Gas-saving type gas supercharger using double activation pistons

A technology of gas supercharger and driving piston, applied in fluid pressure converter, mechanical equipment, etc., can solve the problem of wasting gas consumption of driving gas of supercharger, and achieve the effect of improving supercharging efficiency and saving driving gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

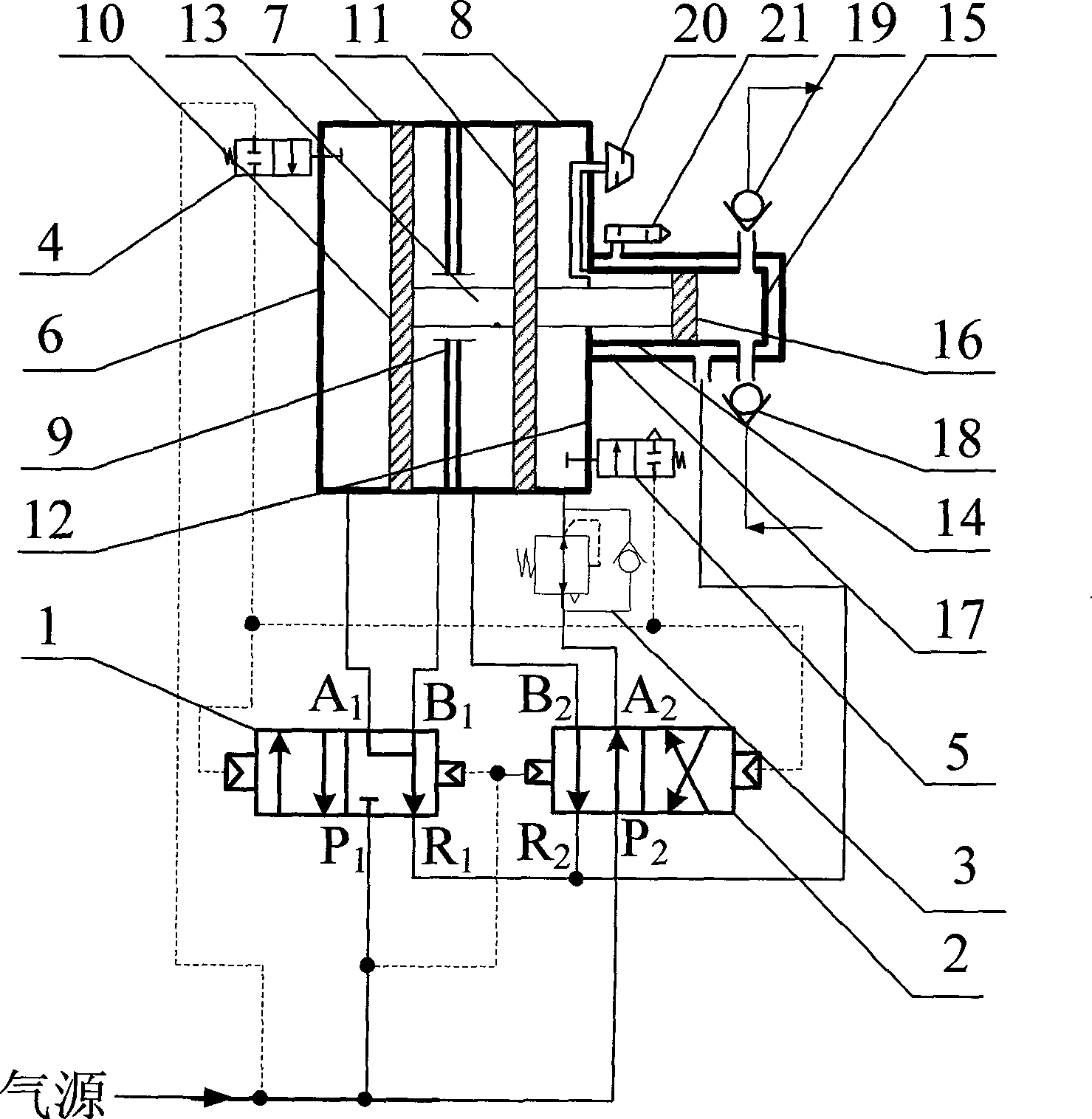

[0009] Such as figure 1 As shown, the present invention includes: first reversing valve 1, second reversing valve 2, pressure reducing valve group 3, left pilot valve 4, right pilot valve 5, first drive chamber end cover 6, first drive chamber 7 , the second driving chamber 8, the partition wall of the driving chamber 9, the first driving piston 10, the second driving piston 11, the second driving chamber end cover 12, the piston connecting rod 13, the pressurized cylinder block 14, the pressurized chamber end cover 15 , booster piston 16, cooling cylinder liner 17, intake check valve 18, exhaust check valve 19, bearing breathing port 20 and exhaust muffler 21; the first reversing valve 1 and the left pilot valve 4 are installed on In the end cover 6 of the first drive chamber, the second reversing valve 2, the right pilot valve 5 and the pressure reducing valve group 3 are installed in the end cover 12 of the second drive chamber, and the piston connecting rod 13 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com