Method and apparatus for strain monitoring of printed circuit board assemblies

A printed circuit board, circuit board technology, applied in the direction of printed circuit stress/deformation reduction, printed circuit components, printed circuits, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

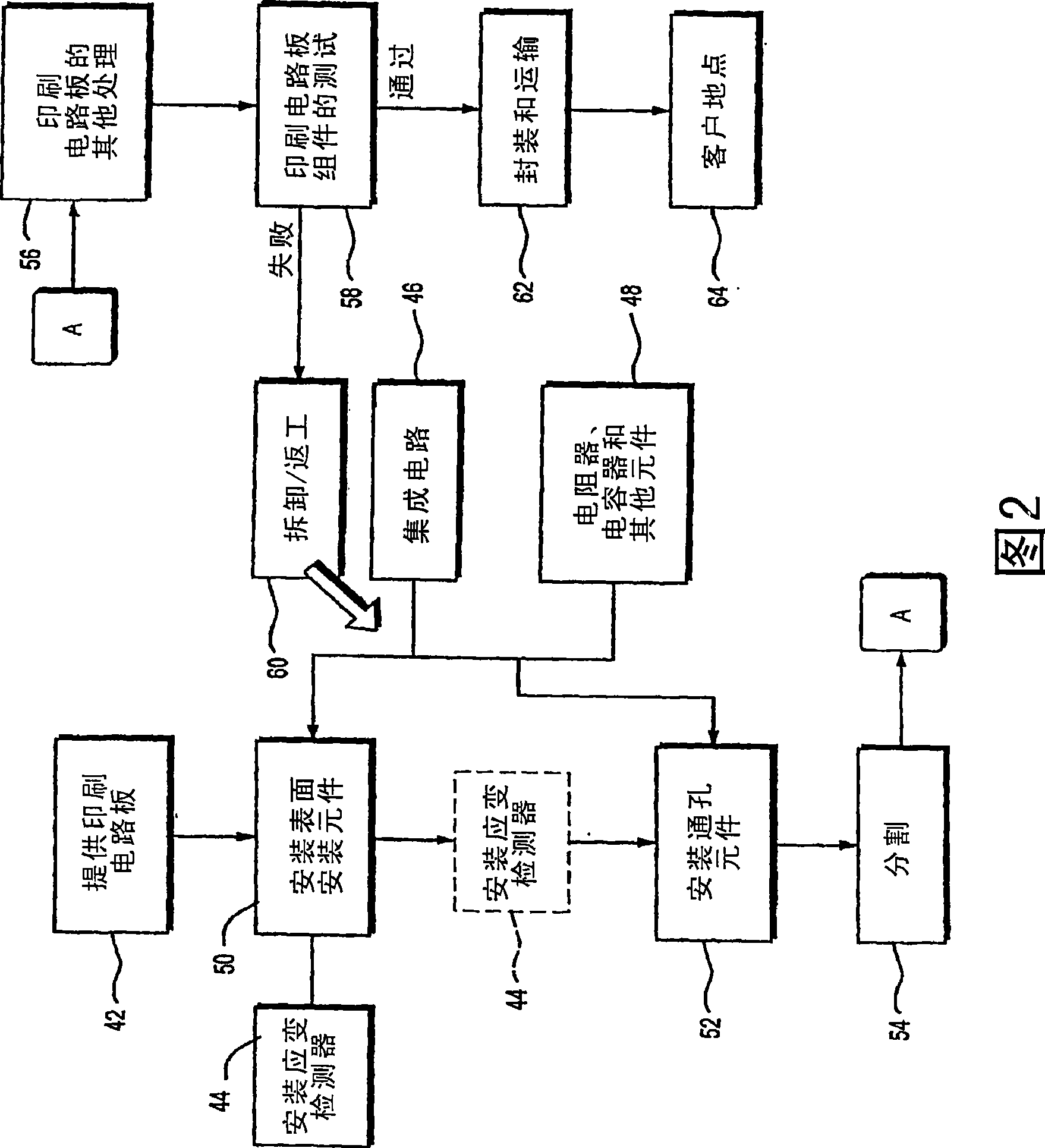

[0025] An improved method of testing / monitoring a printed circuit board assembly (PCBA) for strain-induced failure utilizes at least one strain detector mounted on the printed circuit board, wherein the strain detector is formed from a non-ductile material . The strain detector has a narrow section in order to limit the weakest link of failure to a predetermined strain range. Malfunction of the strain detector and strain reaching a critical strain range can be determined visually or electrically. Therefore, the traditional method of using strain gages with associated costs and limited to sampling the PCBA is unnecessary.

