LED module group with cooling structure

A technology of light emitting diodes and heat dissipation structures, which is applied to semiconductor devices, light sources, point light sources, etc. of light emitting elements, can solve the problems of narrow illumination range and poor illumination effect, and achieve the effect of expanding illumination angle and range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

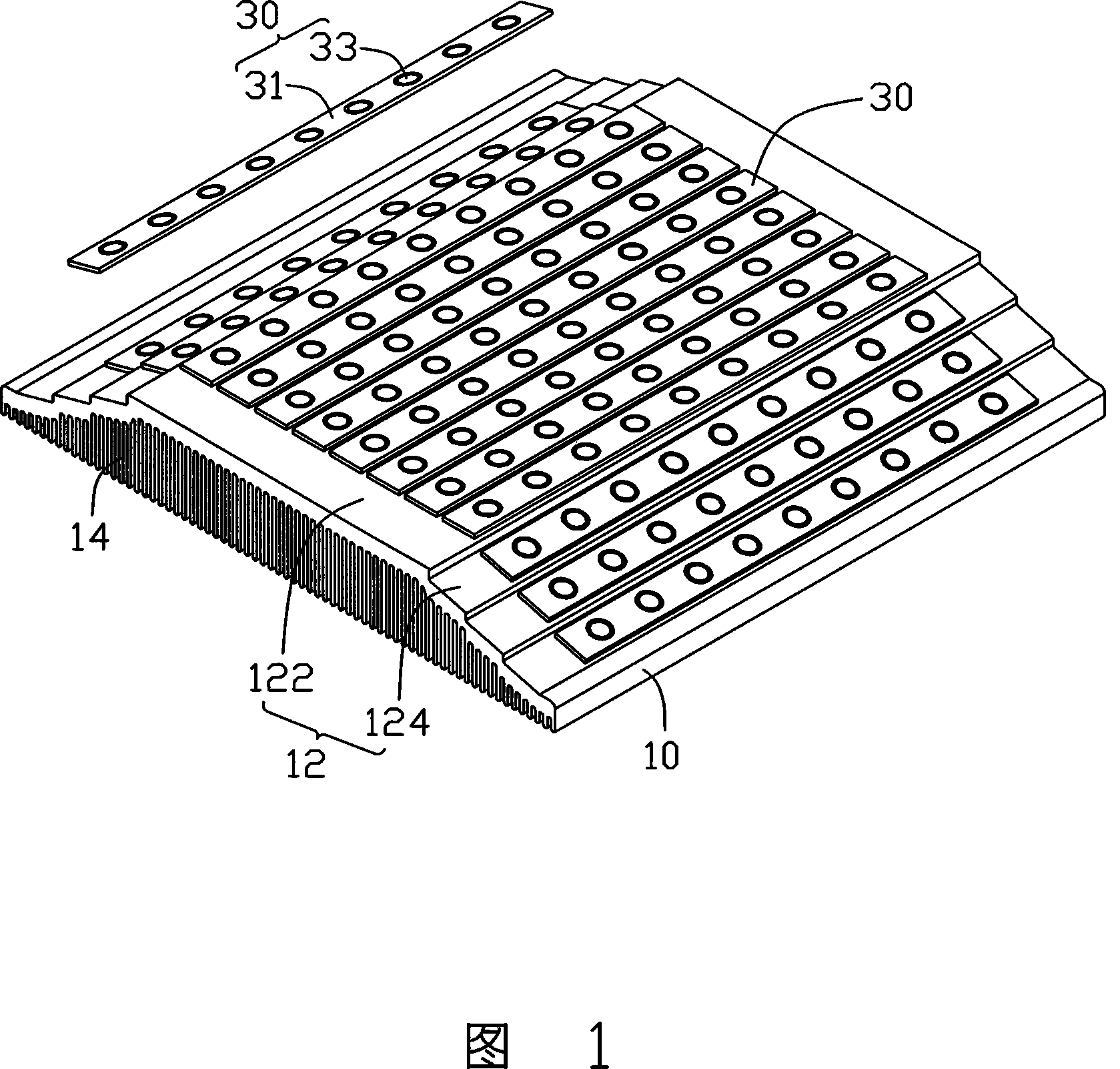

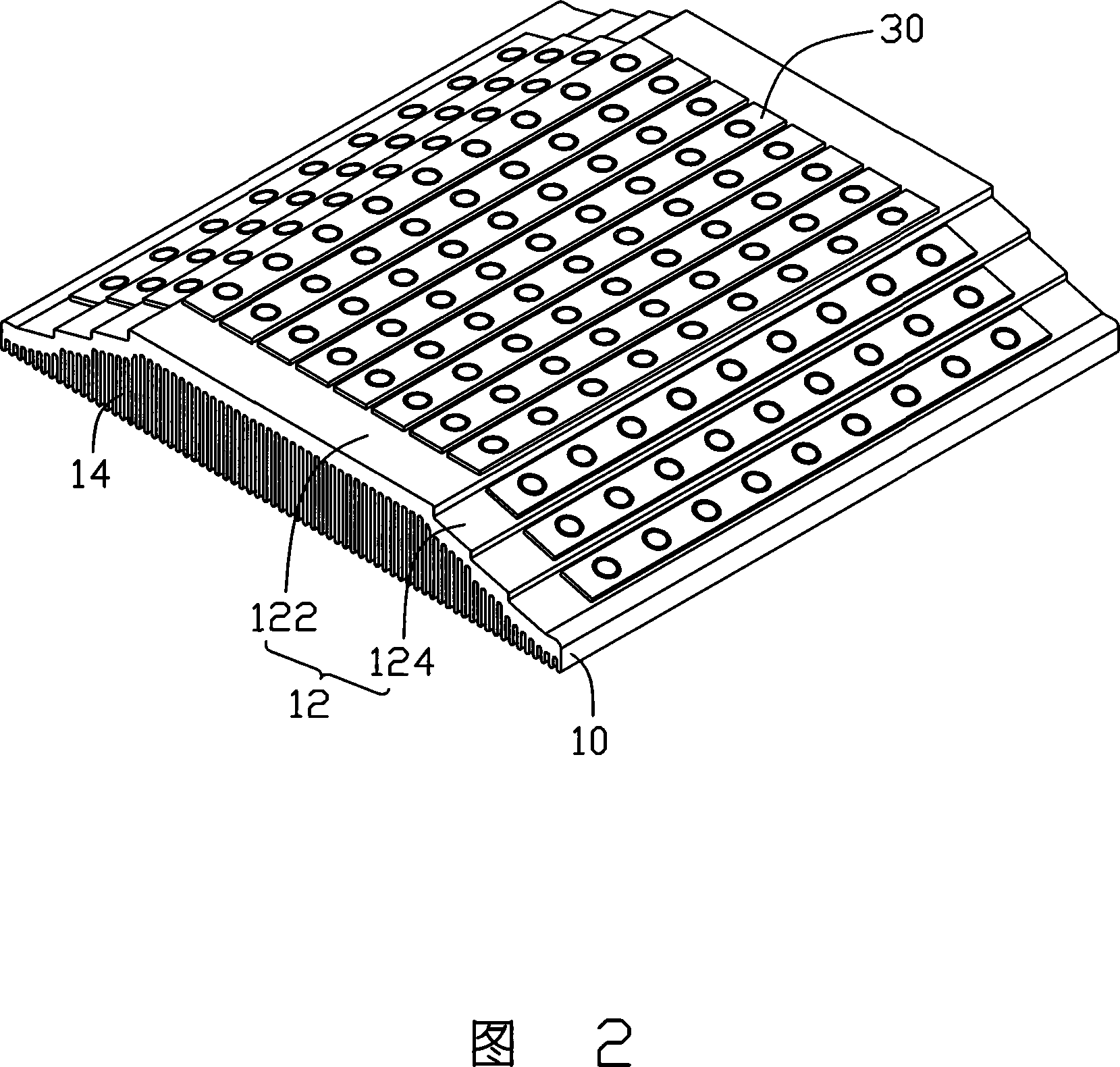

