Method for manufacturing antenna element and antenna module with the same

A technology of antenna elements and antenna modules, which is applied to antenna components, antennas, folding antennas, etc., can solve the problems of difficult programming of laser processing and prolonged laser processing time, and achieve the best assembly convenience and reworkability. Time-saving, easy-to-adjust or transform effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the accompanying drawings.

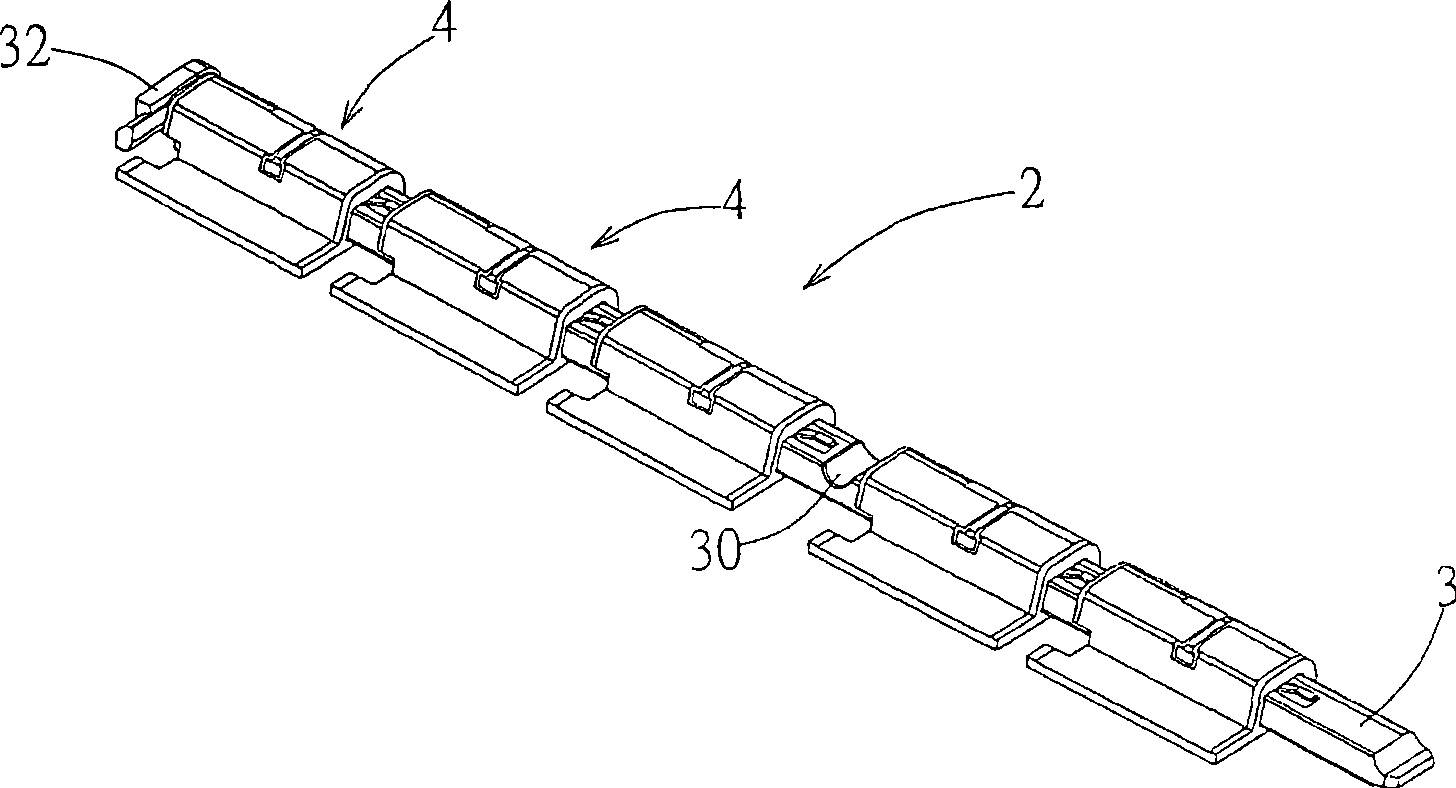

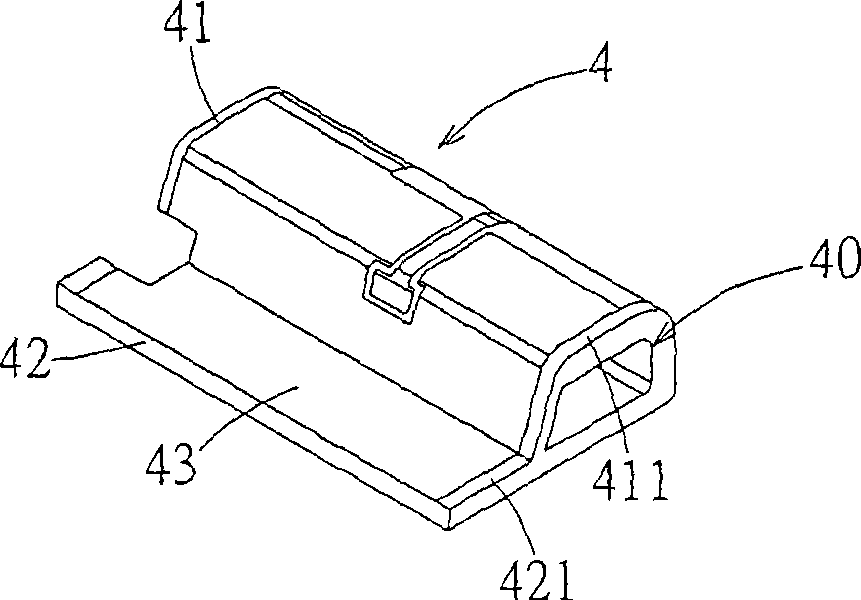

[0058] refer to Figure 1 ~ Figure 3 The first preferred embodiment of the MID antenna module 2 of the present invention includes