Rolling bearing having two inner rings and a seal arrangement for sealing the parting joint between the inner rings

A technology for rolling bearings and sealing rings, applied in the field of rolling bearings including two inner rings and a sealing device for sealing the boundary between the inner rings, can solve the problem of outflow of lubricant, insufficient sealing, deterioration of rolling bearing characteristics, etc. problem, to achieve the effect of good sealing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

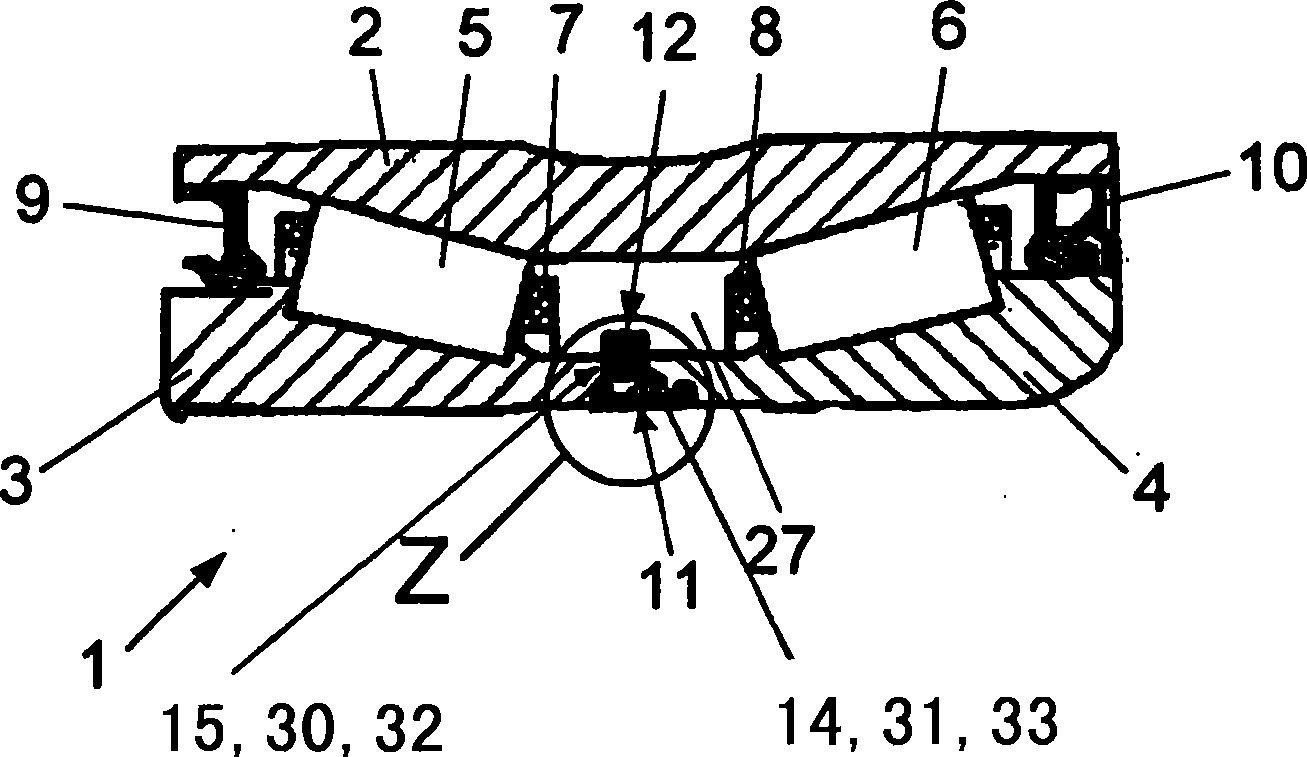

[0035] Accordingly, figure 1 The rolling bearing 1 shown in is designed as a double-row tapered roller bearing, but it can also be a different type of rolling bearing, which has at least one outer ring 2 and at least two inner rings 3 , 4 which are in close contact with each other at the end faces.

[0036]Rolling bodies 5 , 6 configured as tapered rollers are arranged in a receiving space 27 formed by these bearing races 2 , 3 , 4 , which are axially passed through known per se seals 9 , 10 with rubber and sheet metal. The construction is sealed against the ingress of foreign substances and the escape of lubricants, wherein the rolling elements 5 , 6 of each row are held in a separate cage 7 or 8 .

