Gearshift of hand breast pump

A gear shifting device and breast pump technology, applied to breast pumps, etc., can solve problems such as difficult to balance reset, narrow the negative pressure range, and unfavorable breast protection, so as to prevent breast diseases and expand the range of negative pressure generation Effect

Inactive Publication Date: 2009-07-08

张连盛

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

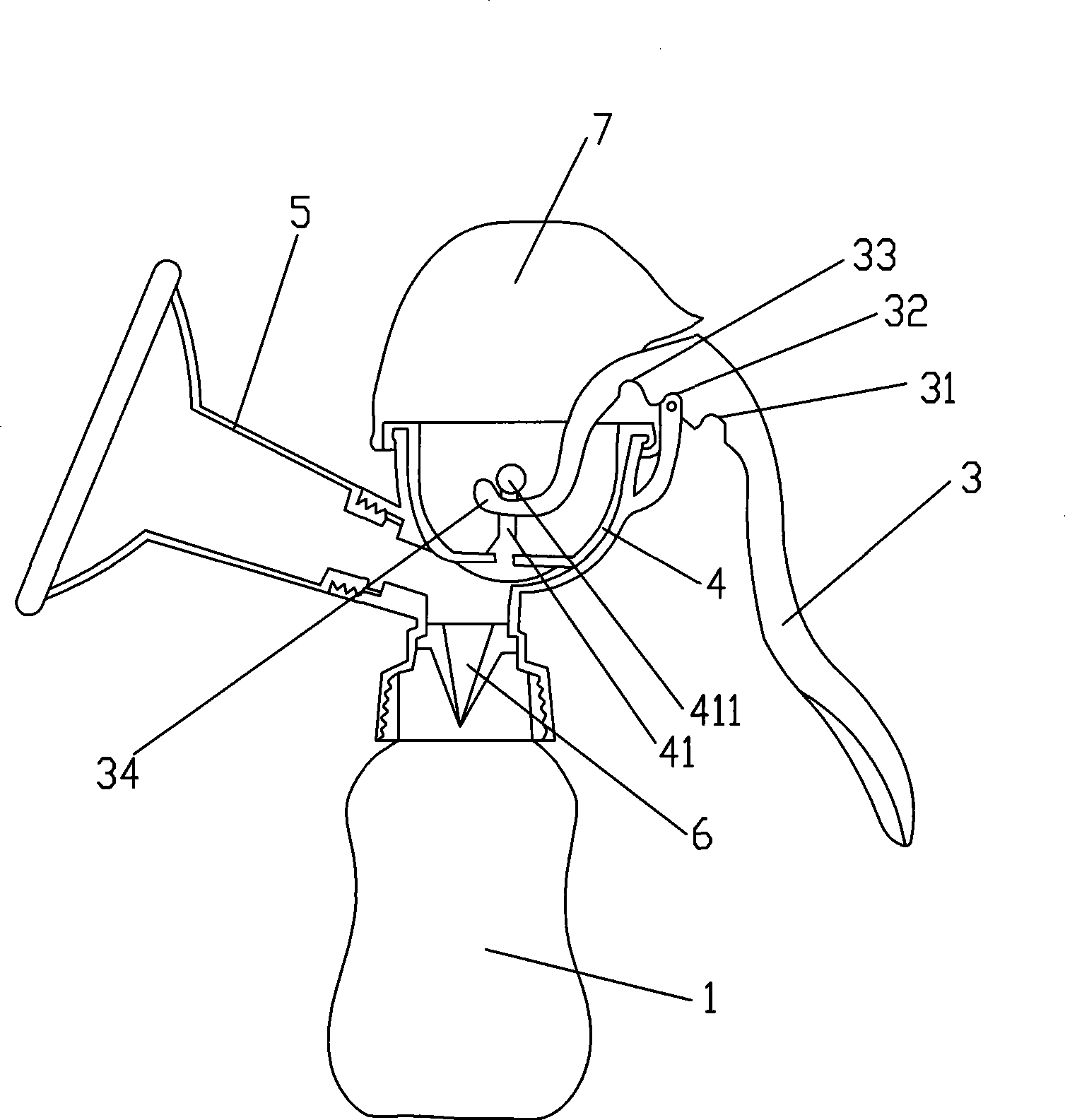

AI Technical Summary

Problems solved by technology

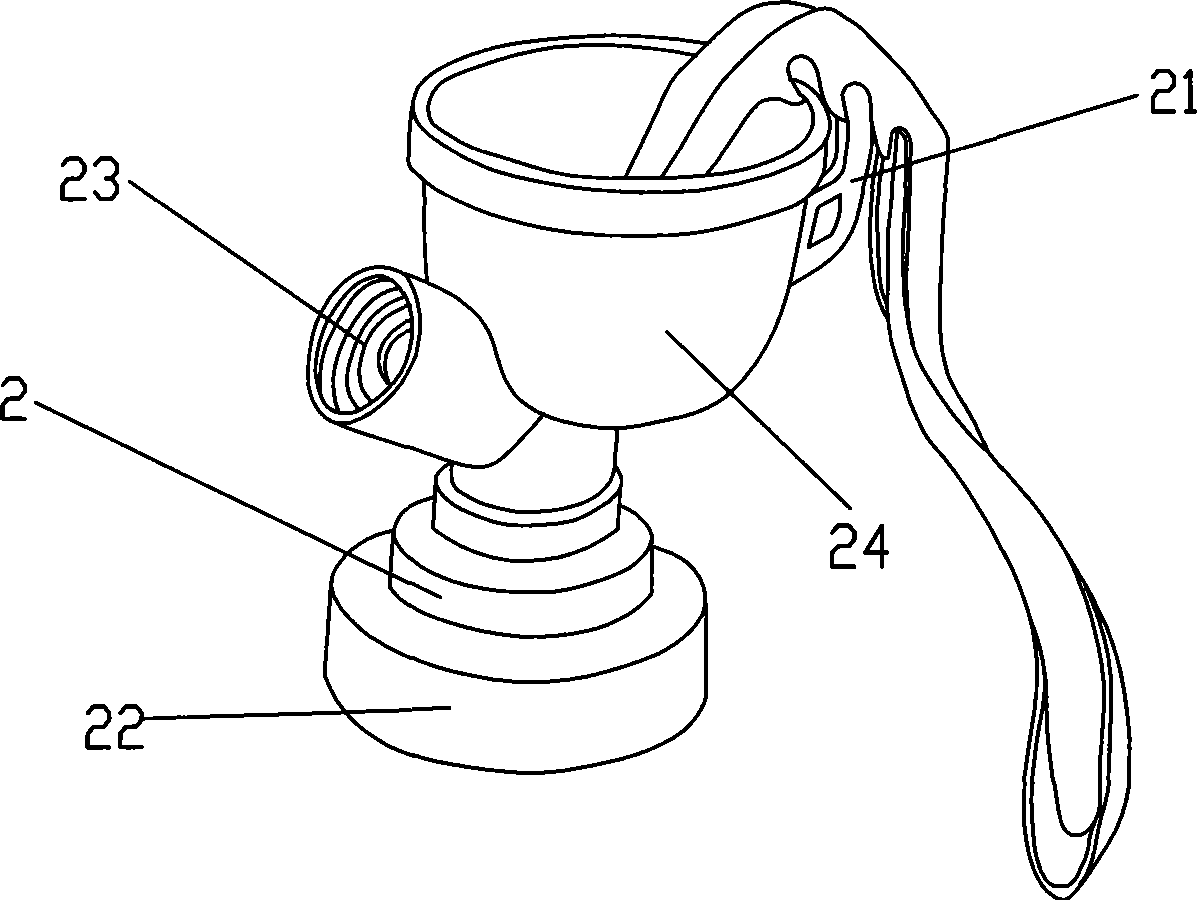

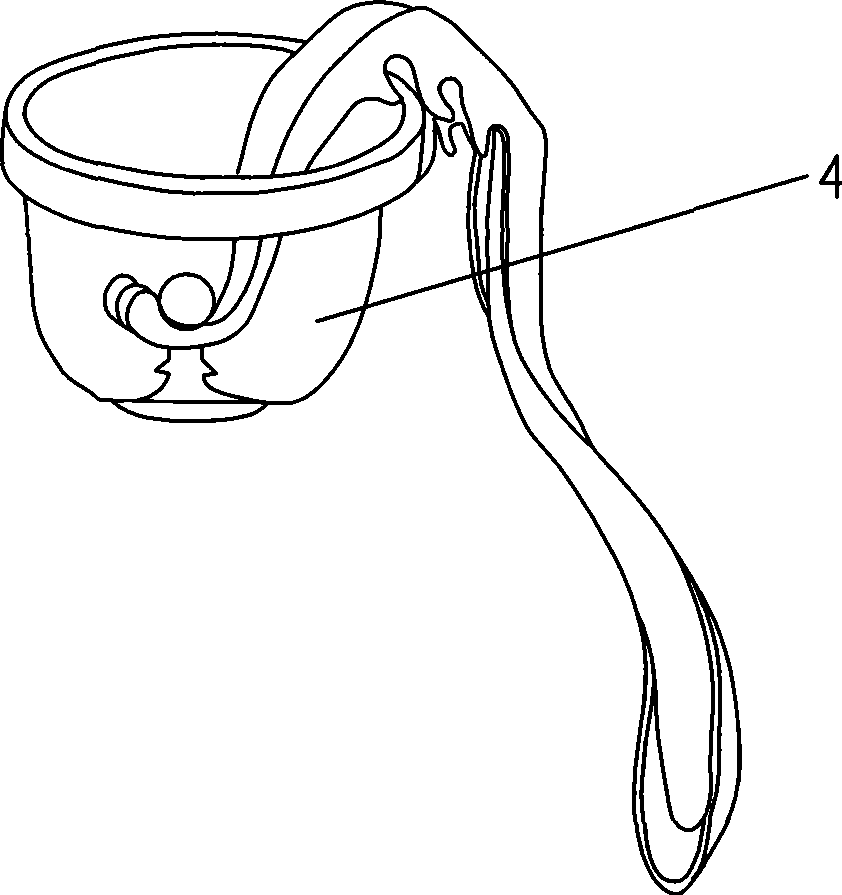

It is composed of a feeding bottle, a negative pressure generating cover threadedly connected with the feeding bottle, a breast suction plate connected with the negative pressure generating cover, and a sky cover on the negative pressure generating cover. The negative pressure generating cover is provided with a feeding bottle threaded interface, The threaded interface of the sucking pan, the negative pressure piston shell, the negative pressure piston covers the inner surface of the negative pressure piston shell, and is tightly connected with the negative pressure piston shell, the threaded interface of the breast sucking pan is exposed at the bottom of the negative pressure piston shell The negative pressure piston part and the silicone valve located at the mouth of the feeding bottle together form a negative pressure space in the negative pressure generating cover, that is, when the negative pressure piston is lifted upwards, the silicone valve is closed, and the negative pressure space is enlarged to generate negative pressure. When the negative pressure piston resets downward, the negative pressure gradually disappears, the silicone valve opens, and the breast milk enters the feeding bottle; a lifting rod is arranged at the bottom of the negative pressure piston, and the lifting rod cooperates with one end of the pressing rod to pass One end of the pressure rod is pried up to drive the lifting rod up, and the bottom