Tension stabilizing device for band steel in continuous annealing wire annealing furnace

A technology for stabilizing devices and annealing furnaces, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of strip steel scrapping, loss of furnace shutdown, and easy-to-break strips, and achieve the effect of simple structure and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

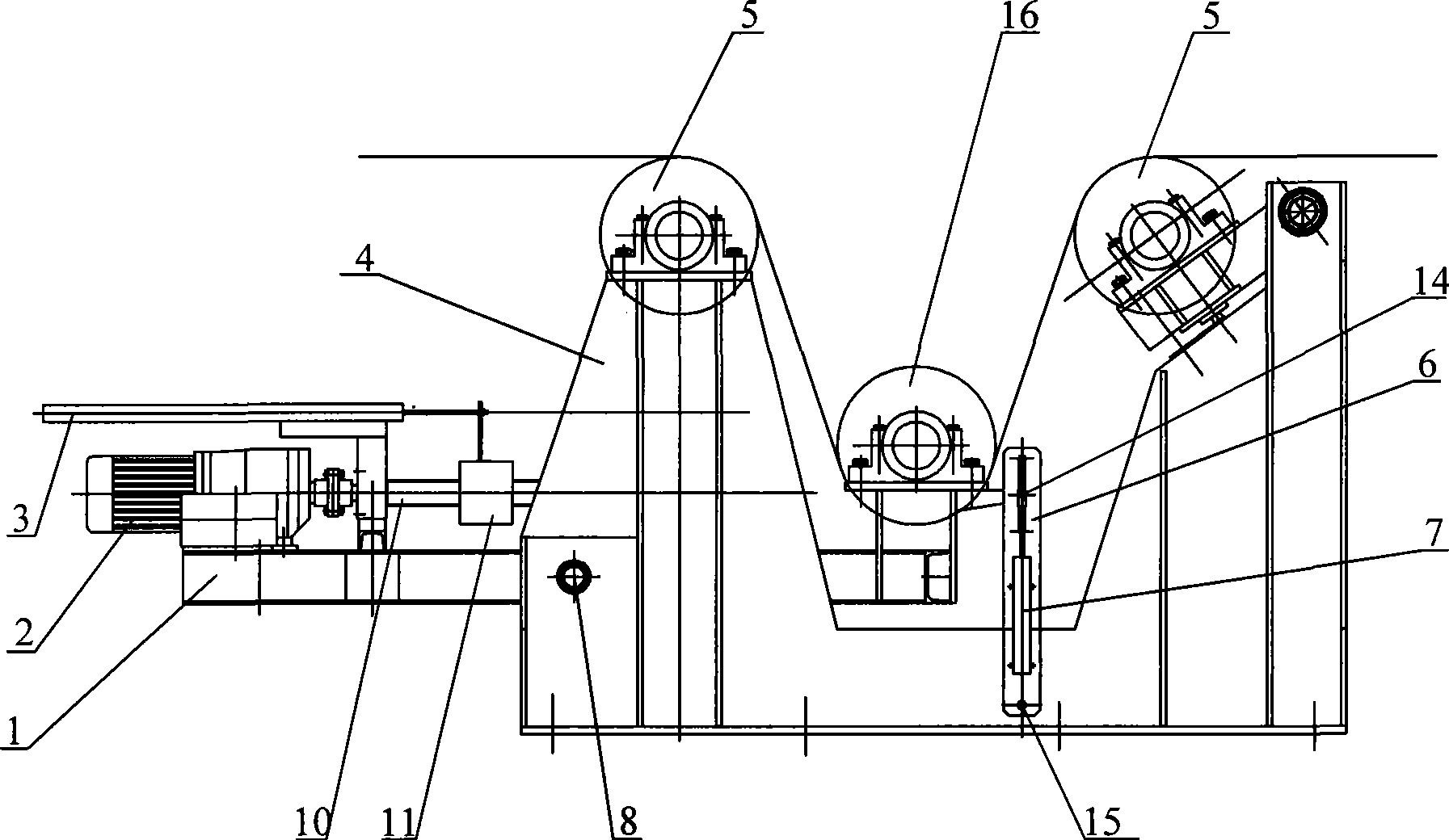

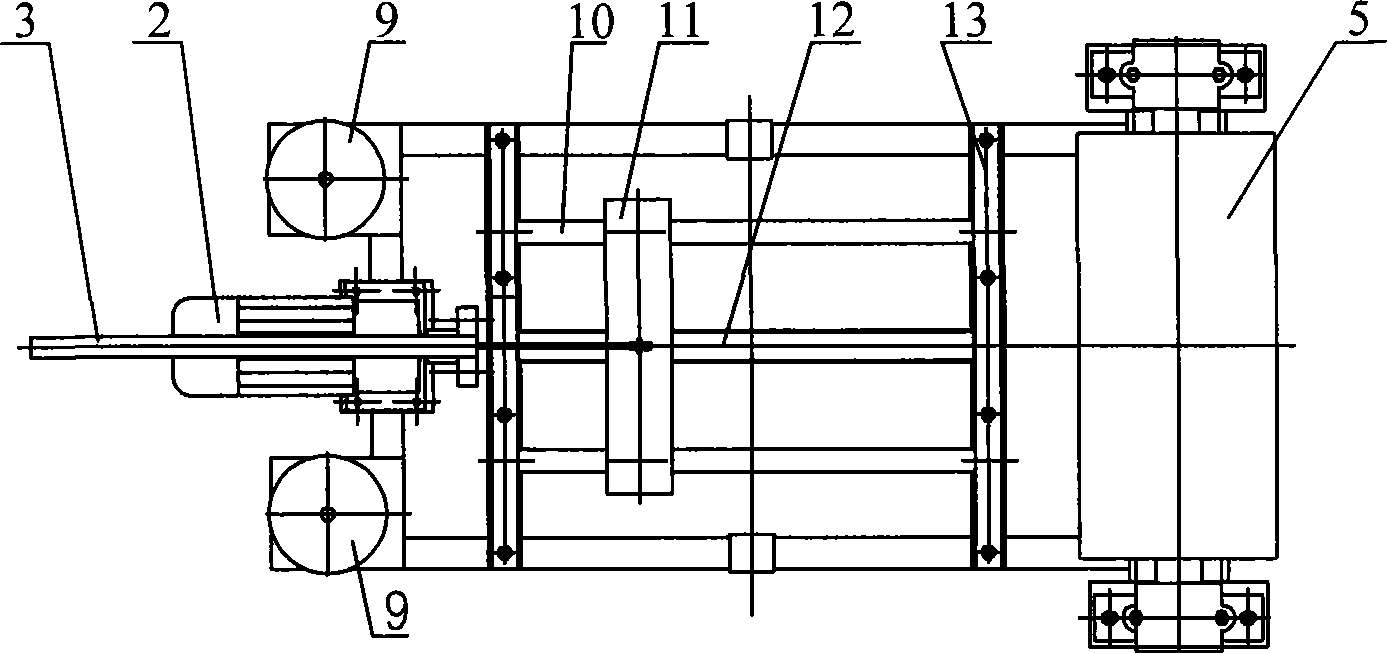

