Interlocked changeover switch

A transfer switch and interlocking technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve problems such as difficult loop mechanical interlocking, difficult installation and maintenance, and complicated electrical structure, so as to improve the quality of power supply and the safety of power supply , The effect of simplifying the primary loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

[0022] An interlock transfer switch, comprising N circuit switches, N actuators and a mechanical interlock mechanism, where N is a positive integer.

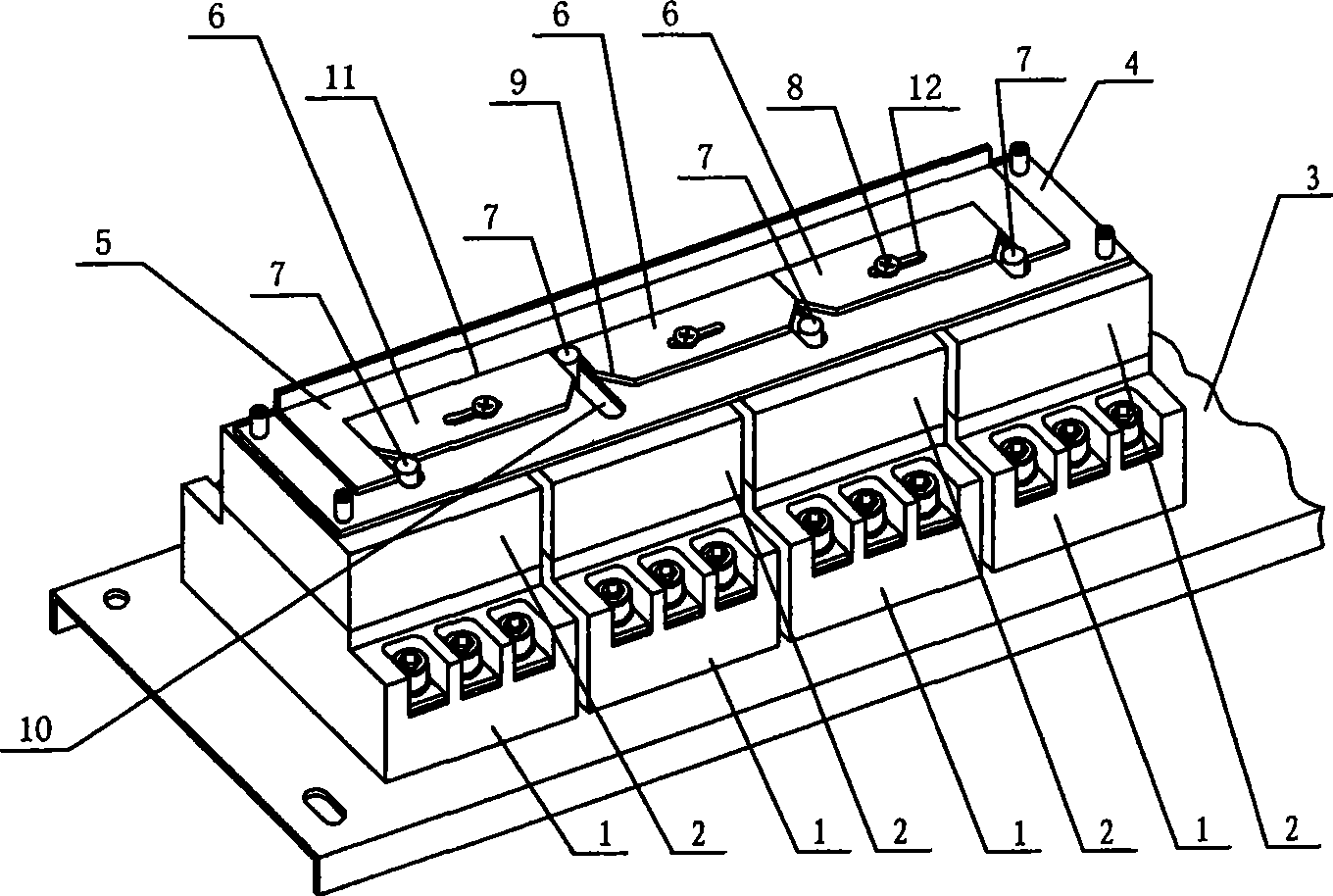

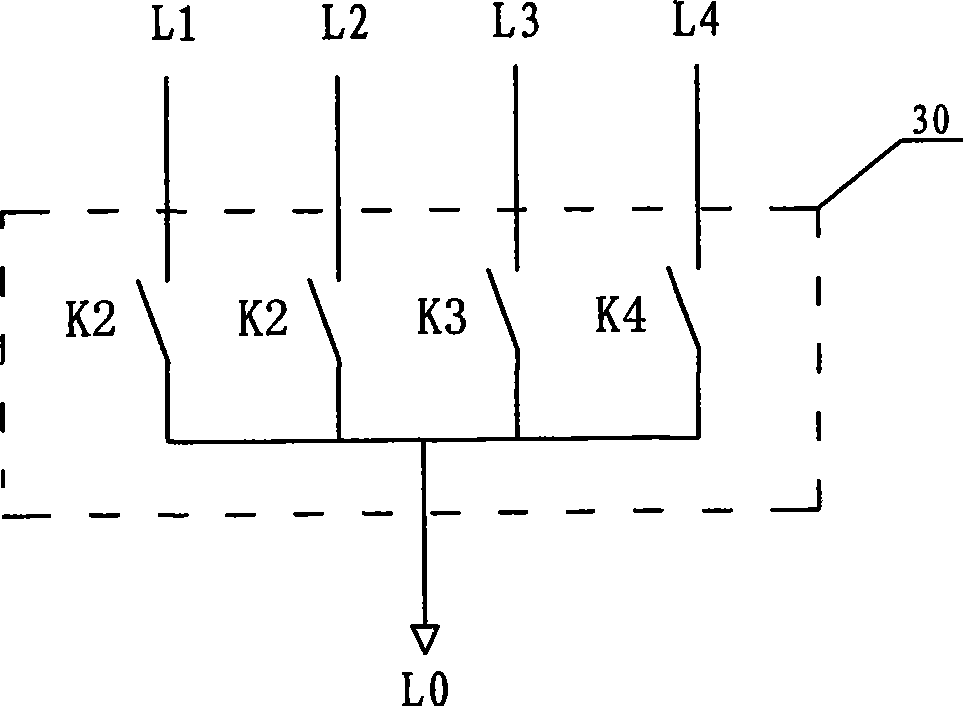

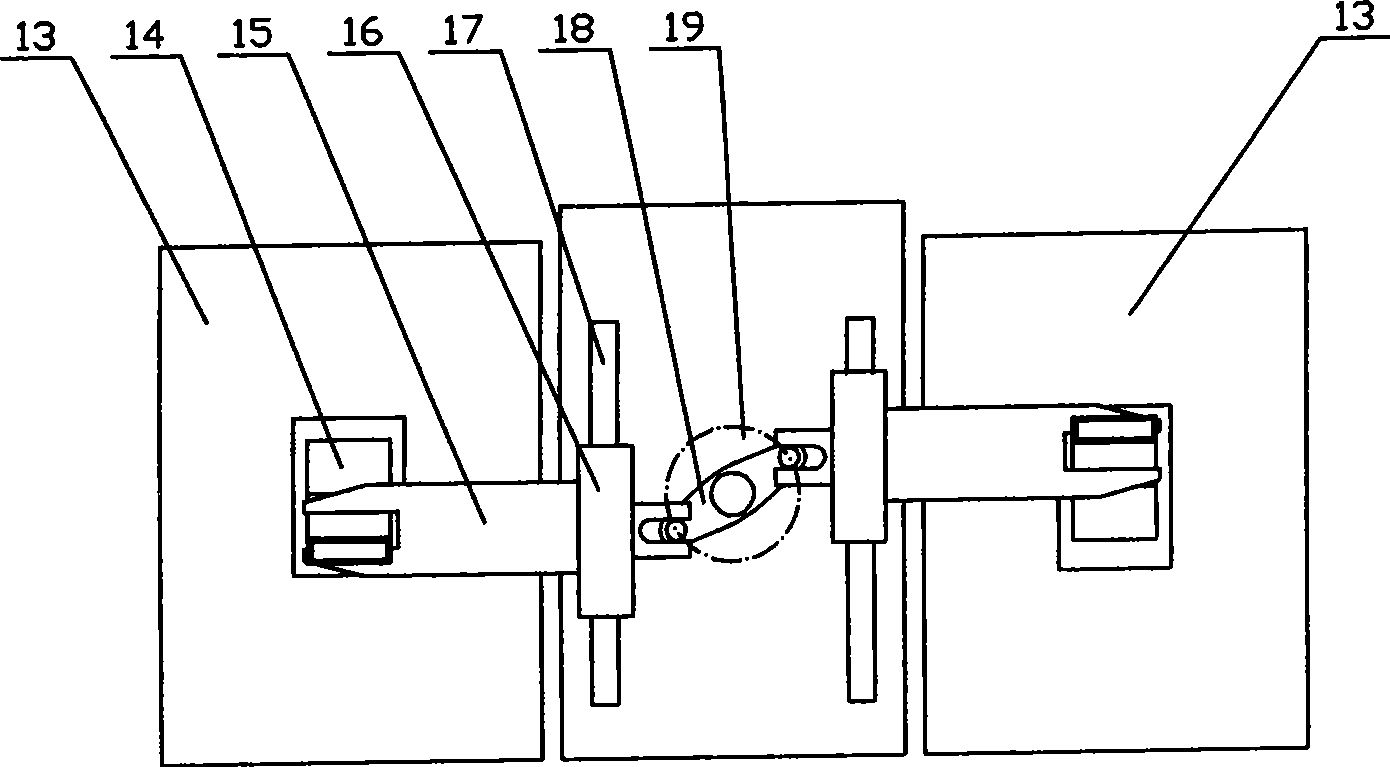

[0023] This embodiment is a four-circuit interlocking changeover switch, and its structure is shown in the attached figure 1 , it consists of 4 circuit switches 1 concentrated and installed horizontally and side by side on the bottom plate 3, each circuit switch 1 is stacked with an actuator 2, and the 4 actuators 2 are connected through a common mechanical interlock mechanism; mechanical interlock The mechanism is composed of three limit blocks 6 that slide left and right in parallel on the guide rail 4. The long plate-shaped guide rail 4 is transversely connected to the panels of the four actuators 2, and the guide rail 4 corresponds to each actuator. 2 There is a longitudinal bar hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com