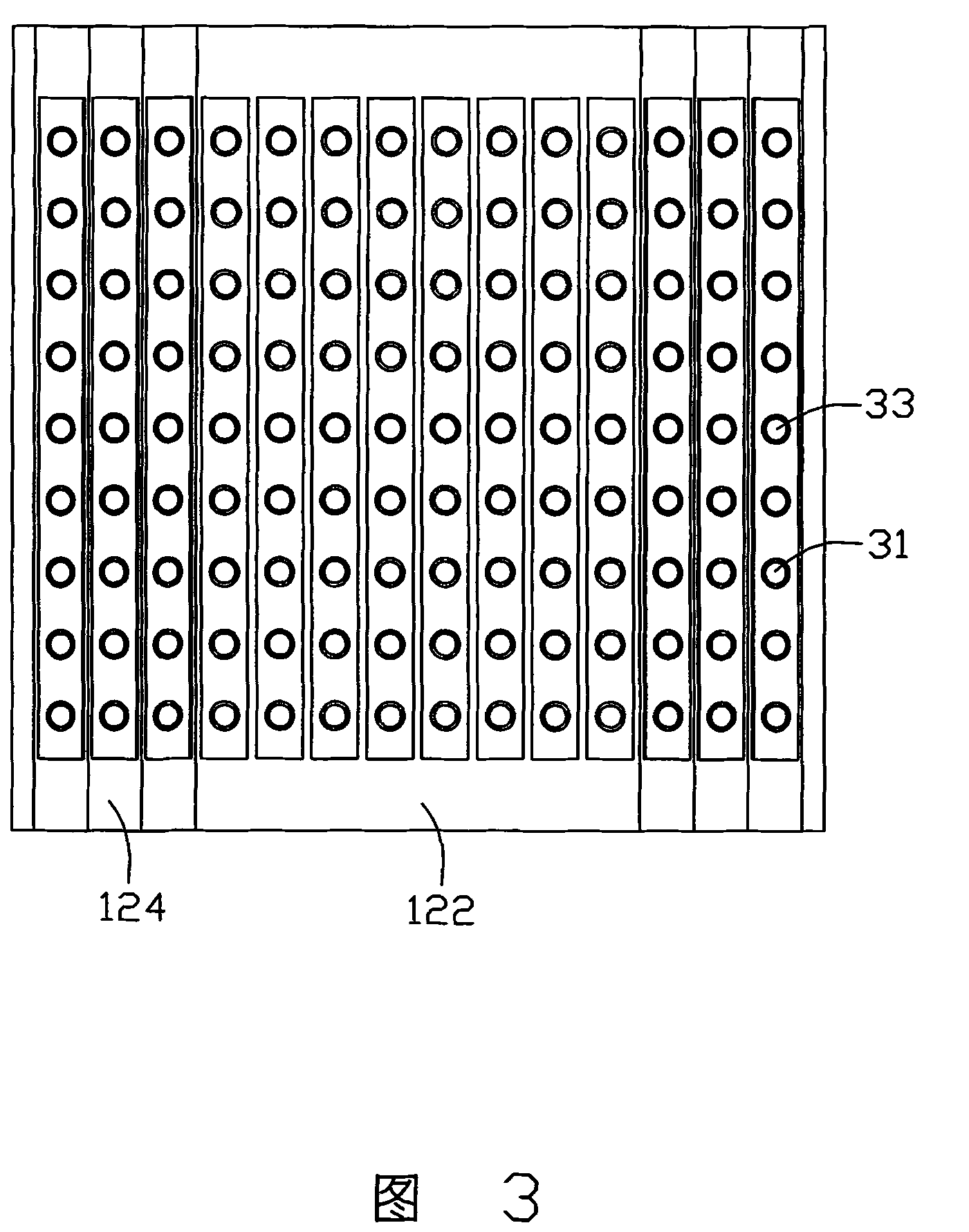

[0013] Such as figure 1 and figure 2 As shown, the LED module with heat dissipation structure of the present invention includes a heat sink 10 and a plurality of LED units 30 attached to the heat sink 10 .

[0014] The radiator 10 is integrally formed by extrusion, and includes a heat conduction seat 12 and a plurality of heat dissipation fins 14 extending outward from the heat conduction seat 12 . The cross-section of the radiator 10 is roughly trapezoidal. The heat conducting seat 12 is substantially V-shaped. The heat conducting base 12 has a first heat absorbing portion 122 and two second heat absorbing portions 124 obliquely extending outward from opposite sides of the first heat absorbing portion 122 . Each second heat absorbing portion 124 includes several steps (not shown). The first heat-absorbing portion 122 has a planar first heat-absorbing surface (not shown) for attaching the above-mentioned LED unit 30 . Each step of the second heat absorbing portion 124 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com