Method for generating electricity by using secondary recycling of steel-making converter gas

A secondary recovery and gas technology, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of energy waste, high concentration requirements, insufficient recovery of converter gas, etc., and achieve an increase in recovery volume. , to ensure the effect of stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

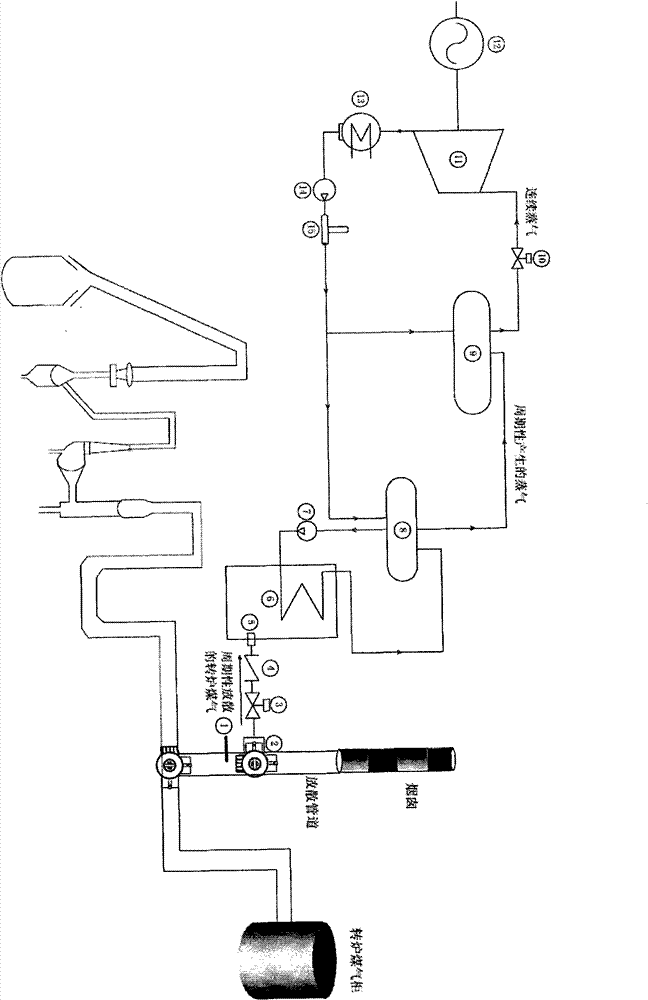

[0017] figure 1 It is a specific embodiment of the present invention.

[0018] The power generation system of the present invention mainly includes a check valve 4, a gas regulating valve 3, a burner 5, a waste heat boiler 6, a heat accumulator 9, a steam regulating valve 10, a steam turbine 11, a generating set 12, a condenser 13, a circulating water pump 14, Deaerator 15 etc. Install three-way valve 2 and calorific value analyzer 1 in front of the chimney. Three-way valve 2 is installed at the connection between the exhaust pipe in front of the chimney and the gas secondary recovery pipe. Calorific value analyzer 1 is installed near the three-way valve 2. At 0.5-1.5 meters in front of the incoming side of the pipeline, the action of the three-way valve 2 is controlled by the calorific value of the gas detected by the calorific value analyzer 1. When the calorific value meets the requirements for the secondary recovery of gas, the three-way valve 2 The recovery side is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com