Swing bridge for converting a rotary motion into an oscillating motion and use of same in an electrical device

A technology of rotating motion and oscillating motion, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of collision between the drive device and the vibration bridge, and increase the noise level, so as to achieve reduced complexity, good manufacturing tolerance, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

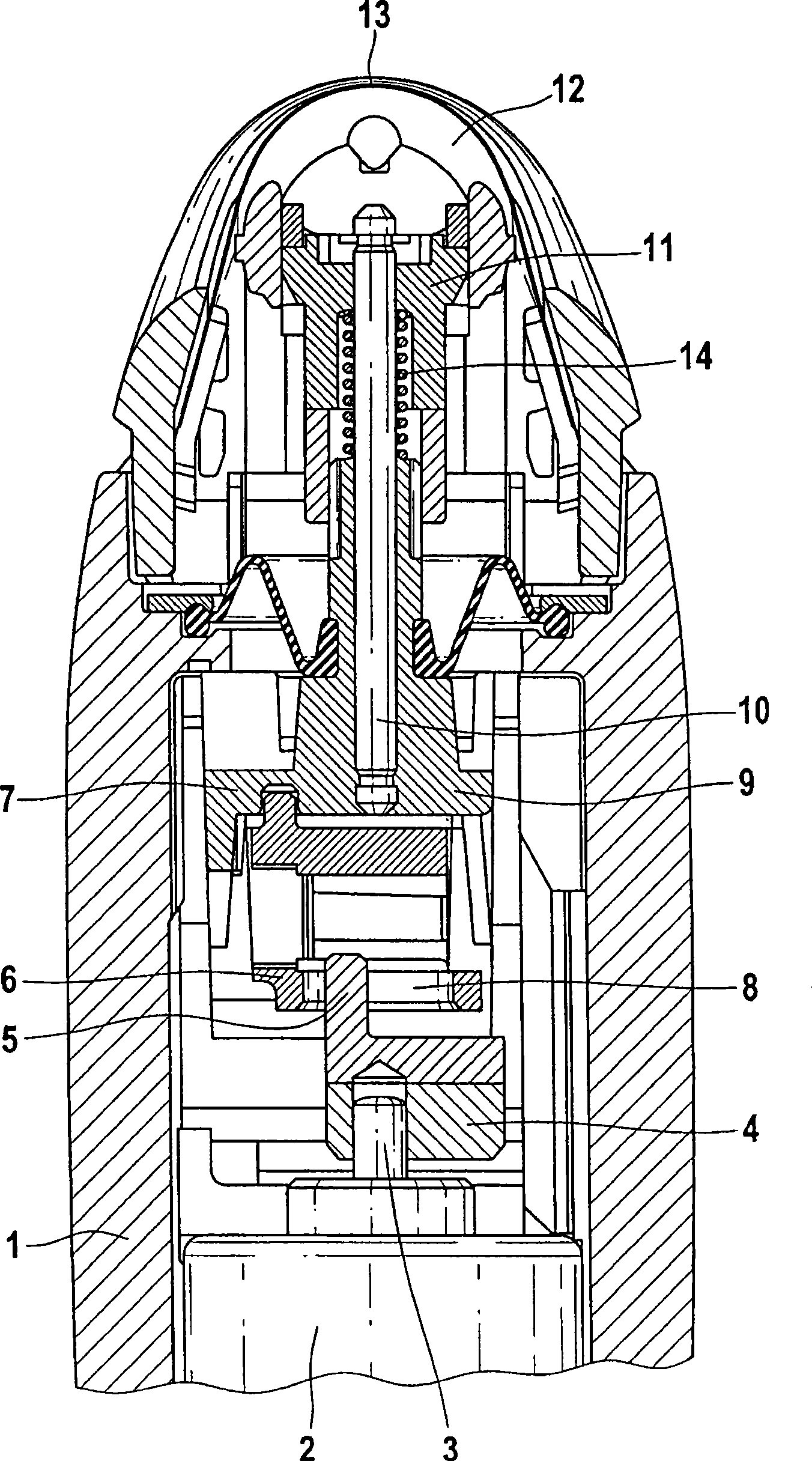

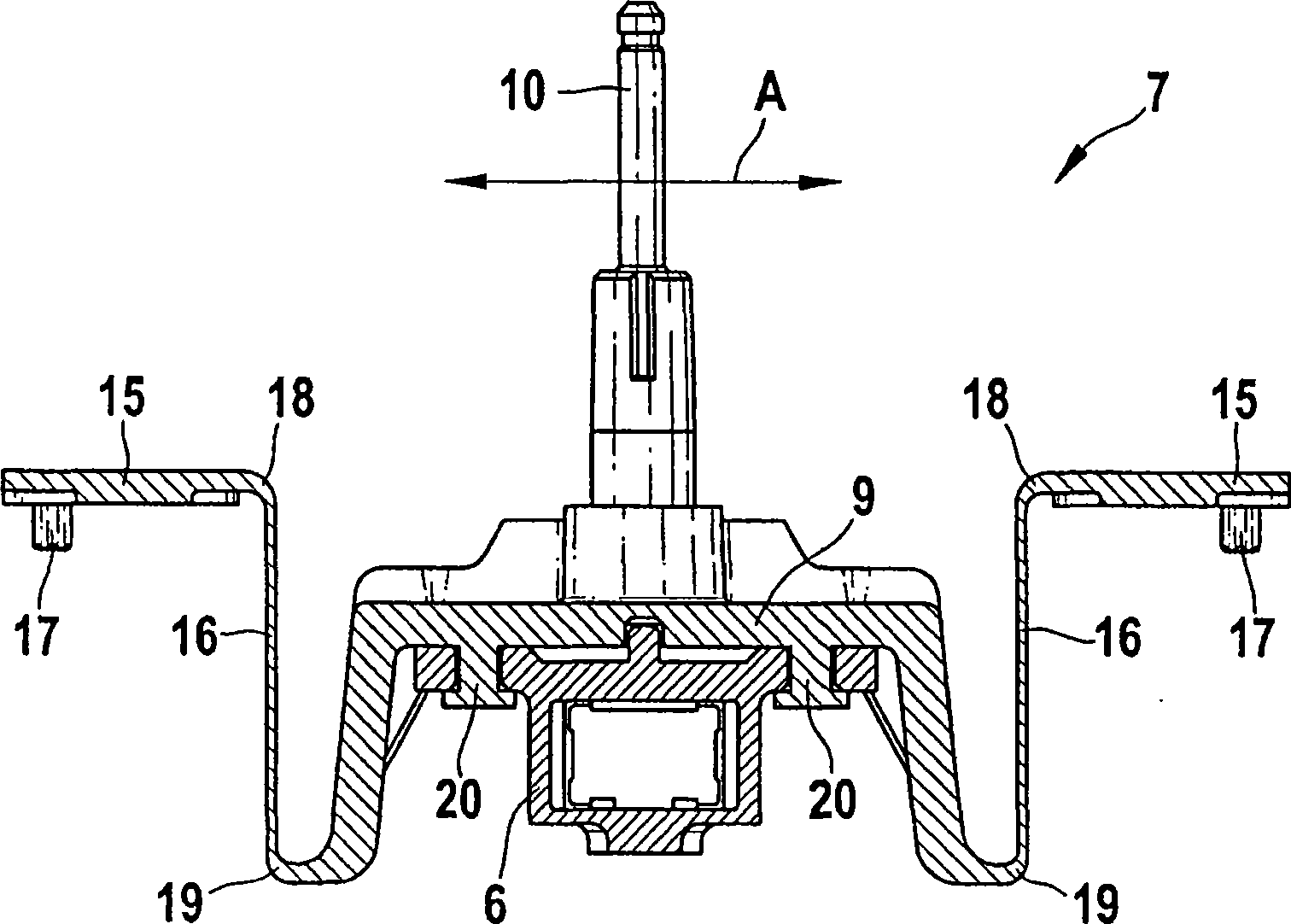

