Latch needle

A technology of latch needles and needle bars, which is applied in the field of latch needles and can solve problems such as the reduction of the opening width of the needle hook

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

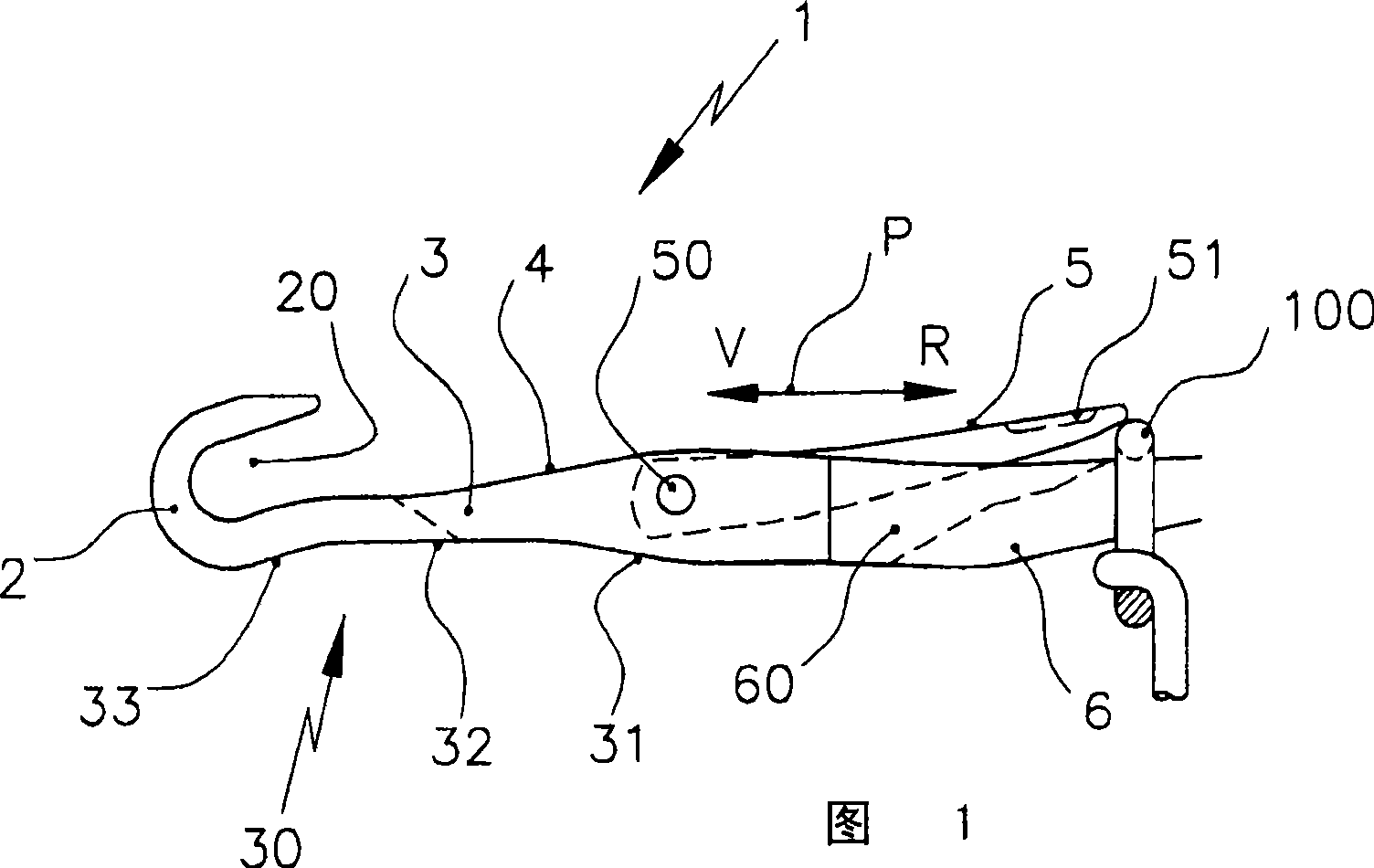

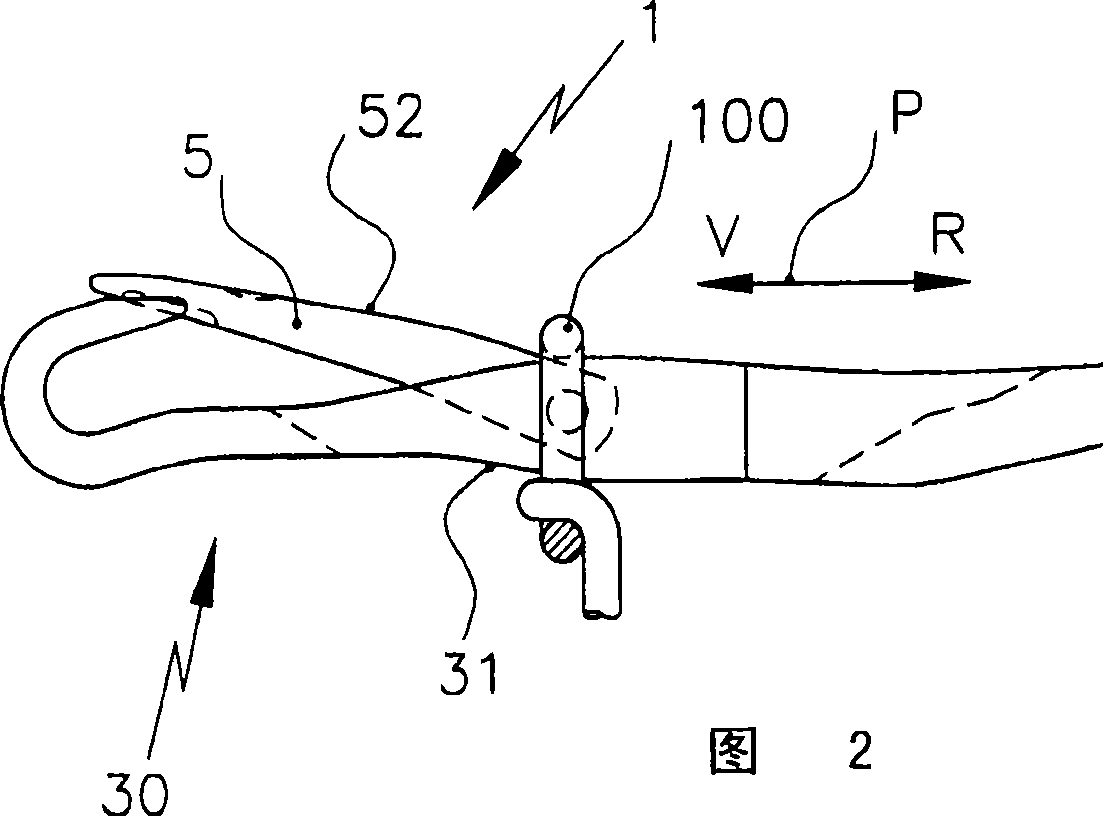

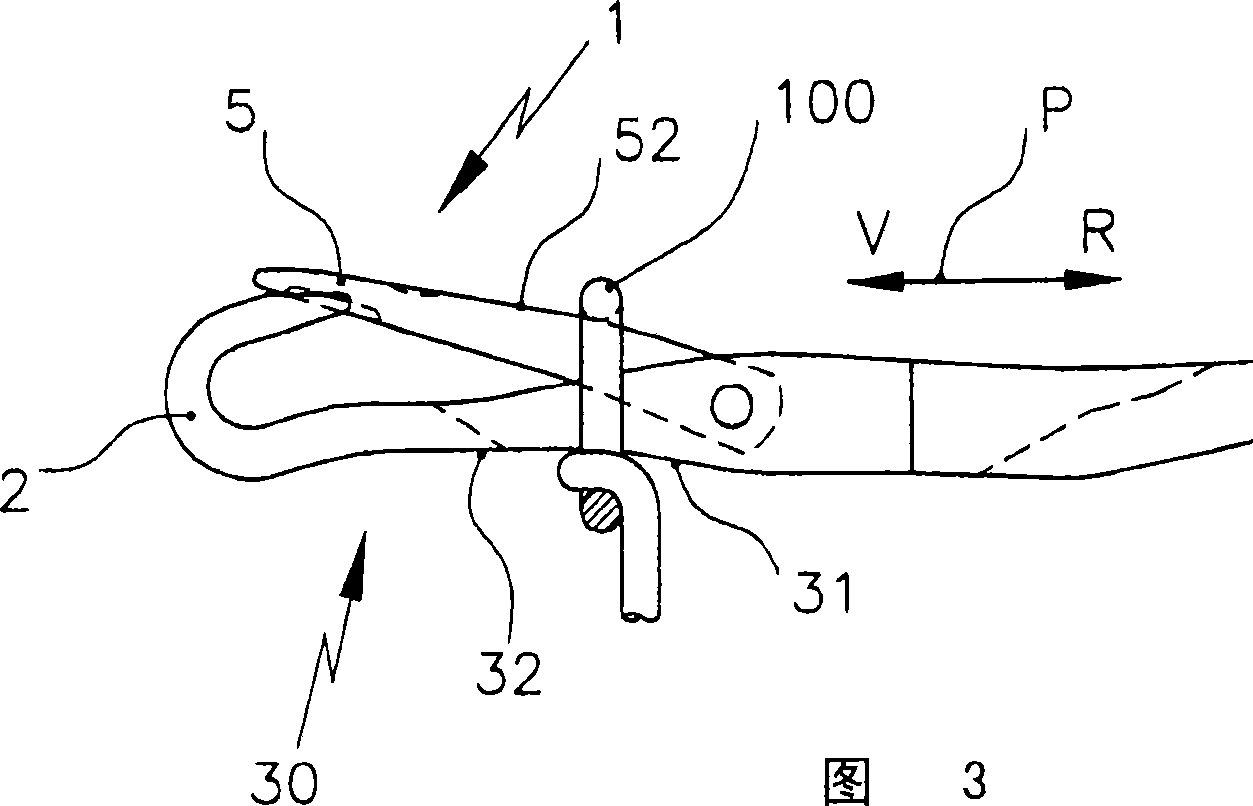

[0018] The latch needle 1 shown in FIGS. 1 to 5 has a hook 2 which encloses a hook space 20 . The needle hook 2 is molded onto the needle neck 3 , which transitions via the needle breast 4 into the needle shaft 6 . On the needle bar 6 , the latch 5 is mounted pivotably in the latch needle groove 60 at the articulation point 50 . The needle latch 5 can be brought from the open position shown in FIG. 1 into the closed position shown in FIGS. 2 to 5 by means of the coil 100 . Other positions of the latch 5, such as a half-open or half-closed position, can be achieved by means of a latch spring not shown here.

[0019] On the underside of the needle shank 6 in the region of the needle neck 3 there is provided a recess 30 which reduces stress on the coil. This recess 30 starts in the region of the articulation point 50 of the needle latch 5 and extends to the underside of the needle hook 2 .

[0020] In the region of the articulation point 50 , the recess 30 has a first inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com