Method for testing flame retardancy of titanium fire flame-retardant coating

A technology of flame retardant coating and flame retardant performance, which is used in the field of flame retardant performance testing of titanium-resistant flame retardant coatings, which can solve the problems of slow development of flame retardant performance evaluation and verification technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

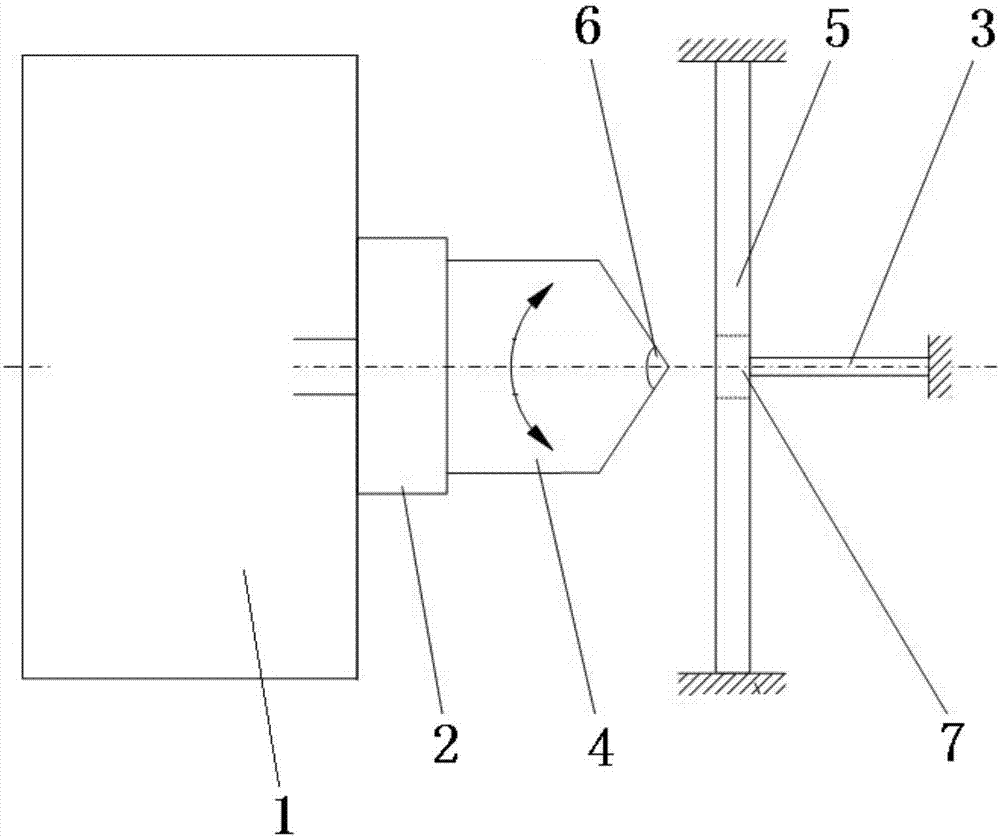

[0022] In conjunction with the accompanying drawings, a method for testing the flame retardant properties of anti-titanium fire flame retardant coatings is specifically provided, including air supply systems, pushing equipment, rotating equipment, timers, fixing devices, dynamic friction blocks and static friction blocks; dynamic friction blocks and static friction blocks They are all titanium alloys with the same material, and the outer surface of the titanium alloy is coated with an anti-titanium fire and flame-retardant coating; there are multiple dynamic friction blocks, and the size, structure and material are exactly the same; there are multiple static friction blocks, and the size, The structure and material are exactly the same;

[0023] The dynamic friction block is fixedly installed on the rotating equipment, driven and rotated by the rotating equipment; the dynamic friction block is wedge-shaped, and the center line of the wedge is the rotation center line of the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com