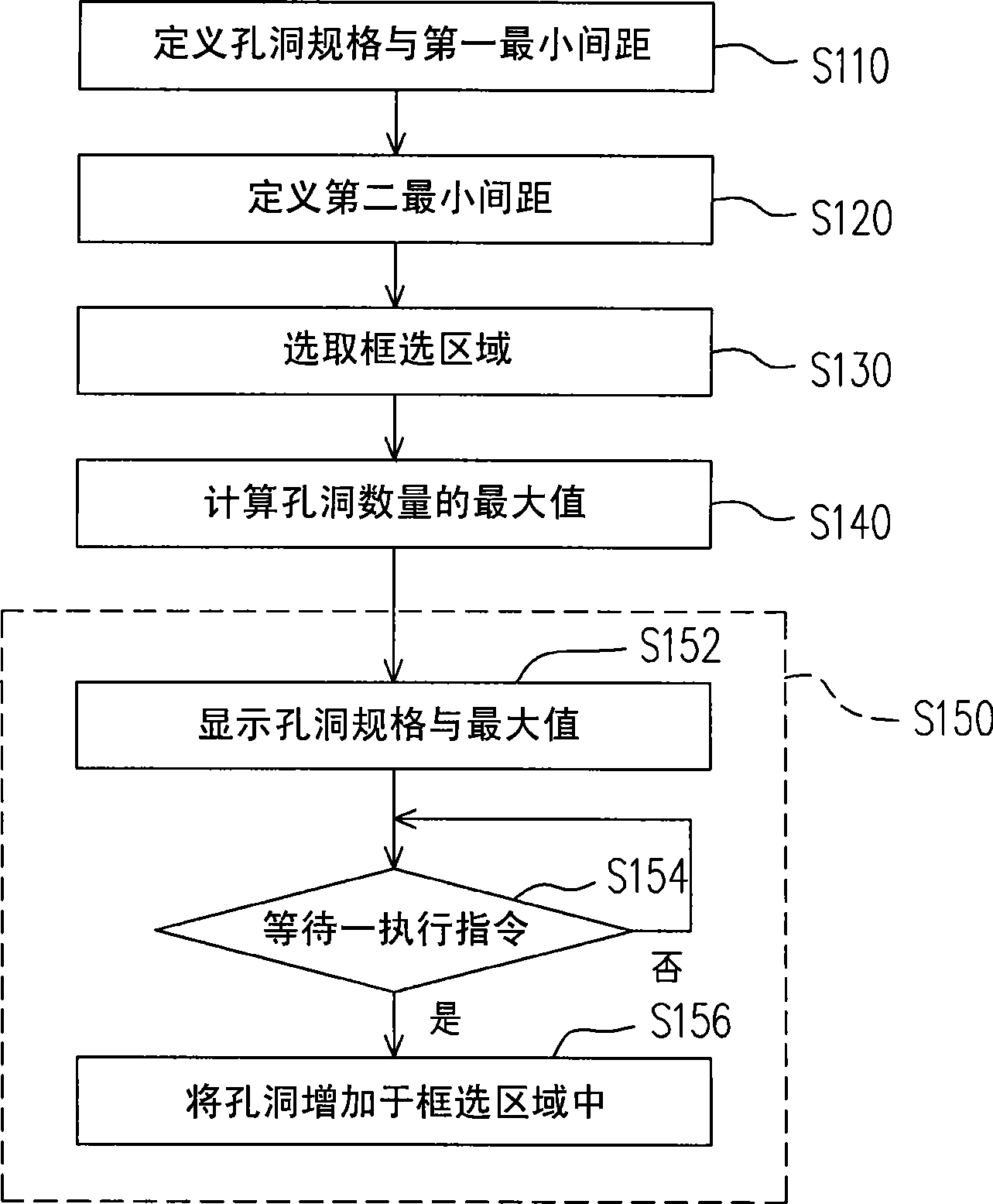

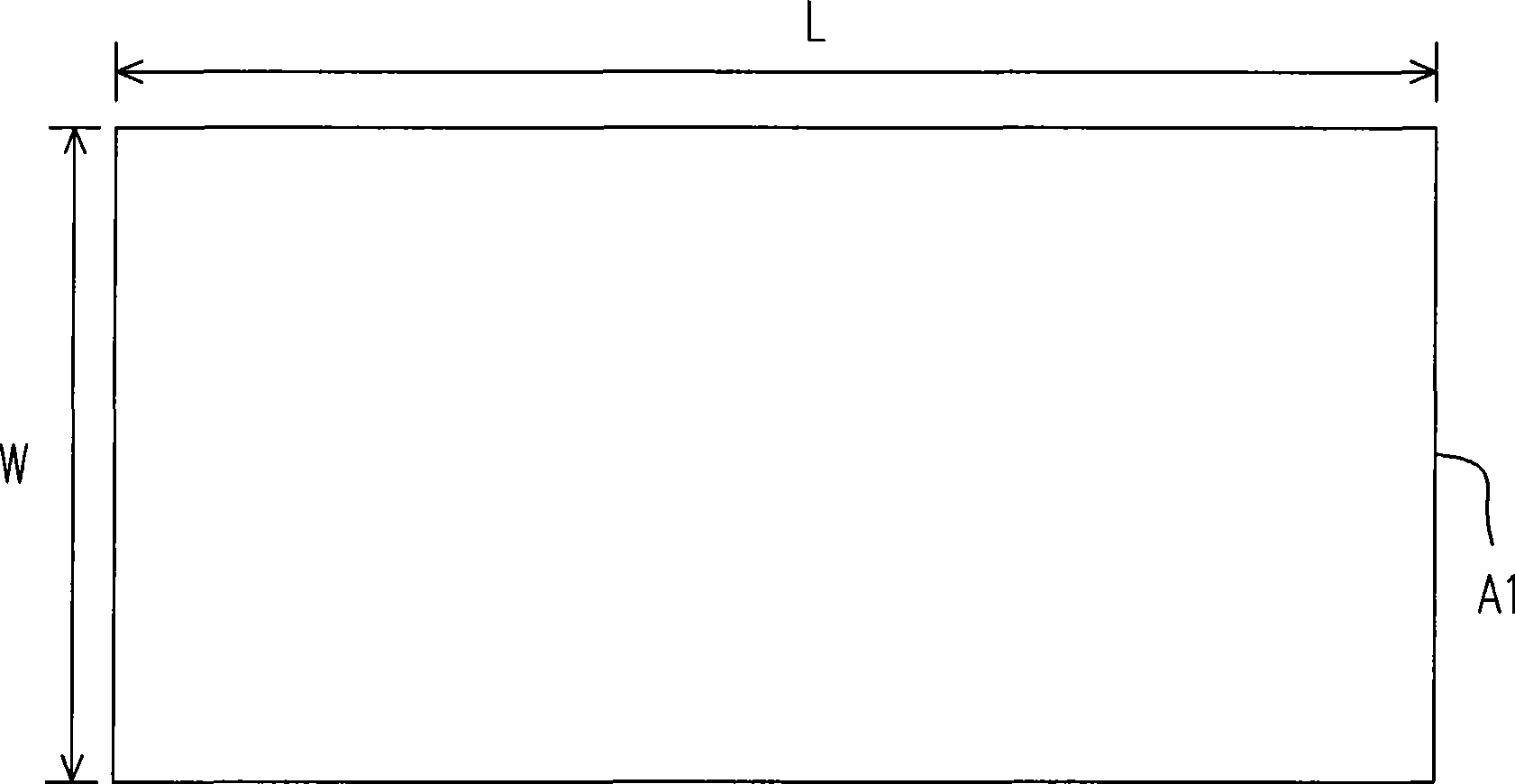

[0030] figure 1 A flowchart of a method for configuring holes for a batch according to an embodiment of the present invention. Figure 2A A schematic diagram of the copper area of a circuit board. Please refer to figure 1 and Figure 2A , the copper-clad region A1 has a length L and a width W. When multiple holes H are to be configured on the copper laying area A1 (such as Figure 2D ), step S110 is first performed to define a first minimum distance D1 between at least one hole specification and adjacent holes H. For example, the hole specifications of the holes H and the first minimum distance D1 input by the user may be received, or the set values may be automatically generated according to a preset specification table (nettype). In this embodiment, the hole specification includes, for example, the diameter O1 of the hole H. As shown in FIG.

