Lotus leaf basin and method for producing the same

A production method and technology of lotus leaves, which can be applied to botanical equipment and methods, clay products, and other household utensils, etc., can solve the problems of not being realistic enough, not beautiful enough, affecting the appearance, etc., and achieve the effect of preventing breakage and water leakage and enhancing the aesthetic feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

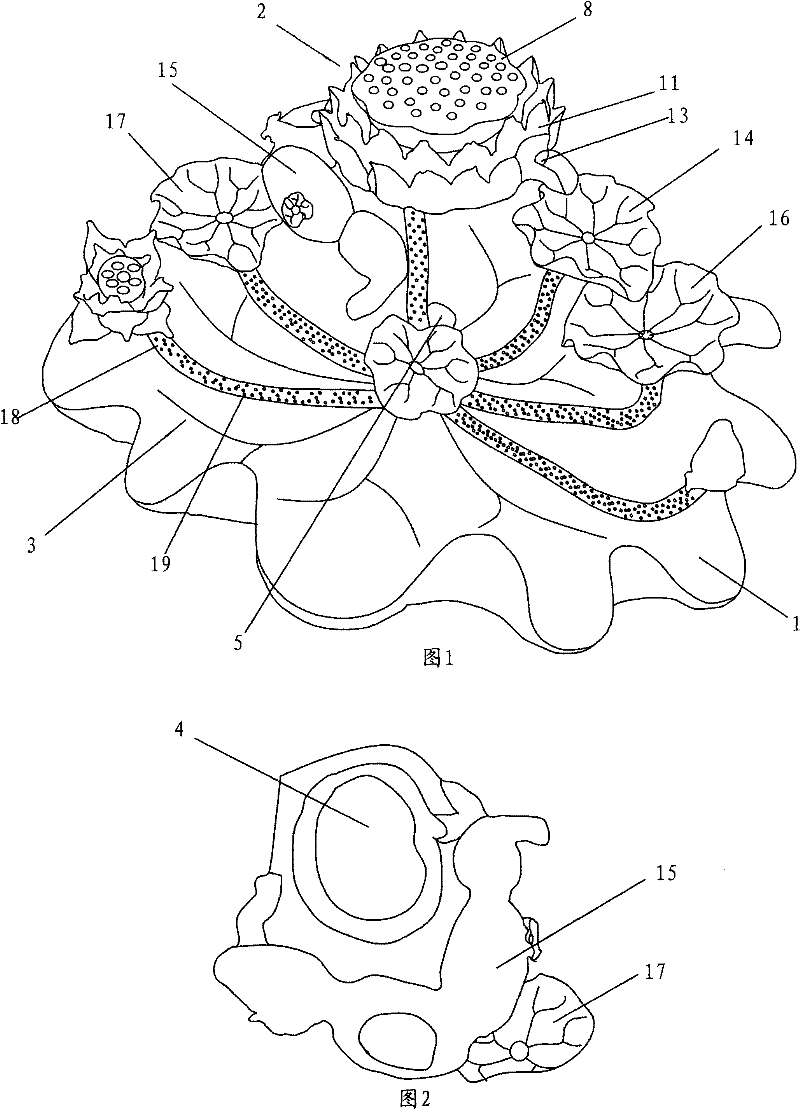

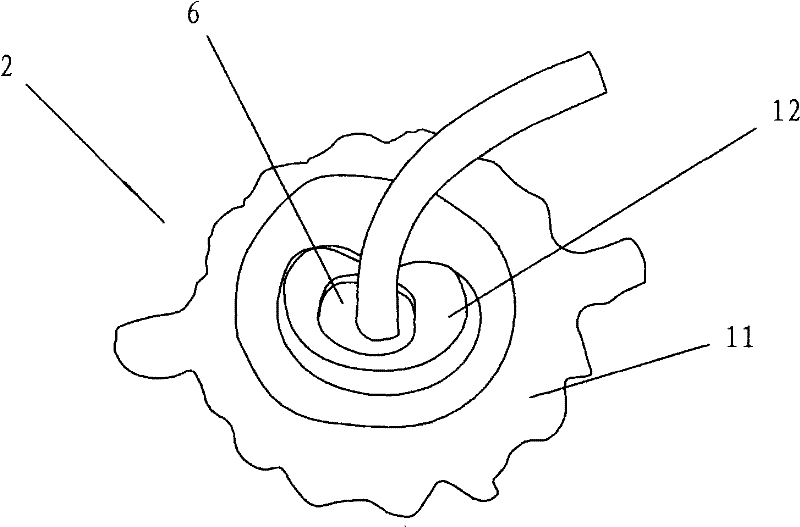

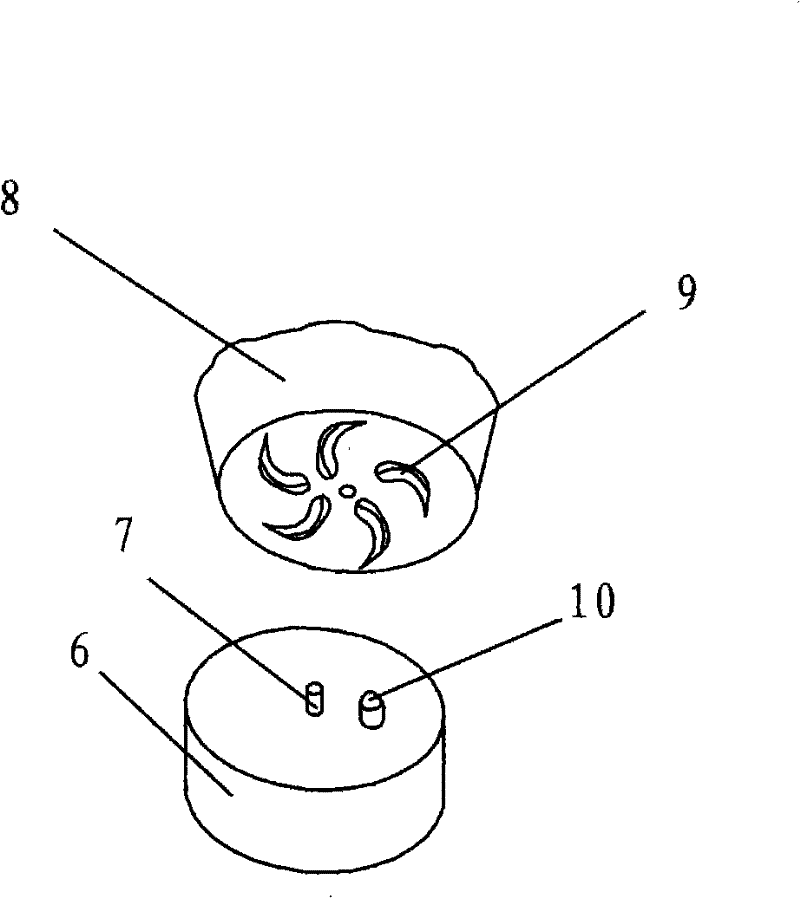

[0024] refer to Figure 1 to Figure 4 , a lotus leaf pot, comprising a pot body 1, a water pump and a rotating device 2 forced to rotate by water pressure are arranged in the pot body 1, and a raised leaf pattern 3 is provided on the inner and outer surfaces of the pot body 1, thereby ensuring The lotus leaf basin of the present invention has a lifelike shape; and the water pump is installed in the inner hole 4 of the basin body 1, and the rotating device 2 is installed on the top of the inner hole 4, and the bottom of the inner hole 4 is provided with a hole communicating with the basin body 1. Through hole 5, water pump just can hide like this, prevents water pump from affecting the outward appearance of lotus leaf basin. Wherein, the rotating device 2 includes a fixed base 6, the fixed base 6 is connected with a rotating base 8 through a connecting shaft 7, the bottom surface of the rotating base 8 is provided with a water guide groove 9, and the fixed base 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com