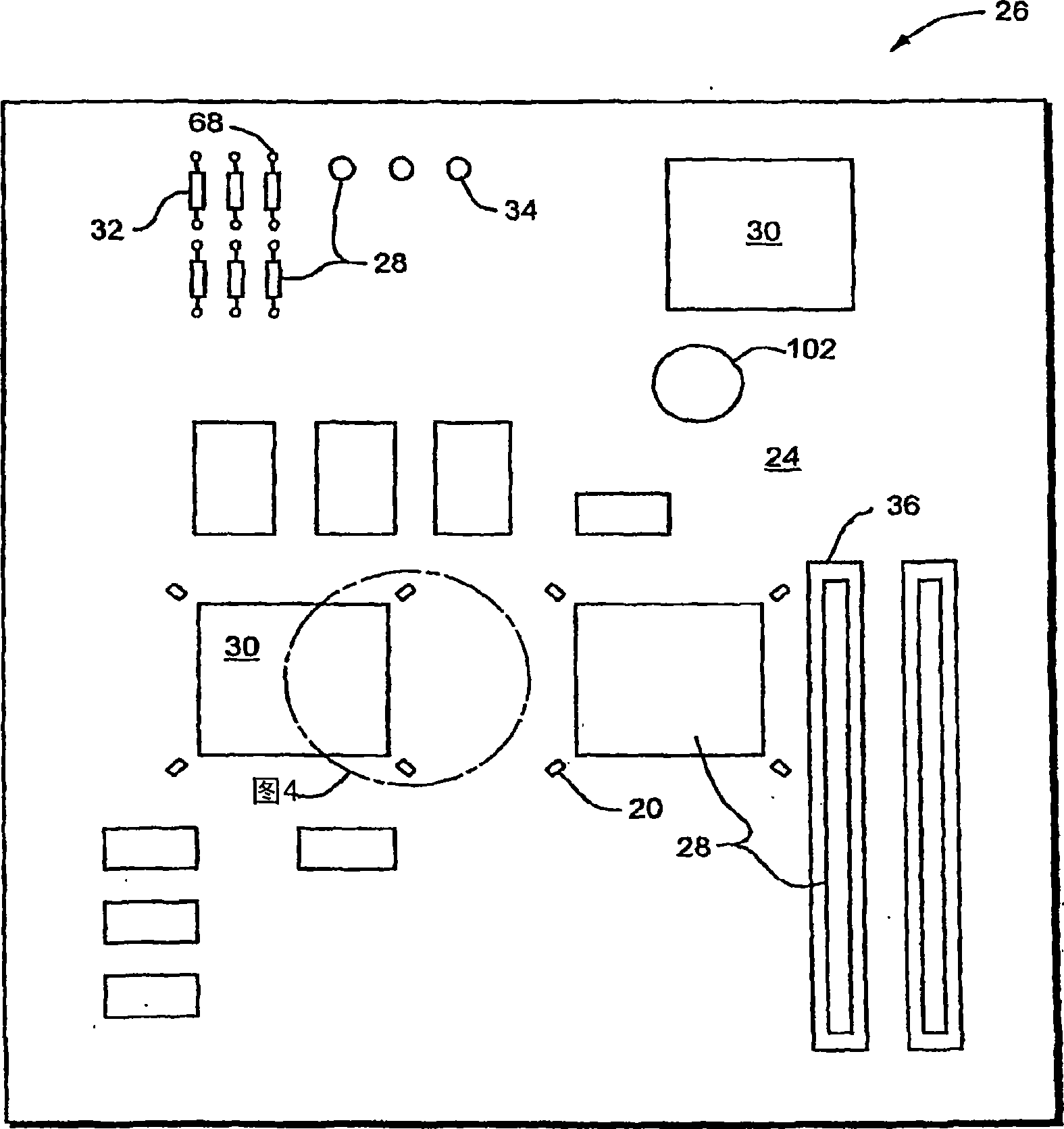

[0026] When referring to the drawings in the ensuing description, like numerals indicate like elements. figure 1 Strain detector 20 is shown positioned on printed circuit board (PCB) 24 of printed circuit board assembly (PCBA) 26 .

[0027] refer to figure 1 , a printed circuit board assembly (PCBA) is shown. The PCBA 26 has a series of components 28 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com