Structure of permutation and combination type windshield wiper

A combined, wiper technology, used in vehicle cleaning, vehicle maintenance, transportation and packaging, can solve problems such as increased costs, a large number of other related exclusive parts, and the inability to apply all in one, so as to improve market competitiveness and reduce costs. Production cost, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

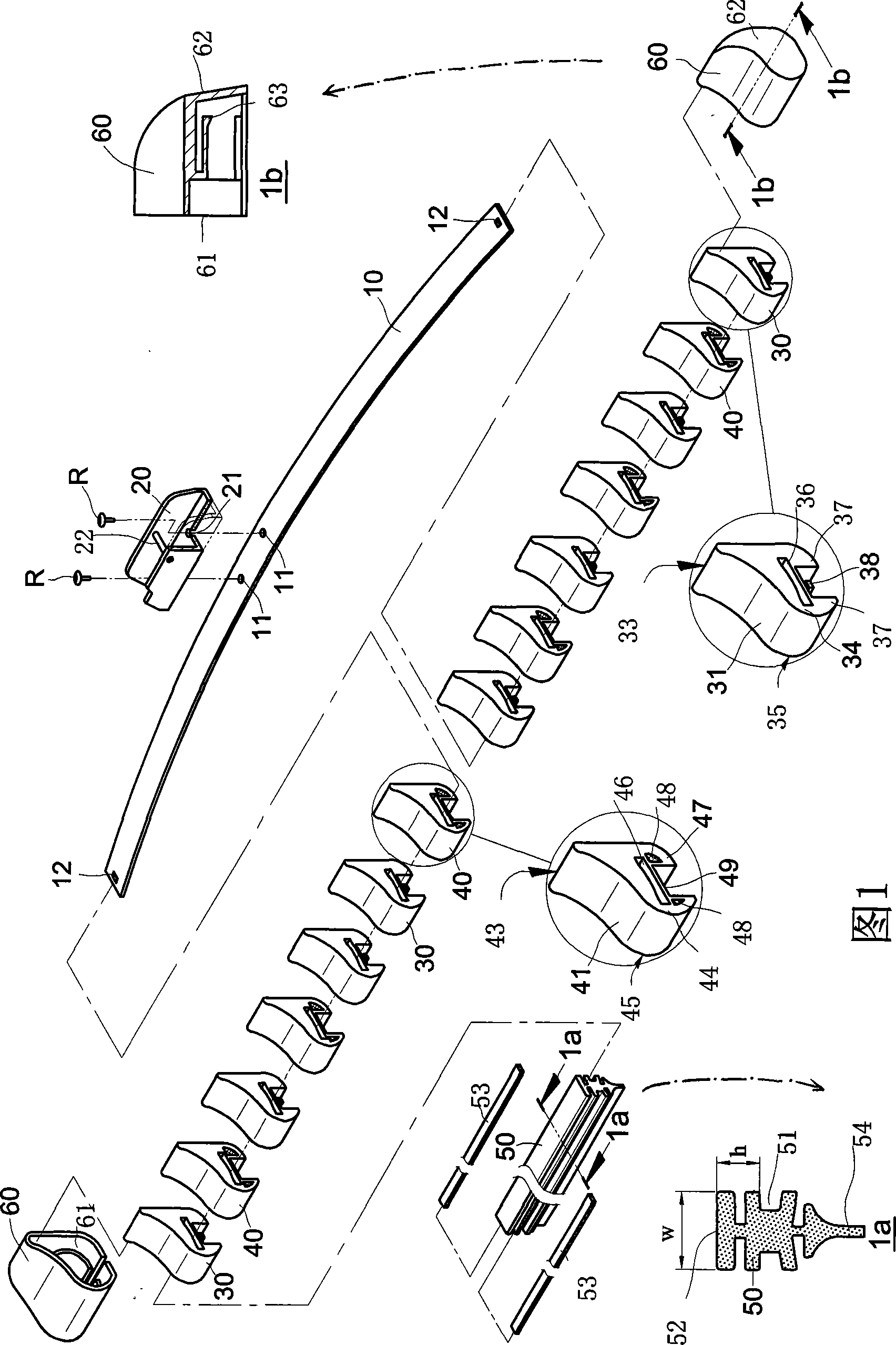

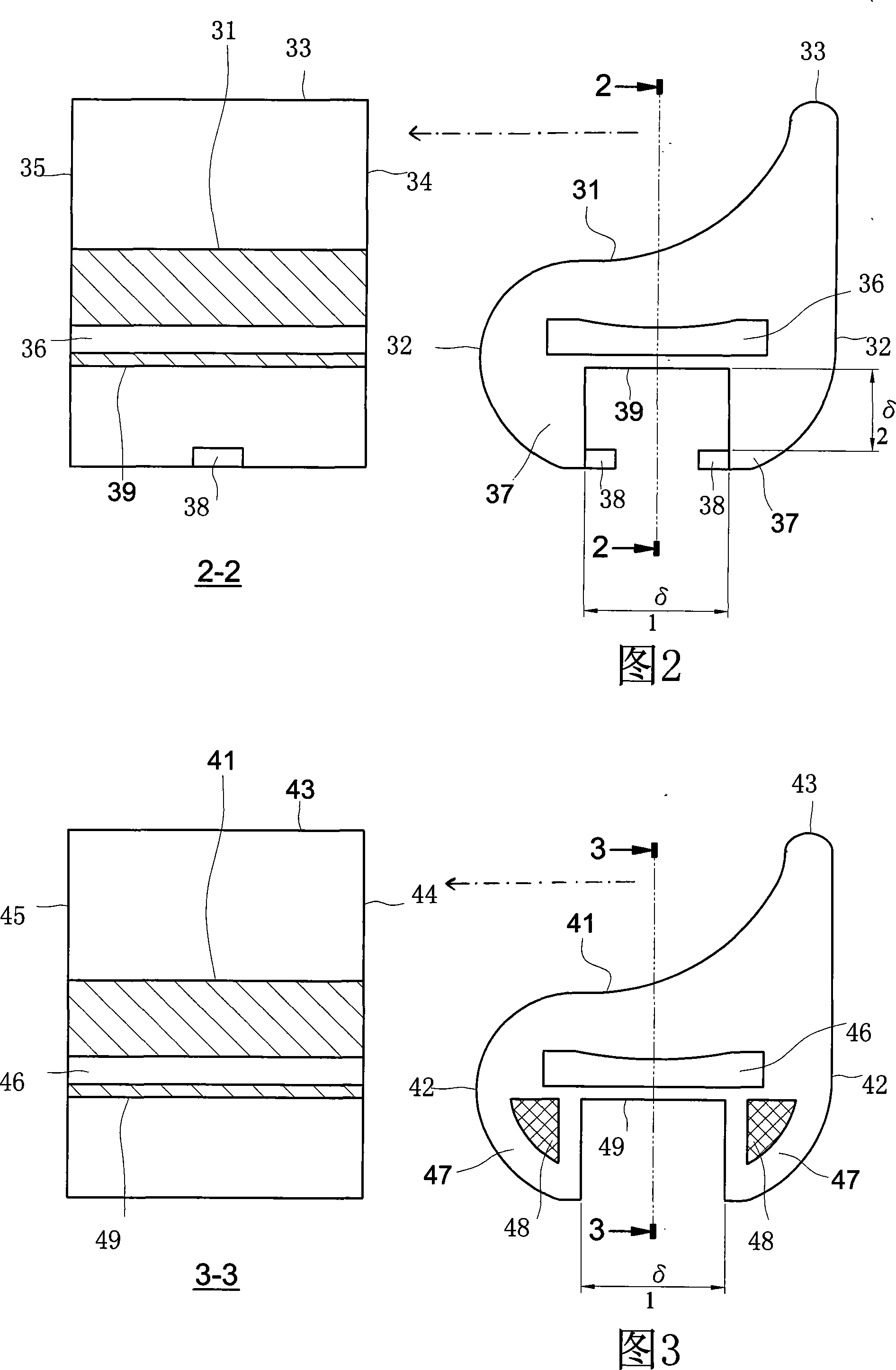

[0054] The structure of an arrangement and combination wiper of the present invention, please refer to Figure 1 to Figure 3 and Figure 12, Figure 13 shown, which includes:

