Method and apparatus for manufacturing color filter

A manufacturing method and a manufacturing device technology, which are applied in the field of color filter manufacturing and its devices, can solve the problems of inability to coat, increase the possibility of defective products, and increase the overall cost, and achieve the effect of suppressing uneven color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

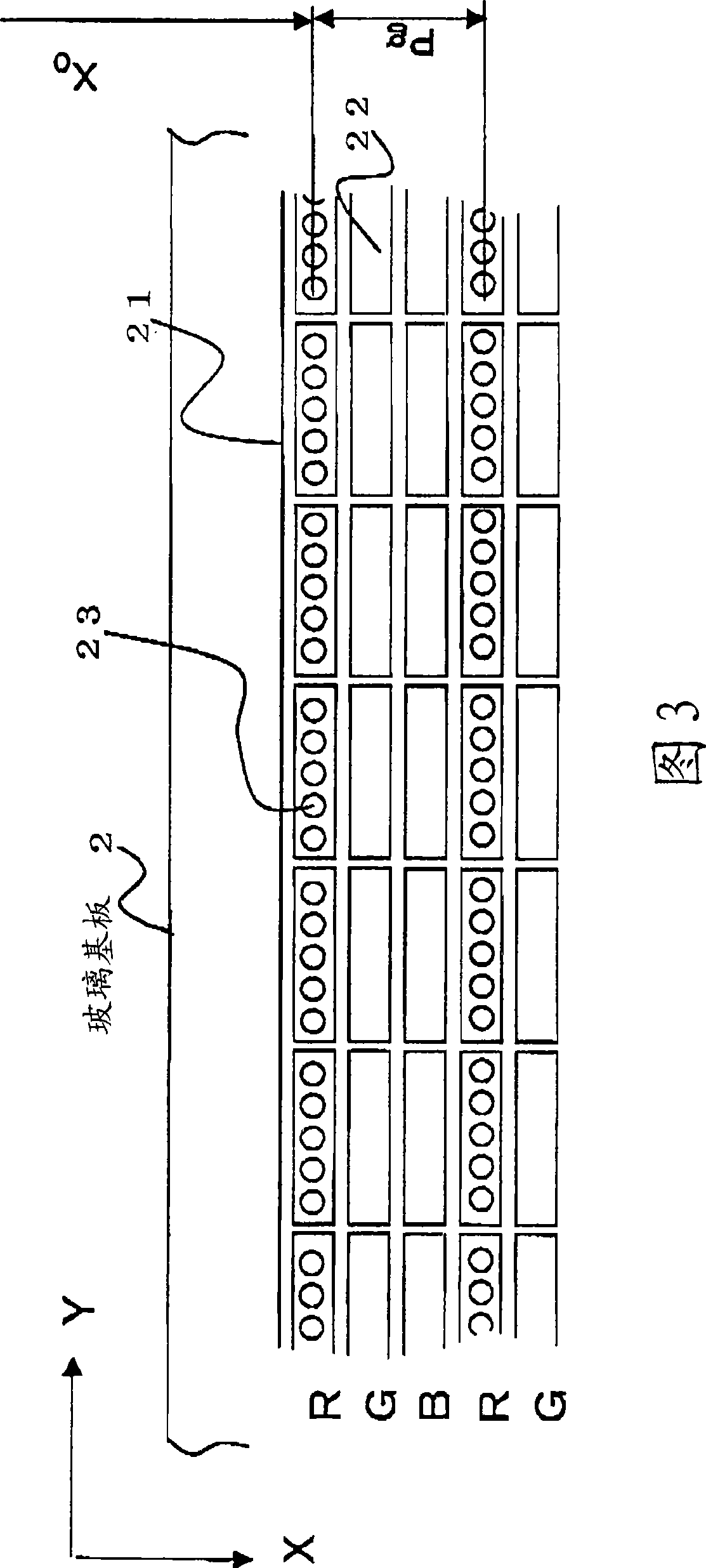

[0103] The nozzle width is 25400μm, the nozzle resolution is 1440dpi, the nozzle pitch P is 25400 / 1440=17.6μm, the pixel size is a=300μm, b=100μm, the coating area size is c=220μm, d=20μm, relative to the nozzle The number is N=c / P=220 / 17.6 12. The coating test was carried out under the conditions that the number M of droplets in the relative moving direction was 1, the coating amount in a pixel (filling amount in a pixel) V was 300p1, and the average Q of one droplet was 40p1.

[0104] Under this condition, the number n of remaining nozzles that satisfies the application amount in a pixel can be obtained by substituting a specific numerical value into Equation 1, and the number n of remaining nozzles is 4 or less.

[0105] As a result, the number i of combinations of ink jet nozzles 52 was 495.

[0106] Therefore, by using the ink nozzles 52 of 495 or less combinations (for example, 50 combinations) (for example, 50 combinations) (selection of the discharge state) to apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com