Cabin opening type ammunition decomposition truck

A technology of ammunition and cabin type, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., to achieve the effects of expanding the scope of application, high-efficiency decomposition, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

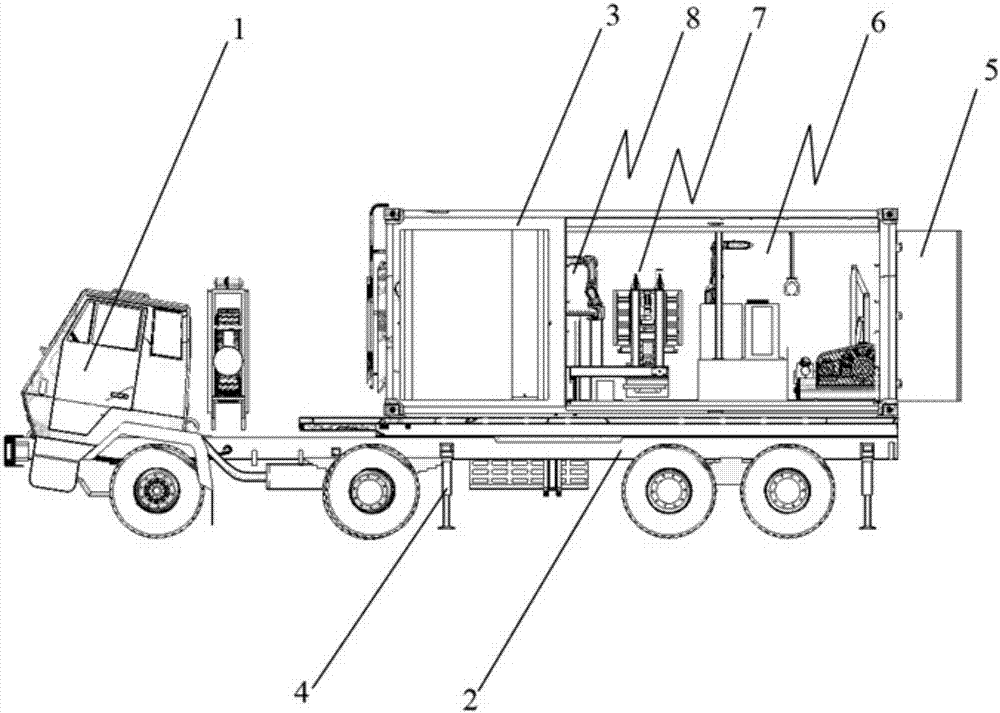

[0050] Such as figure 1 As shown, the open-cabin ammunition decomposition vehicle of the present invention mainly includes a power locomotive 1, a compartment connected to the power locomotive 1, and an open-cabin ammunition disassembly system arranged in the compartment. The power locomotive 1 is used to provide power for the operation of the whole vehicle and drive the carriage to move. The compartment is used to carry the open-type ammunition decomposition system, including the chassis 2 and the compartment 3. Four jacks 4 are arranged under the chassis 2 to meet the stability requirements of the vehicle body during parking operation. On both sides of the compartment 3 and the rear side are respectively provided with a compartment door 5, so that the operator can check the status of each part inside the compartment outside the compartment. A boarding ladder is hung on the right side of the rear end of the car body 3, so that the operator can get on and off the car, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com