Method and apparatus for checking tubular articles

A kind of object and tubular technology, applied in the field of tubular objects, can solve the problem of high cost of assembly and disassembly inspection equipment, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

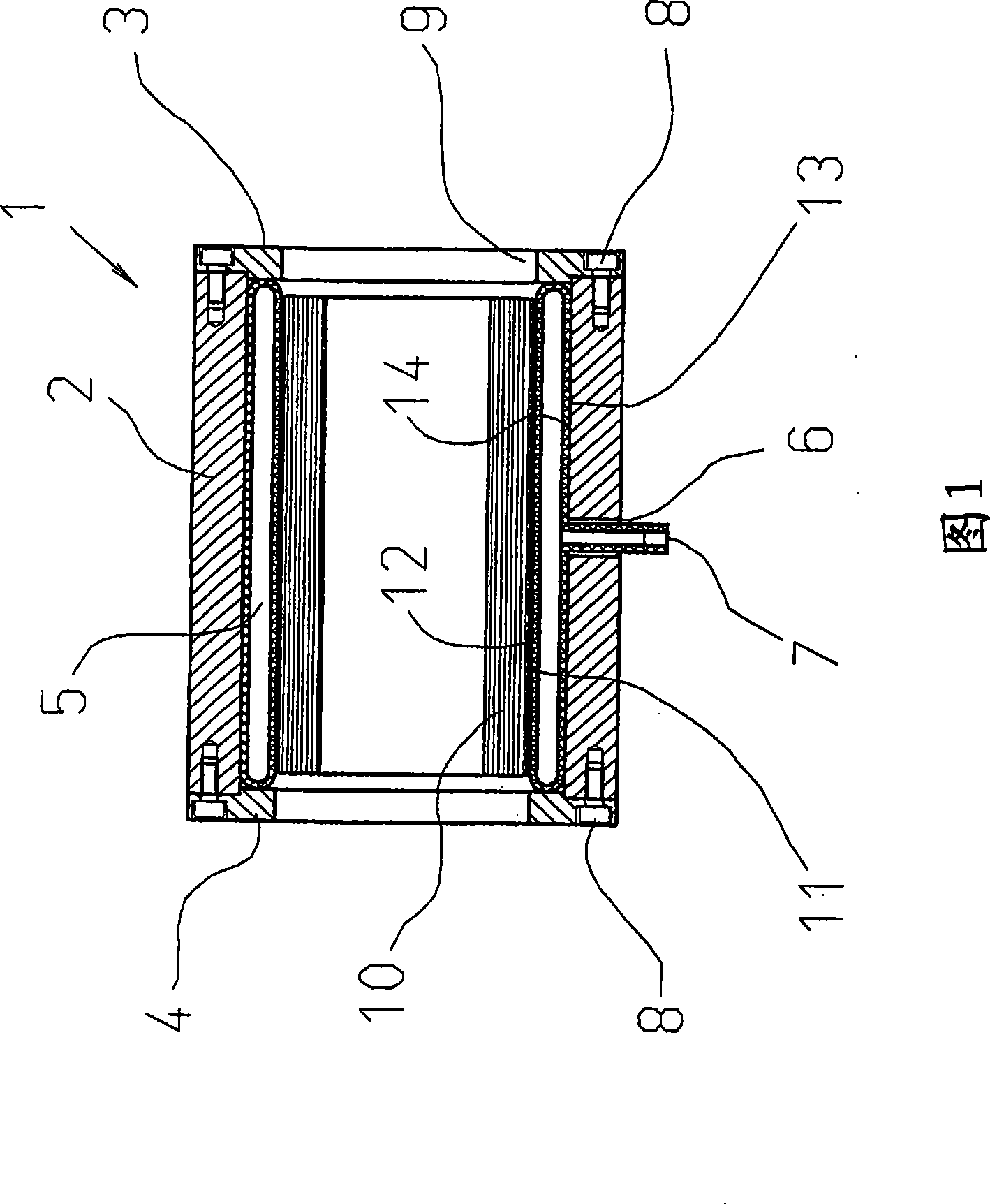

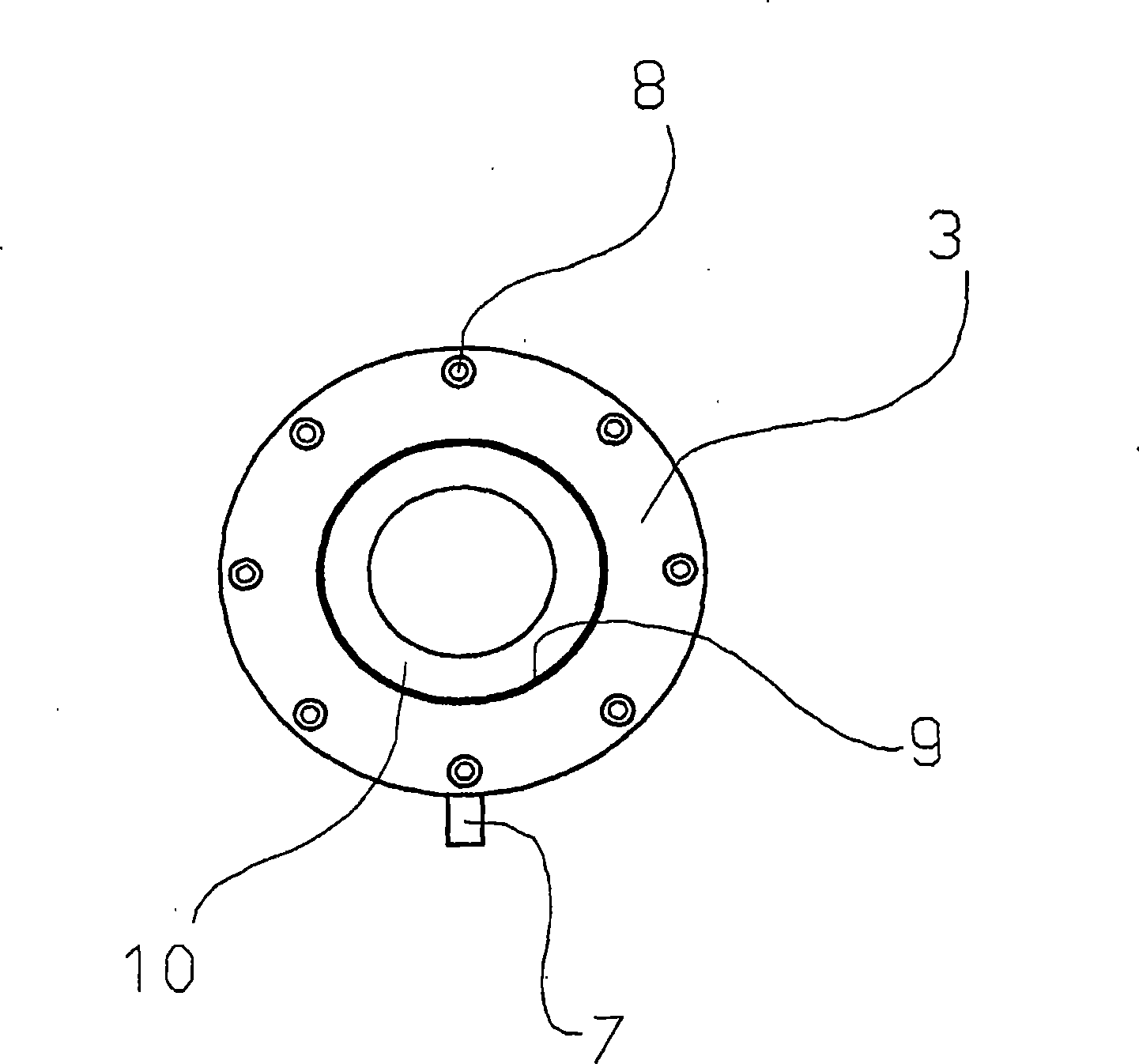

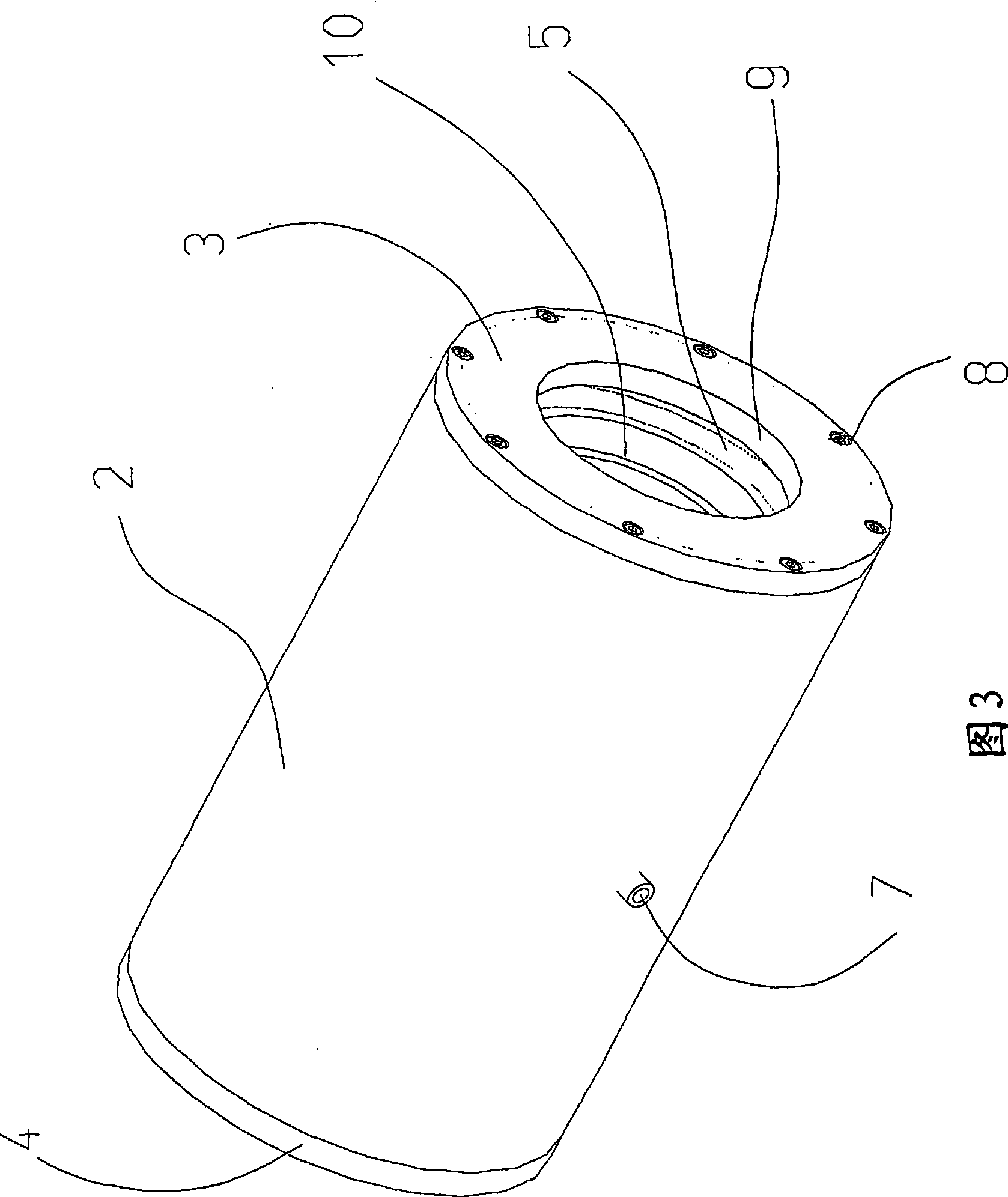

[0035] FIG. 1 shows a sectional side view of a device 1 according to the invention, which consists of a hollow cylinder 2 , two end flanges 3 , 4 and a pressure jacket 5 . The hollow cylinder 2 has an opening 6 through which a pressure medium connection 7 of the pressure jacket 5 is led to the outside. The hollow cylinder 2 is delimited at the end by two flanges 3 , 4 which are screwed to the hollow cylinder by means of fastening screws 8 . The flanges 3 , 4 have an opening 9 through which the tubular body 10 to be tested can be pushed.

[0036] For the intended application, a piece of paper tube is considered as object 10 , which is pushed into device 1 over its entire length and whose outer surface 11 is in direct contact with inner surface 12 of pressure jacket 5 . However, it is also conceivable to use the device 1 for testing other tubular bodies, for example plastic cylinders. The outer surface 13 of the pressure jacket 5 bears against the inner surface 14 of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com