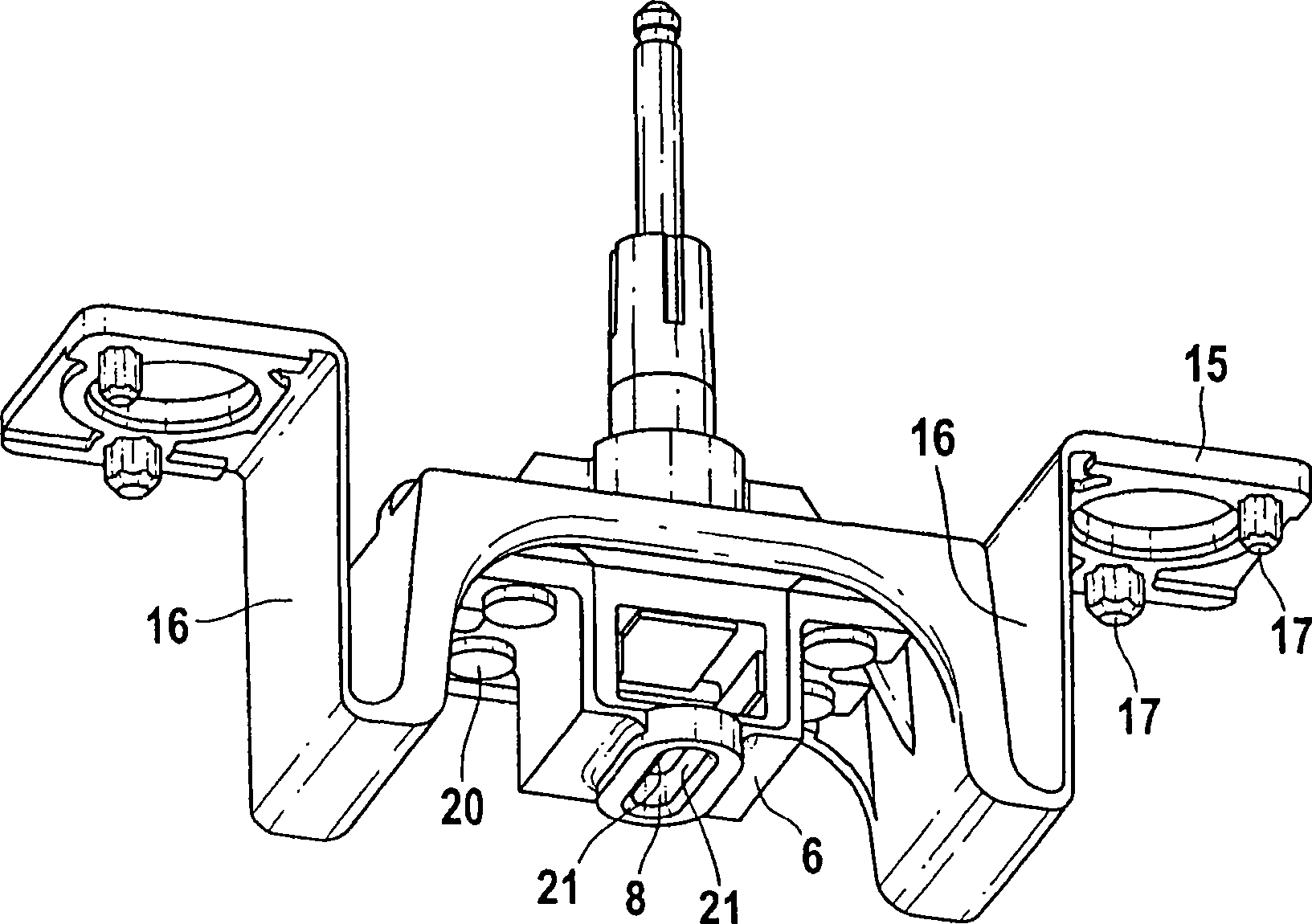

[0015] exist figure 1 The dry shaving apparatus shown in has a housing 1 in which an electric motor 2 with a drive shaft 3 is fastened. Mounted on the drive shaft 3 is an eccentric part 4 , which is connected to the drive shaft 3 in a rotationally fixed and at the same time fixed manner in the axial direction. The eccentric part 4 has a pin 5 offset eccentrically relative to the drive shaft 3 , which engages in a coupling part 6 of a vibrating bridge 7 . For this purpose, the coupling part 6 has an opening 8 extending horizontally in the plane of the drawing, the width of which corresponds to the diameter of the pin 5 .

[0016] As soon as the drive shaft 3 of the electric motor 2 is driven in rotation, an oscillating movement is produced by the vibrating bridge, the direction of which is perpendicular to the plane of the drawing. The oscillating body 9 is provided in its upper region with a bearing pin on which the lower knife 11 of the shearing system is held. In a known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com