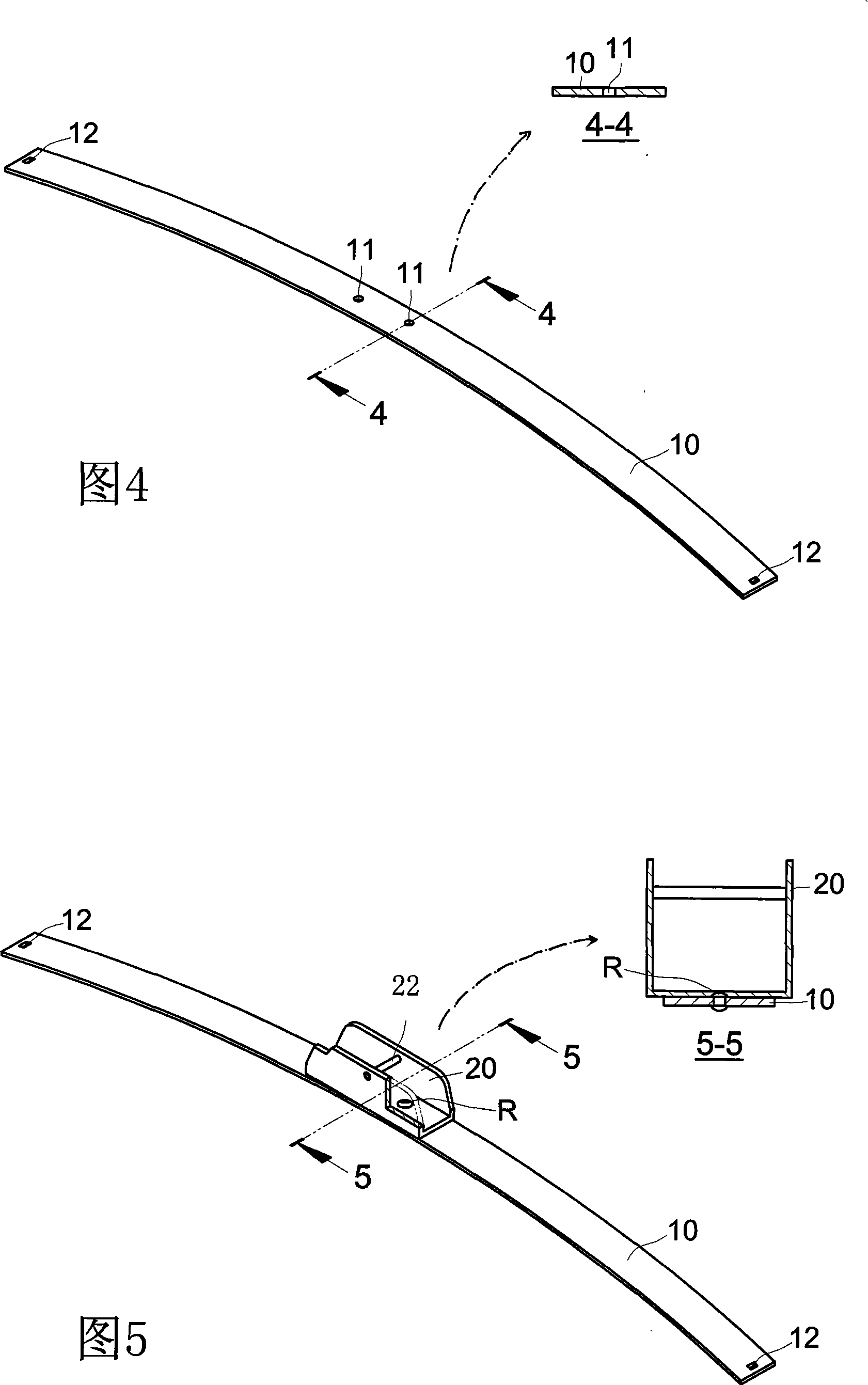

[0055] A flexible curved shrapnel 10 is made of metal material and is a long, flat plate-shaped body that bends downward. A pair of riveting holes 11 are pierced in the center of the board surface, and a pair of riveting holes 11 are pierced on the board surface near the ends of the two short sides. Fitting hole 12;

[0056] A support seat 20 is a U-shaped body stamped and formed by metal material. Two through holes 21 corresponding to the pair of riveting holes 11 on the flexible curved spring body 10 are pierced in the center of the bottom surface. The support shaft 22 can be fitted and fixed by a connector 90 (as shown in FIG. 12 ), and is fixed on the end of the wiper rocker arm S (as shown in FIG. 12 ). Figure 13 shown);

[0057] A plurality of bearing blocks 30 are arranged and sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com