Shrapnel bullet loading ejector and ejecting method

A technology of sub-munition and ejector, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of low degree of automation, low work efficiency, cumbersome operation, etc., and achieve the effect of high degree of automation, high work efficiency and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A push-out machine for submunition bullet charges.

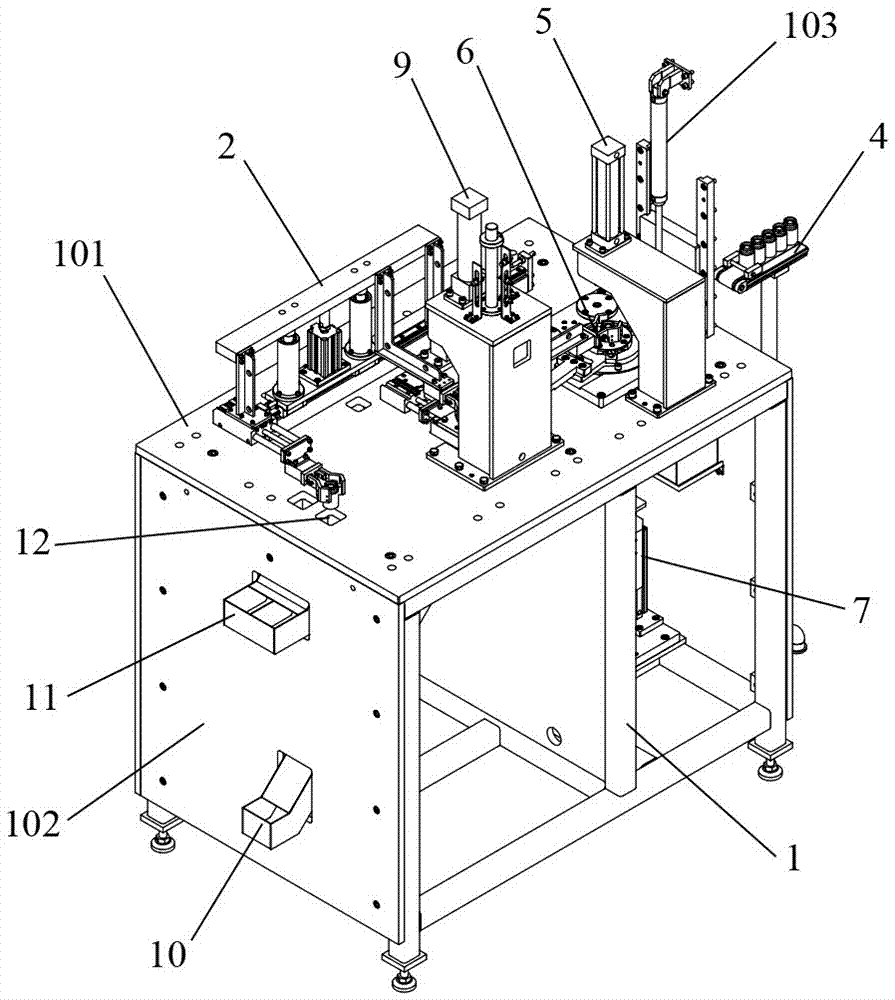

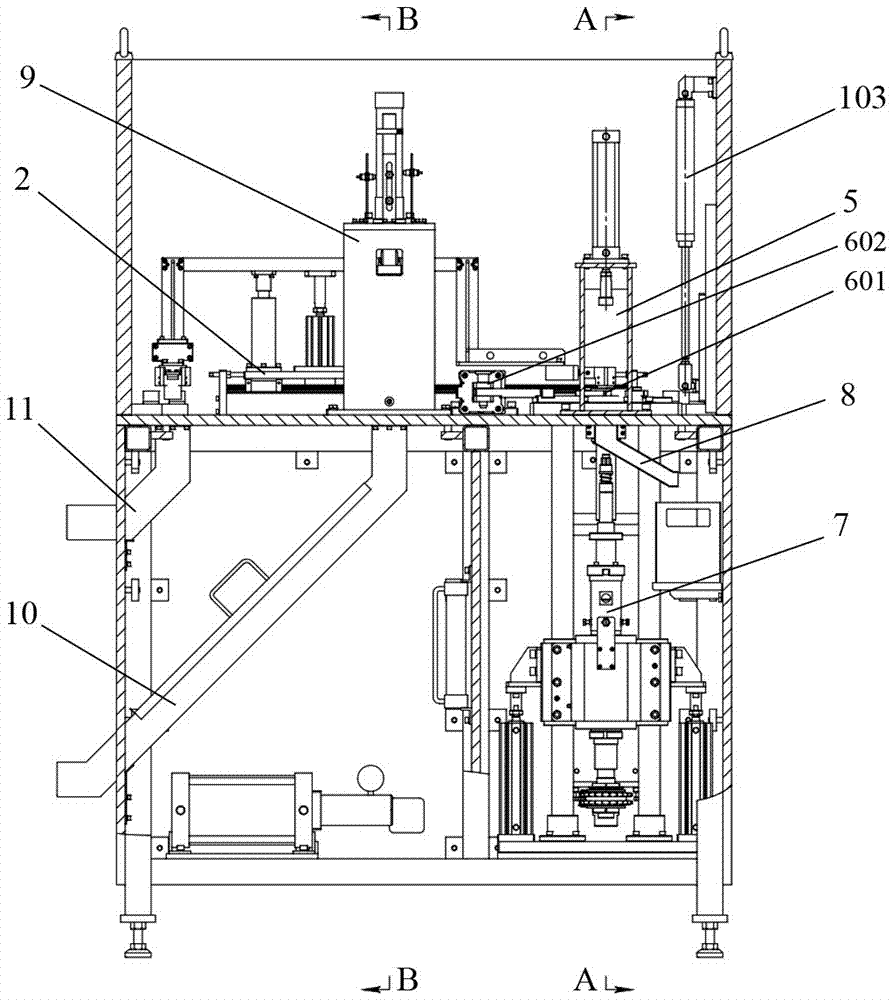

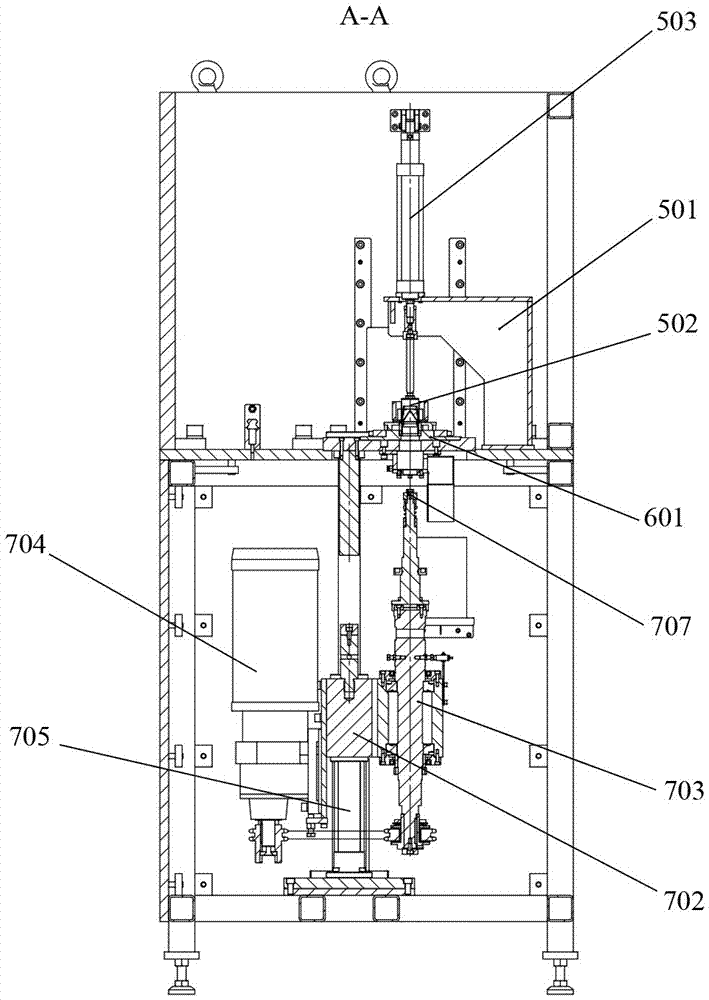

[0034] Such as figure 1 and 2 As shown, the push-out machine for the submunition bullet charge of the present invention includes a frame 1, a stepping conveying device 2, a dissolving device 3, a bullet temporary storage device 4, a pressing and unloading device, a pushing device 9, a feeding device, a pneumatic system and Electronic control system and other parts.

[0035] Frame 1 is a frame body assembled by several frame rods. An interlayer plate 101 is horizontally arranged in the middle of the frame body, and the frame 1 is divided into upper and lower layers. A steel plate protective cover 102 is arranged outside the frame 1. Play a safety protection effect, dissolving device 3 and bullet temporary storage device 4 are positioned at the outside of protective cover 102, be provided with safety door on the protective cover 102 sidewalls near bullet temporary storage device 4, safety door links to e...

Embodiment 2

[0049] Embodiment 2: the method for pushing out the submunition bullet charge.

[0050] The method for pushing out the submunition bullet charge of the present invention comprises the following steps:

[0051] a. Set a set of ejection machine for the above-mentioned submunition bullet charges.

[0052] b. Turn on the upper liquid pump on the dissolving device 3, pump the epoxy resin dissolving agent into the dissolving tank 302, use the feeding manipulator 303 to put the bullet into the dissolving tank 302, make the bullet body upward, and the jet of the drug-shaped cover faces down, and make the liquid level of the solution in the dissolving tank 302 submerge the pressure ring portion of the bullet, and soak for 30-45 minutes. After soaking, use the feeding manipulator 303 to move the bullet to the bullet temporary storage device 4.

[0053] c. Start the stepping conveying device 2, first push the horizontal sliding seat 202 by the translation cylinder 203 to drive the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com