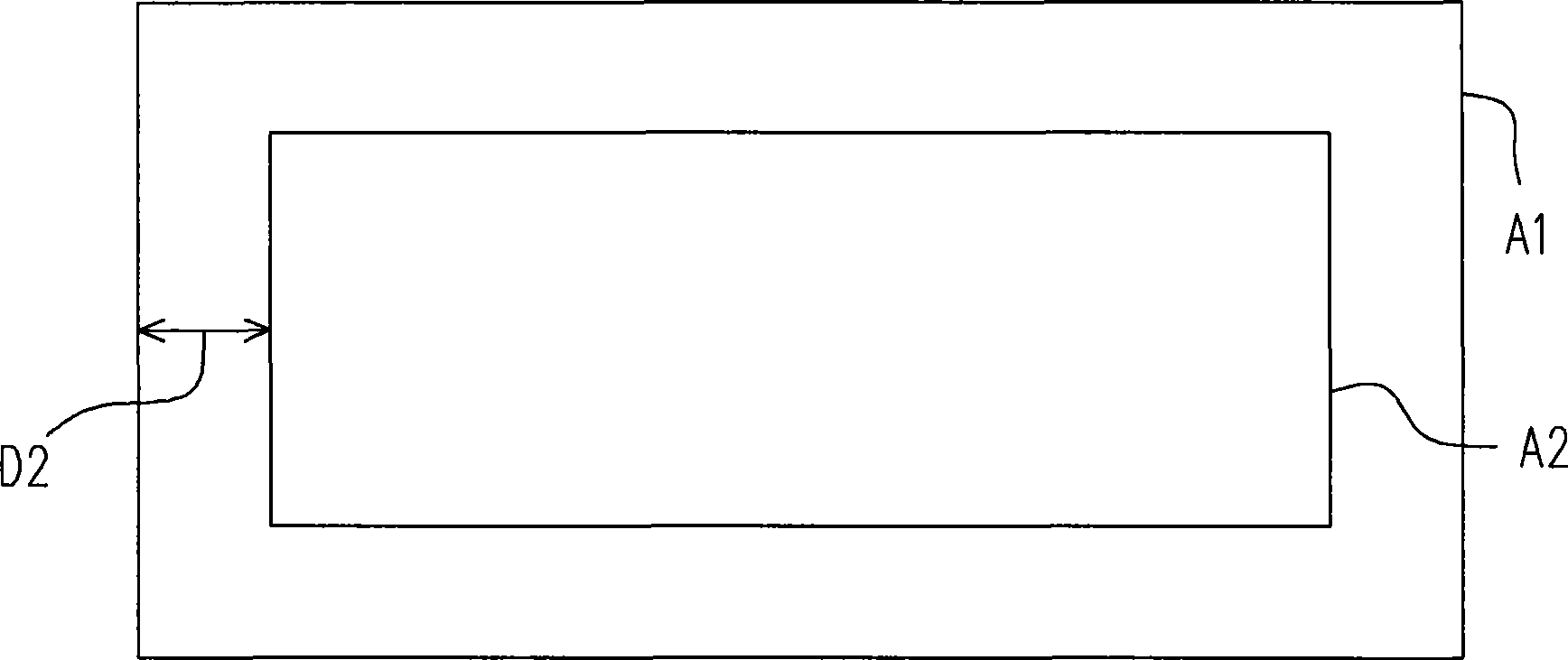

[0031] Next, step S120 may be performed to define a second minimum distance D2 of each hole H relative to a trace (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com