Method of bonding a film to a curved substrate

A film and substrate technology, applied in the field of equipment to realize this method, can solve the problem of the entry of fine dust and dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

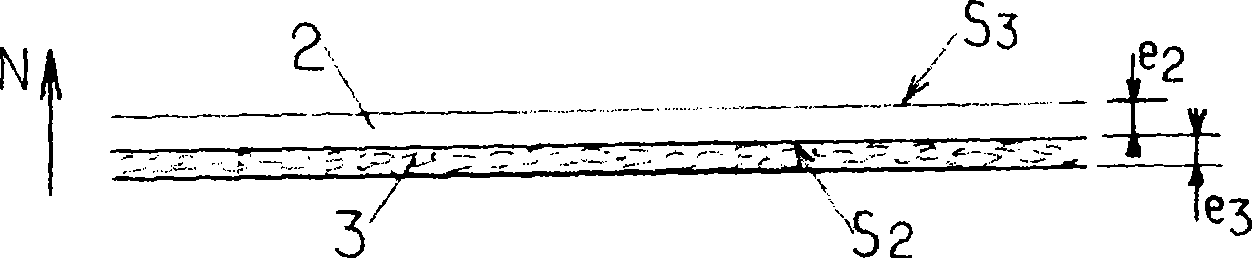

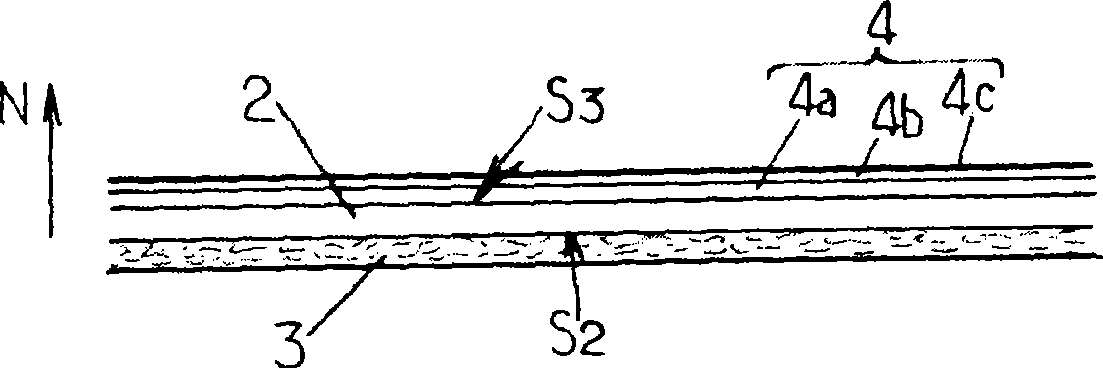

[0033] In order to make these drawings more clear, the size of the components shown in the drawings is not according to the actual size or not in proportion to the actual size. In addition, the same symbols in different drawings indicate the same elements, for example, N that appears repeatedly in multiple drawings indicates a fixed direction.

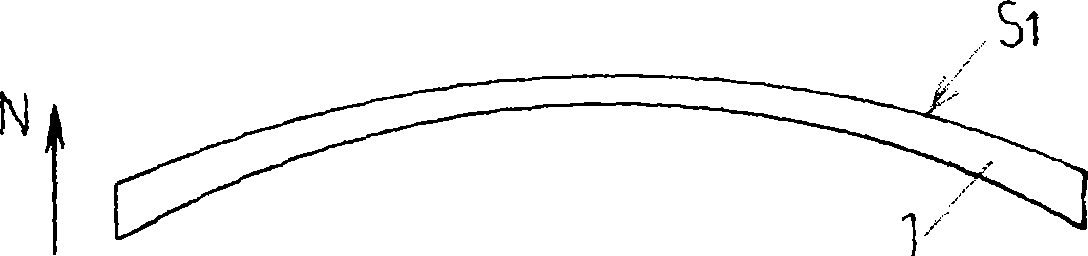

[0034] according to figure 1 As shown, the substrate 1 consists of an ophthalmic lens. These lenses may be spectacle lens blanks, that is, lenses that have not been cut to the size of the frame for the purpose of fitting the lens into the frame. The lens 1 may consist of any material commonly used in the ophthalmic field, which may be a mineral material, an organic material, or may be a composite. It may be, for example, a corrective or non-corrective lens of a monofocal, bifocal, trifocal or modified type. Optionally, such lenses may be bulk-tinted. It will be appreciated that the invention is independent of the type of lens used....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com