Secondary vaporizing integral electric steam iron

An electric iron, integrated technology, applied in the field of ironing appliances, to achieve the effect of low humidity, high steam pressure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

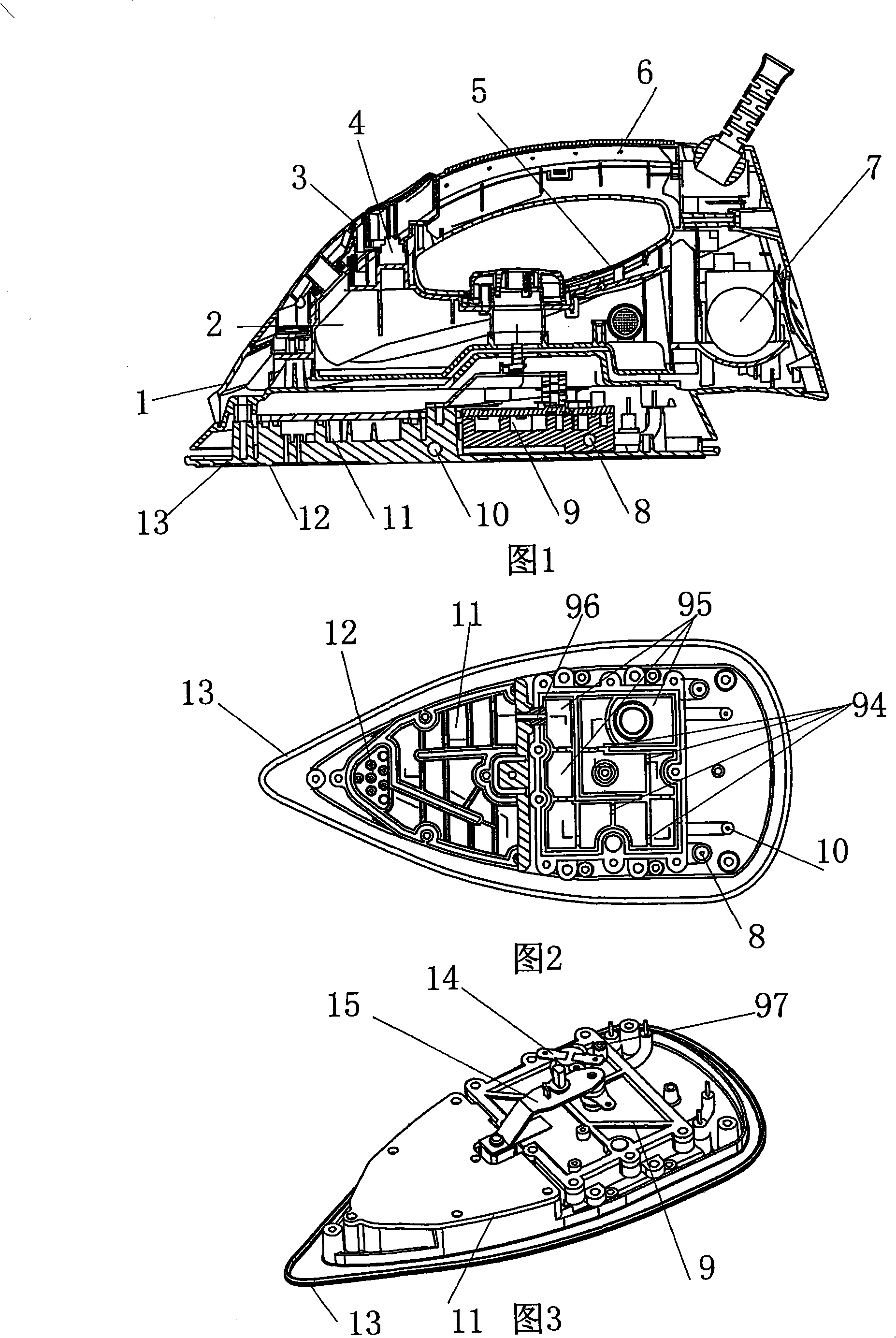

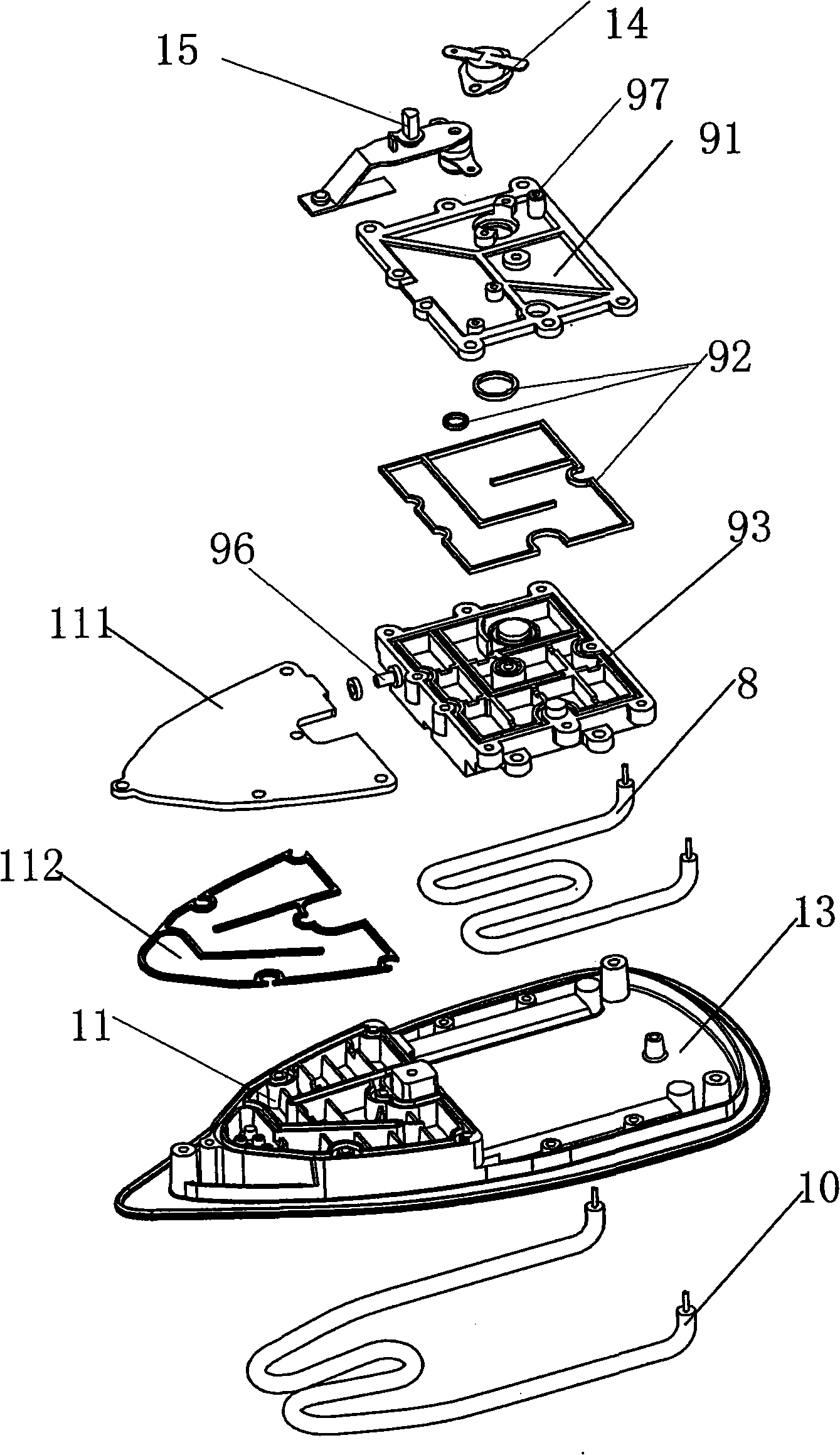

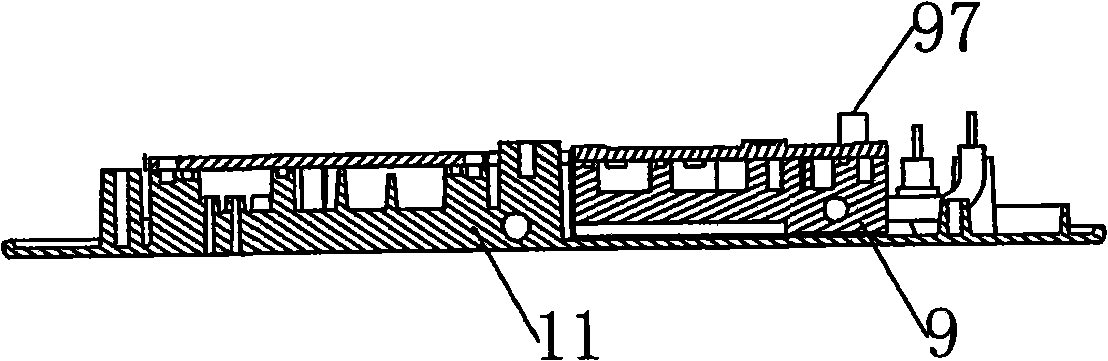

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] As shown in Figures 1, 3, and 4, a secondary vaporization integrated steam electric iron includes a casing 1, a handle 6, a water tank 2, a bottom plate 13, a vaporization chamber 11 on the bottom plate, and an electric heater for heating the bottom plate 13. The heater 10 is characterized in that a vaporizer 9 is also provided on the same plane as the bottom plate at the same height as the vaporization chamber 11 (see Figure 5 ); the water inlet 97 of the vaporizer is connected to the water pump 7 and is closely connected to the water tank 2, and the steam outlet 96 is directly connected to the vaporization chamber 11; the vaporizer 9 is an aluminum die-casting shell (also can be made of zinc, copper One or made of aluminum, zinc, copper alloy materials), there are several steam chambers 95 in the shell, and every two adjacent steam chambers have a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com