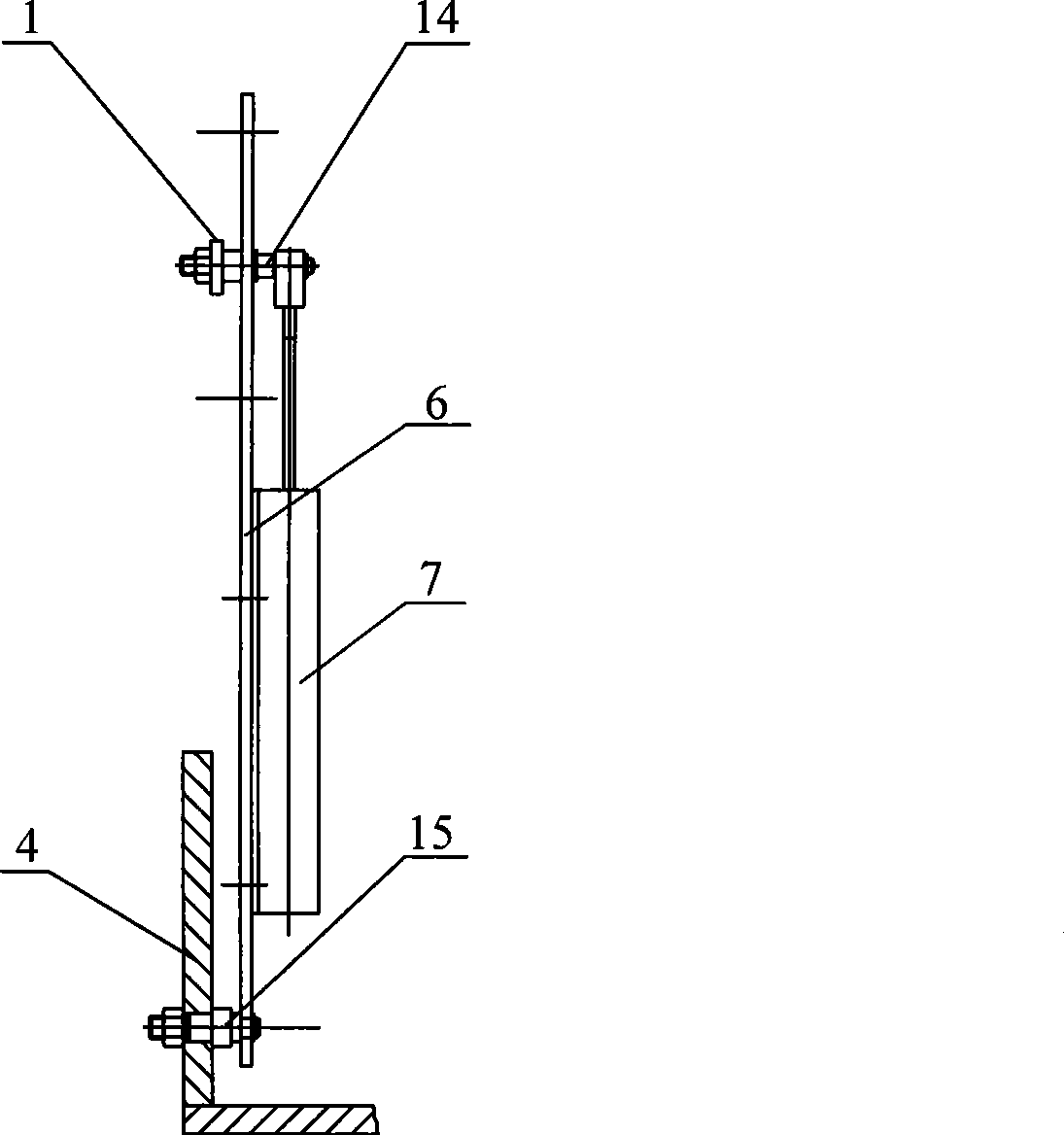

[0011] As shown in the figure: the present invention mainly consists of a swing frame 1, a motor 2 and its reducer, a horizontal displacement sensor 3, a base 4, a fixed steering roller 5, a guide plate 6, a vertical displacement sensor 7, a shaft 8, a counterweight device 9, Guide rod 10, slide block 11, adjusting screw rod 12, bearing block 13, upper fixed shaft 14, lower fixed shaft 15 and elevating guide roller 16 etc. constitute.

[0012] The steel strip tension stabilization device in the annealing furnace of the stainless steel thin strip continuous annealing line includes a fixed base 4, on which a swing frame 1 is hinged through a shaft 8, and on the base 4 there are two fixed turning rollers arranged at intervals 5. The motor 2 and its reducer are fixedly installed on the swing frame 1 at the outer end of the base 4. Bearing seats 13 arranged at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com