part of the negative pressure piston is gradually lifted, the other end of the pressure rod is exposed outside the negative pressure piston shell, and the fulcrum of the pressure rod is set on the negative pressure piston shell; the above-mentioned breast pump , because the longitudinal section of the bottom of the negative pressure piston connected to the lifting rod is approximately square, it is difficult for the negative pressure piston to reset evenly by relying on its own tension, and because its own tension is small, the reset time is prolonged, so the bottom shape of the negative pressure piston It needs to be further improved; at the same time, the existing breast pump only has one force arm to cooperate with the fulcrum due to the pressure rod, so the lifting height of the lifting rod is limited, the negative pressure interval can be reduced, and it cannot withstand the negative pressure according to the human breast. It is not conducive to the breast protection of the human body to realize the free adjustment by the ability of pressing the suction force. Using the above-mentioned breast pump is still easy to cause breast diseases of the human body. Therefore, further improvement is required on this basis.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 2 example

[0027] see Figure 7 , the shifting device of the hand-pressed breast pump is the same as the first embodiment, and a human-like mouth silicone inner sleeve 51 is set to cover the surface of the breast-feeding tray 5, thereby forming a hand-pressed bionic breast pump.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a shifting device of a hand breast pump which is arranged at a negative pressure generating cover. A milk bottle interface, a sucking plate interface and a negative pressure piston casing are arranged on the negative pressure generating cover. A negative pressure piston is covered on the inner surface of the negative pressure piston casing. A lifting rod is arranged on the bottom of the negative pressure piston. A fulcrum of a