Casing tool capable of being pressed and circulated

A tool and casing technology, which is applied in the field of special tools for running casing, can solve the problems that the casing string cannot apply downward pressure, the casing running tool is simple, and the mud cannot be circulated, so as to improve efficiency and reduce bottom hole friction resistance, to ensure a smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

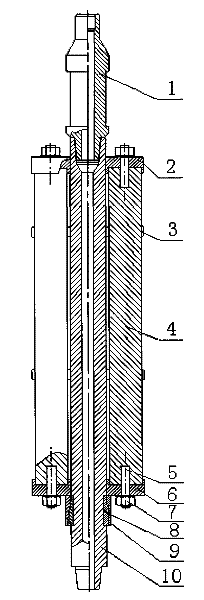

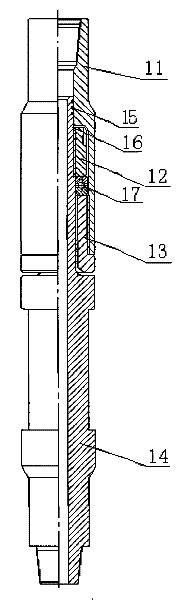

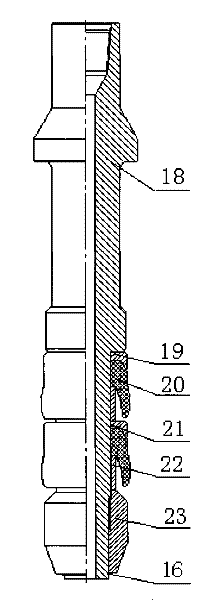

[0023] refer to Figure 4 . The casing running tool capable of pressurization and circulation is composed of three parts: a counterweight assembly 25 , a rotating assembly 26 and a circulation sealing assembly 27 . The counterweight assembly 25, the rotating assembly 26 and the circulation sealing assembly 27 are screwed together sequentially from top to bottom.

[0024] refer to figure 1 . The counterweight assembly includes a conversion joint 1, an upper fixed seat 2, a counterweight rod 4, a lower fixed seat 6, a retaining ring 8, a retaining ring outer cover 9 and a center pipe 10. The upper end of the counterweight assembly is an adapter 1. The upper end of the conversion joint 1 can be connected to the gooseneck and the high-pressure manifold through the gooseneck. There is a boss on the outer wall of the conversion joint 1 for installing an elevator, which can be used for installing an elevator during casing running construction. The lower end of the conversion joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com