Assembly method for principal shaft and gearbox of large aerogenerator

A wind turbine and assembly method technology, applied in the assembly of wind turbines, wind turbine components, wind turbines, etc., can solve the problems of reduced assembly work efficiency, high risk of overturning, increased risk, etc., to achieve the benefit of mass production The production and assembly process is simple and the use time is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

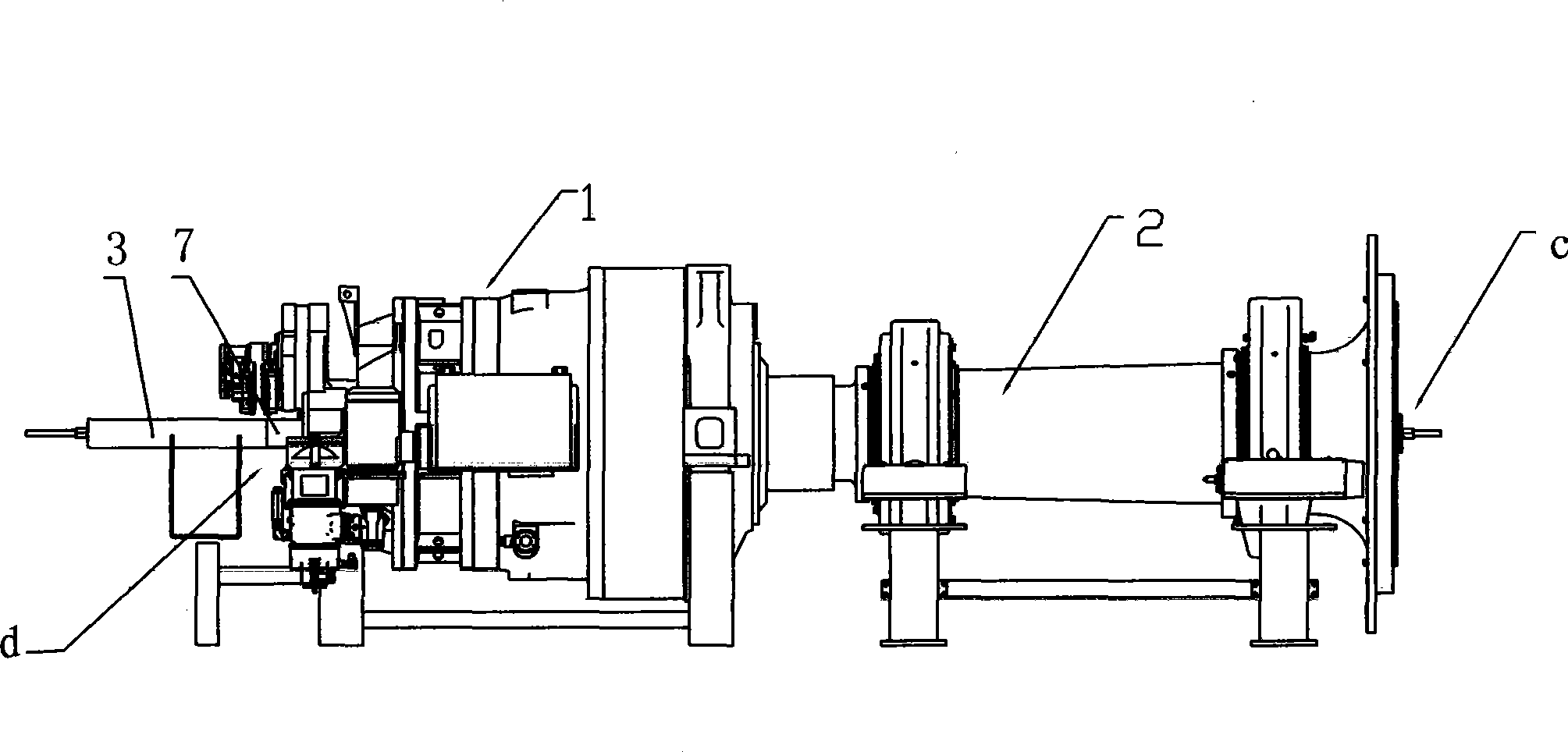

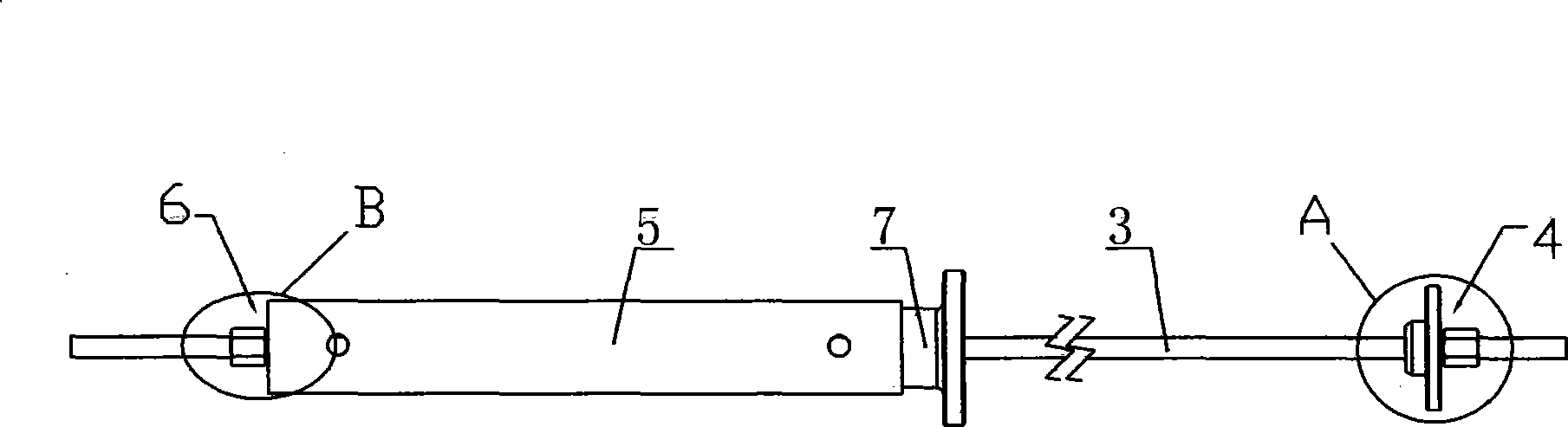

[0020] A method for assembling a main shaft and a gearbox of a large-scale wind power generator, such as figure 1 , 2 As shown, the assembly steps are as follows:

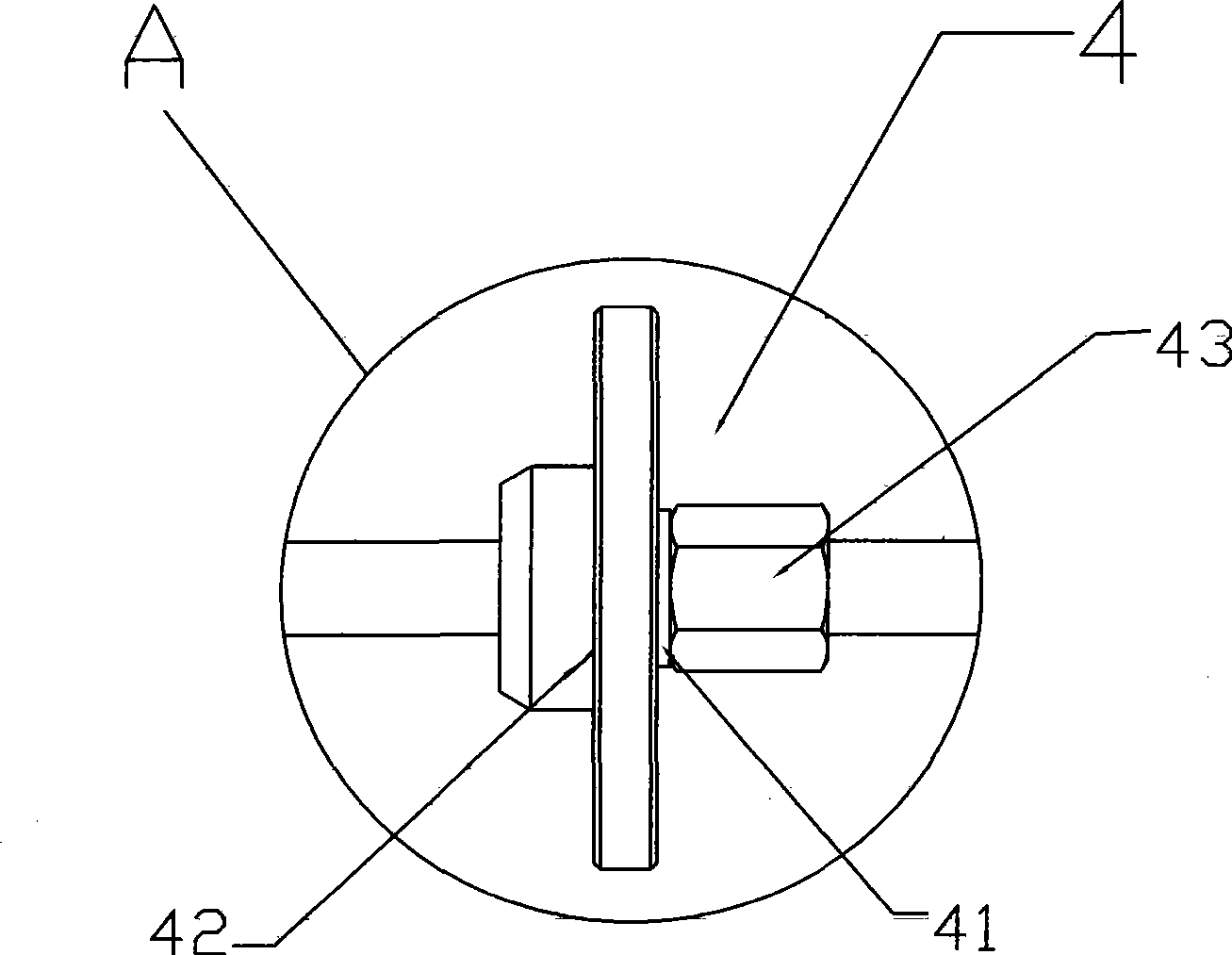

[0021] a. First place the gear box 1 horizontally on the gear box rack to ensure that the main shaft hole of the gear box is basically level. The gear box 1 is provided with a hole that penetrates the gear box opposite to the main shaft hole so that the pull rod 3 behind can be Pass through both ends of the gear box 1; b. Lift the hollow main shaft 2 horizontally with a sling, and align the connection with the gear box 1 with the installation position of the gear box; c. Adjust the height and left and right positions of the crown block to make the main shaft 2 and the gear box The shaft hole of the main shaft is coaxial; d. Use a pull rod 3 to pass through the hole of the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com