an antenna frame 3 and a plurality of antenna elements 4 arranged on the antenna frame 3, and the MID antenna module 2 can be arranged on a notebook computer (such as Figure 6 shown) or other portable communication electronic devices to be used as the antenna of the electronic device.

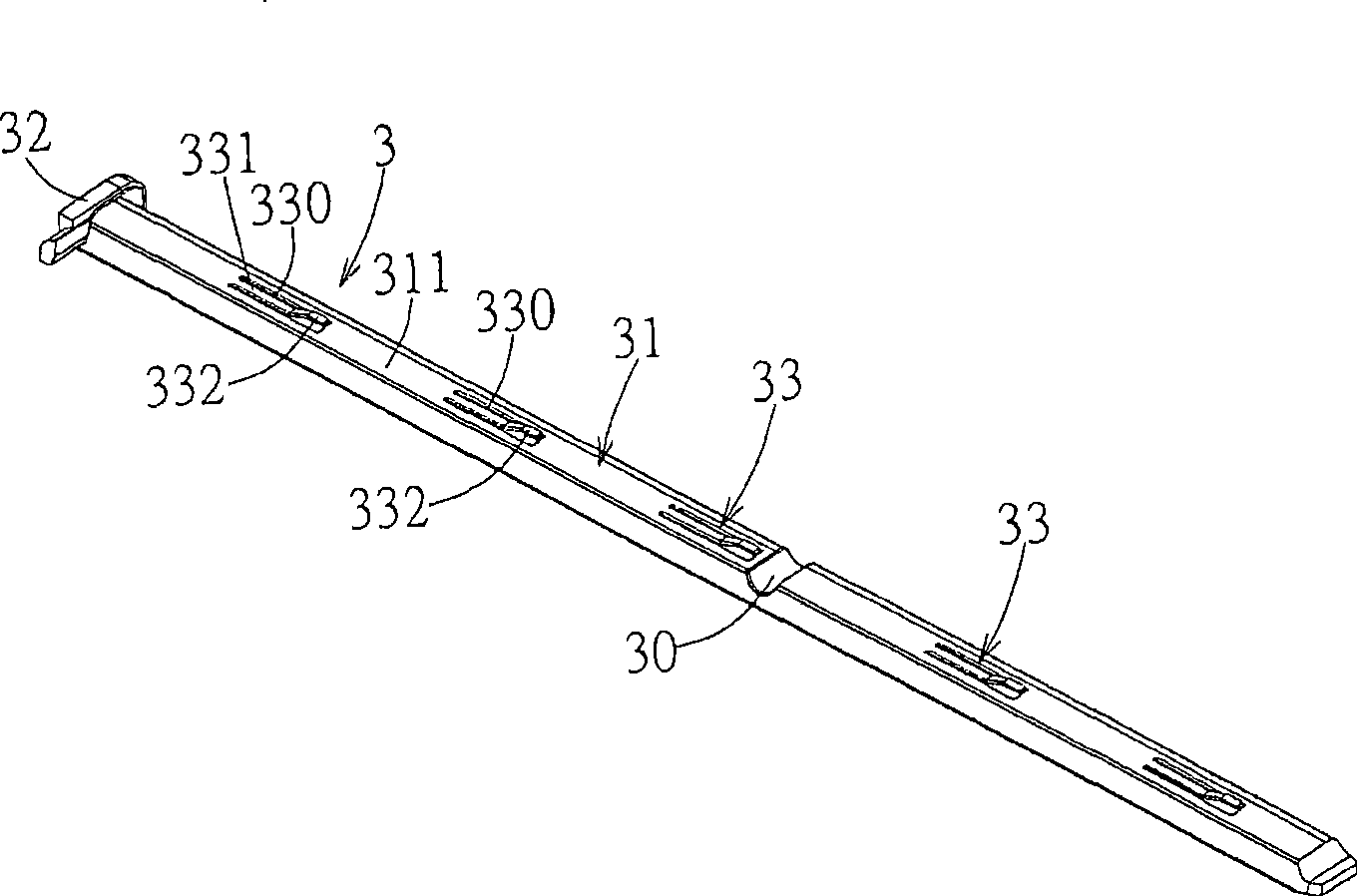

[0059] Such as figure 2As shown, the antenna frame 3 includes a generally elongated frame body 31 , a wire fixing portion 32 disposed on the frame body 31 , and a plurality of first limiting members 33 . The frame body 31 is strip-shaped and has a top wall 311 , and the frame body 31 is made of plastic material. The wire fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com