Cutting machine and sheet feeding cutting method

A cutting machine and sheet material technology, which is applied in the field of cutting machines, can solve the problems of commodity value generation, easy generation of cutting residues, and difficulty in cleaning connection points, etc., to prevent cutting residues, shorten waiting time, and improve cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

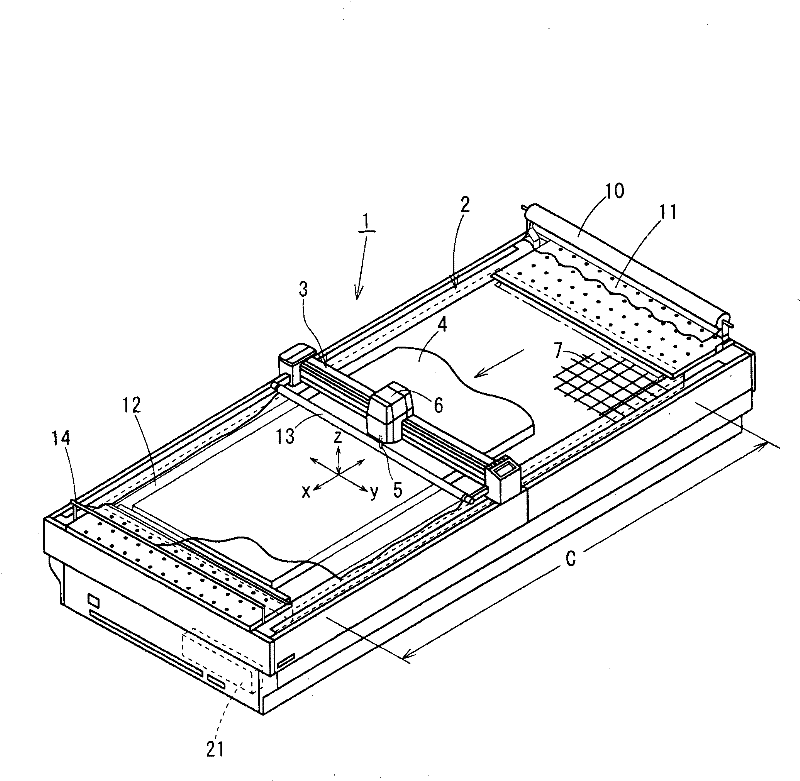

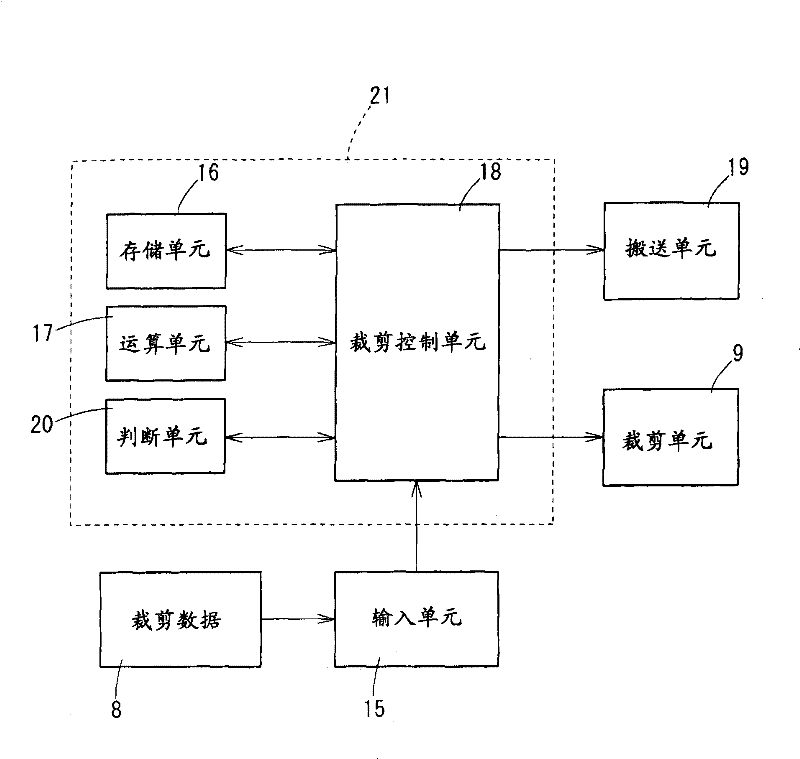

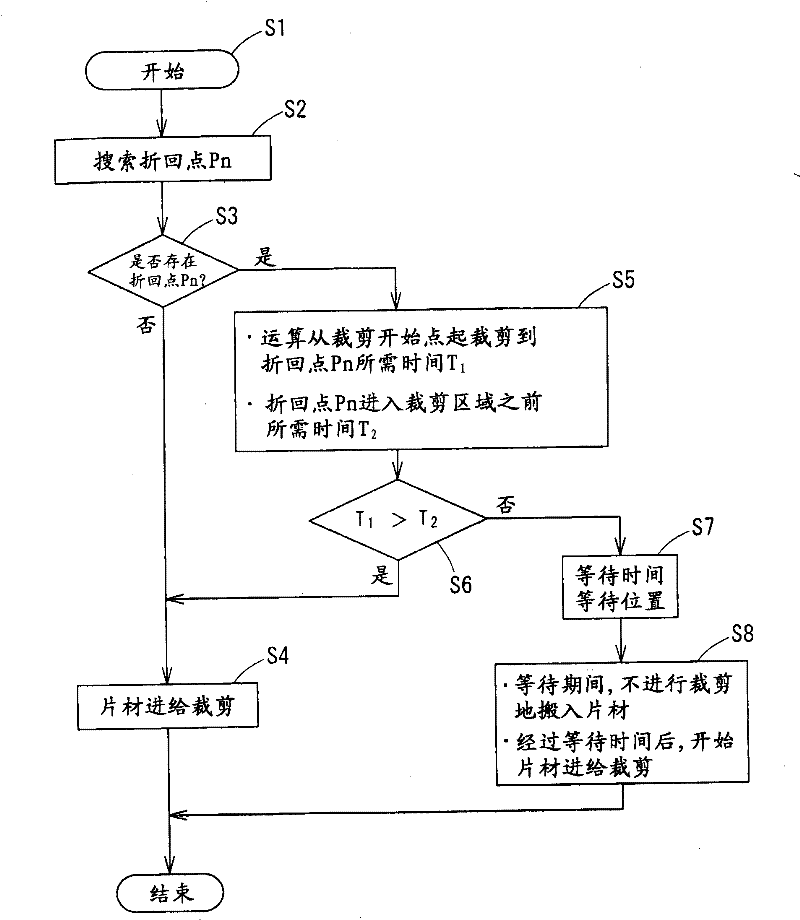

[0025] figure 1 It is a perspective view showing the appearance of the cutting machine 1, and reference numeral 1 in the drawing indicates the cutting machine as a whole. The cutting carriage 3 is arranged on the cutting table 2 of the cutting machine 1 .

[0026] The cutting carriage 3 can move along its length direction on the cutting table 2, that is, the conveying direction (X-axis direction) of the sheet 4, and the cutting head 6 with the cutting knife 5 moves along the width direction of the sheet 4 on the cutting carriage 3. That is, the cutting carriage 3 is movably provided in the Y-axis direction perpendicular to the conveying direction, and the cutting blade 5 constitutes a cutting unit 9 for cutting the sheet 4 .

[0027] Furthermore, the cutting blade 5 can be raised and lowered in the Z-axis direction via a lifting unit (not shown) assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com