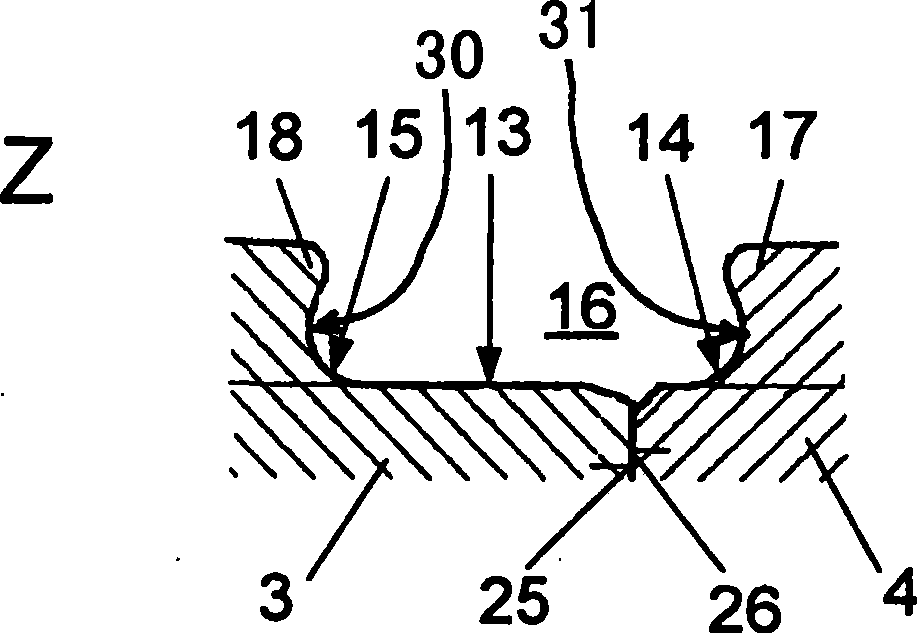

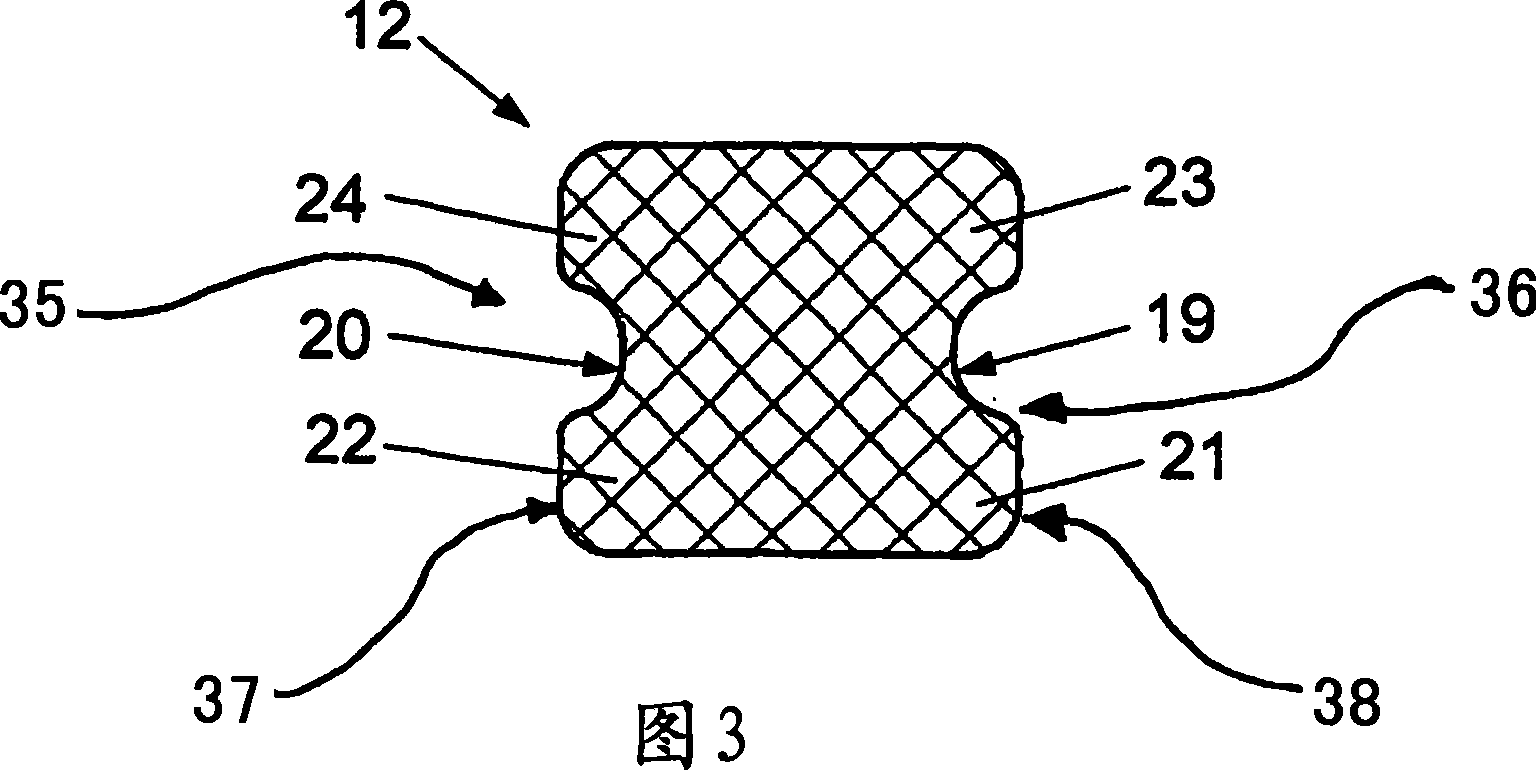

[0037] The two inner rings 3 , 4 each have a radial groove in the region of their mutually facing end faces 25 or 26 on the radial inside, ie on the inside remote from the raceways of the rolling elements 5 and 6 , in which Insert the sides of a U-shaped sheet metal ring as ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com