compression bar is arranged on the negative piston casing. One end of the compression bar is matched with the lifting rod, and the other end of the compression bar is exposed out of the negative piston casing. A plurality of supporting ports are distributed on the compression rod of the breast pump with intervals. One supporting port can be selected to be matched with the fulcrum arranged on the negative piston casing. The structure of a plurality of supporting ports is adopted by the compression bar. Therefore, when in use, the supporting ports can be changed according to the comfort requirements to the negative pressure absorption force bearing of human body. The negative pressure region is expanded. The milk sucking requirements of lactating breasts under various physiological states can be satisfied. Breast diseases can be avoided. And breast swelling and body beautifying effects can be realized.

Description

technical field [0001] The invention relates to a feeding bottle device for suctioning breast milk with negative pressure, in particular to a negative pressure generating device for a hand-pressed breast pump. Background technique [0002] At present, a kind of breast pump of being sold on the market. It is composed of a feeding bottle, a negative pressure generating cover threadedly connected with the feeding bottle, a breast suction plate connected with the negative pressure generating cover, and a sky cover on the negative pressure generating cover. The negative pressure generating cover is provided with a feeding bottle threaded interface, The threaded interface of the sucking pan, the negative pressure piston shell, the negative pressure piston covers the inner surface of the negative pressure piston shell, and is tightly connected with the negative pressure piston shell, the threaded interface of the breast sucking pan is exposed at the bottom of the negative pressure ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61M1/06

Inventor 高杰张连盛

Owner 张连盛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com